452515

• If you have a tumble dryer of the same dimensions, you can

place it on top of the washing machine.

To ensure correct operation of the appliance, water

pressure inlet must be between 0,05 and 0,8 MPa.

Minimum water pressure can be established by measuring

the quantity of poured out water. 3 litres of water must be

poured out from completely opened tap in 15 seconds.

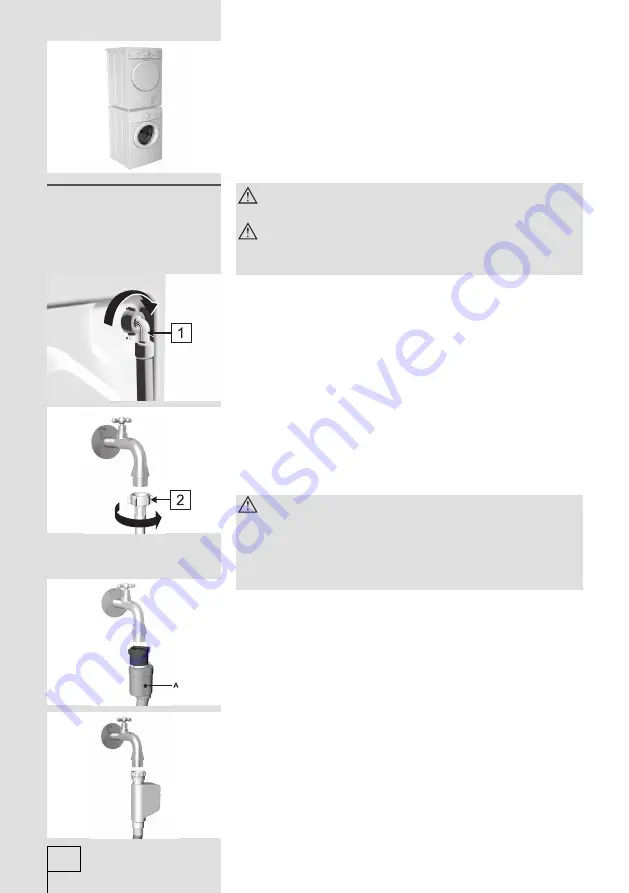

• Take the water inlet hose from the drum and attach the inlet hose

angle extension (1) to the washing machine by screwing it onto

the provided thread (certain models only).

• Insert the gasket with a

fi

lter net into the straight inlet hose

attachment nut (2) and screw the nut onto the water tap. (With

some models, the gasket with

fi

lter net is already

fi

tted and any

additional

fi

tting into the nut on the straight attachment is not

required).

• If your model has connections for both hot and cold water, then

connect one hose to the cold water supply (blue wing nut or blue

mark on the hose) and the other one to the hot water supply (red

wing nut or red mark on the hose), as indicated on the back wall of

the appliance (letters C and H) (C - cold; H – hot).

The inlet hose should be tightened manually,

fi

rmly enough

to prevent any leaks. After tightening the hose, check for

any leaks.

Use of pliers, wrenches, or other similar tools is not

allowed when installing the hose, as these tools can

damage the nut thread.

Partial Aqua-stop (water stop system)

In case of damage on the interior pipe, leaking is prevented by

automatic closing system which stops water inlet to the machine. In

such cases display A turns red.

Inlet pipe must be replaced.

Complete Aqua-stop

(certain models only)

In case of damage on the interior pipe, leaking is prevented by

automatic closing system which stops water inlet to the machine.

Security system also detects whether there is any water leakage

within the interior of the machine. In such cases washing is

suspended, machine switches on the pump and signals error.

Water inlet connection

6

Summary of Contents for EWM246KWIT

Page 1: ...Instructions for Use Washing machine...

Page 30: ...452515 30...

Page 31: ......

Page 32: ...PS PG0A ETN en 11 13...