Exit: exit “counterpoint operation” interface, enter “operation interface”, current state have no change.

When working area display aligning arm in, then status bar location of aligning arm: external;

When working area display vacuum open, then vacuum state in status: “close”.

When status bar display “high speed mode”, express move speed is high, when status bar display “low

speed mode”, express move speed is low. This function effect in counterpoint interface.

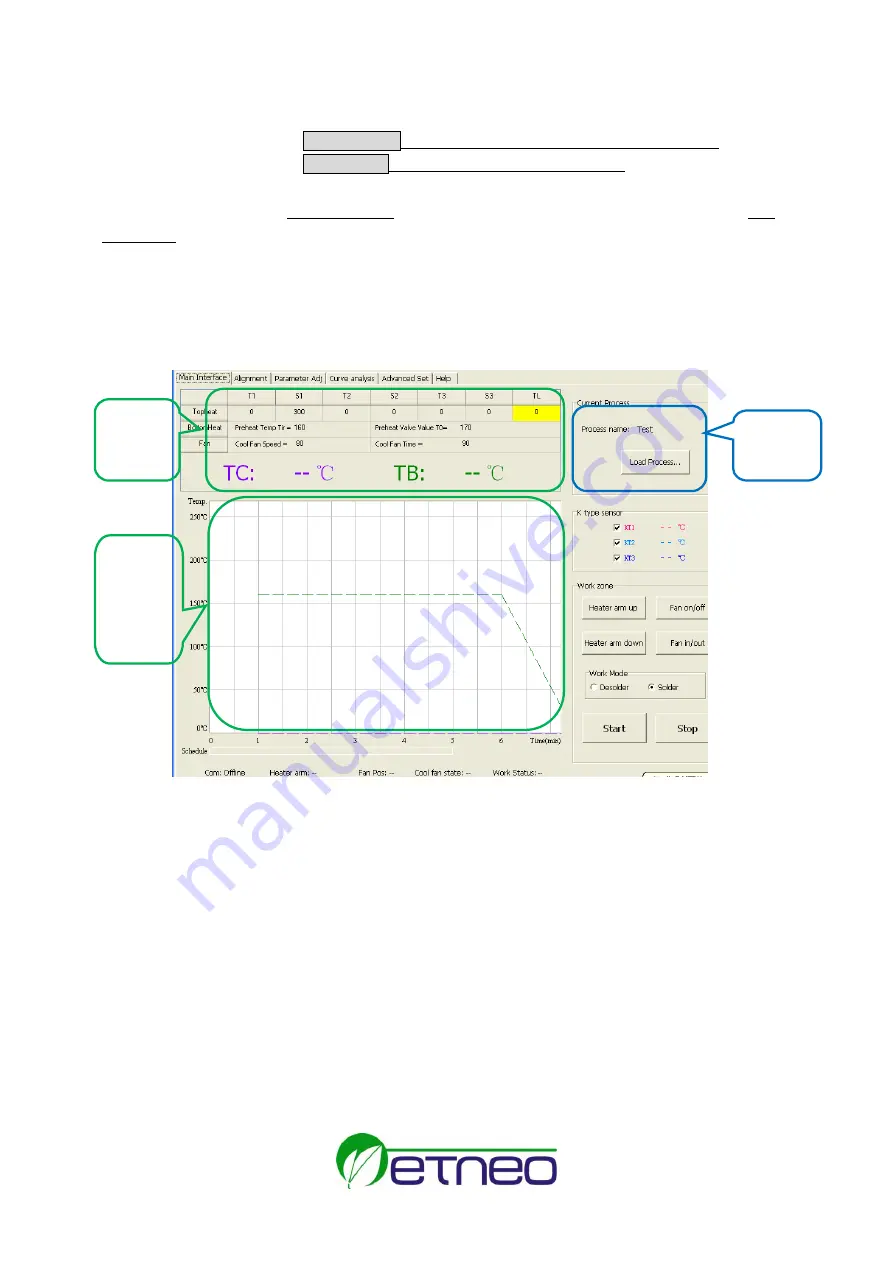

11.3 parameter testing interface

Parameter testing interface: when solder or desolder new chip, by this display, we can do solder or desolder

testing.

Counterpoint height: memory setting height. After setting, auto memory this height, the same

specification chip counterpoint, call save flow, do not need adjust counterpoint height.

Counterpoint height cancel: cancel saved counterpoint height.

Suck height: memory sucking height which have be set. After setting, auto memory this height, when

suck the same chip next time, we can call the saved flow, not need adjust counterpoint

height.

Cancel suck height: cancel suck height which have be saved.

In flow edit display, show goal flow name and technology type

(

desolder/solder

)

、

nozzle size

、

down

distance and heat dissipation air quantity etc.

Down distance: adjust heat head height range, setting range 0~255mm; heat dissipation air quantity

setting range 35~100. (can adjust on the basis of PCB adjust)

After edit parameter in parameter setting display, in“flow edit display”input flow name, appropriate

nozzle size, select flow technology curve is “desolder”

、

or “solder”. And then click “parameter save” and

Parameter

testing

display

Flow edit

display

Parameter

testing

display

Summary of Contents for BGA ETA-H15

Page 2: ......