19

MAINTENANCE

Figure 7. Check Oil Level of Oil Lubricated Bearings

CAUTION

Do not allow brake drums to become

excessively worn or expensive repairs will be

required.

Figure 8. Lug Tightening Sequence

Suspension Alignment & Fastener Torque

The major source of costly repair bills on

suspensions is insufficient torque. After an initial

shakedown run of 1,000 miles and every 25,000 miles

thereafter, nuts on the suspension should be restored to

original torque specifications.

Torque Specifications

Transpro Reyco 21B

U-bolt hi nuts

3/4”

300

300

ft. lbs. ft. lbs.

7/8”

300

300

ft. lbs. ft. lbs.

Torque arm nuts

270

200

ft. lbs. ft. lbs.

Torque arm

55-60

80

clamp nuts

ft. lbs. ft. lbs.

Alignment Adjustment

To assure proper alignment of the suspension,

the following steps should be followed exactly:

1. Locate the trailer on a flat, smooth surface and

disconnect trailer brakes.

2. With the brakes disconnected, roll the trailer

forward and rearward a distance of approximately 10

feet to relieve any binding which might be caused by

turning or braking.

3. Remove the tractor from the trailer and level the

trailer body until it is parallel to the ground, using the

landing gear adjustment. Trailer should be leveled by

measuring from the frame to the ground at the front

and rear hanger.

4. Check to make sure that there is no interference

between the springs and the hanger brackets.

5. Tighten all torque arm bolt nuts and Ubolt nuts to

the torque specified above.

6. Remove hub caps from all four trailer wheels and

install axle extensions on each end of each axle.

7. Install a Bazooka-type kingpin extension and

center the sight level.

8. Measure from the kingpin extension to either end

of the front axle and make necessary adjustments.

9. With the front axle properly aligned, measure

between the axle extensions on either end of each axle

and make necessary adjustments.

10. Remove the axle extension, kingpin extension

and install hub caps.

11. Check the nuts on the adjustable torque arm tube

clamps to insure they are tightened to torque shown

above.

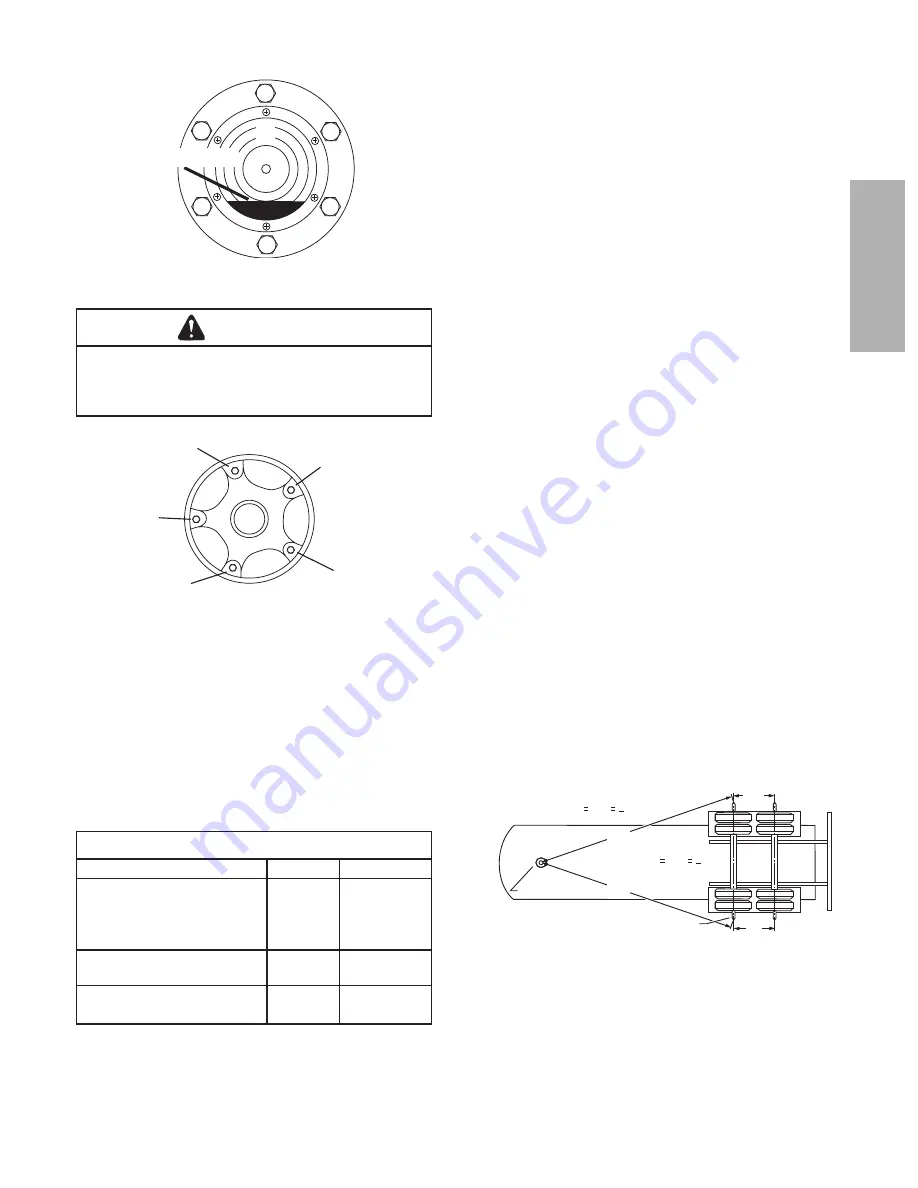

Figure 9. Checking Alignment

Note A. Steps one and two are very important in the

proper alignment of your suspension and should be done

before any attempt is made to align the suspension.

Note B. The slot in the adjustable torque arm should

be located in the down position and in alignment with

the open part of the clamp to insure proper clamping.

ST

EMC

O

HUB S

EA

L

ADD

FULL

FILL TO THIS LEVEL

1

2

3

4

5

S L

S R

L R

L L

+ 1/16

S R

S L

+ 1/16

1 6450076 BAZOOKA

2 6450077 AXLE EXTENSION SET

AXLE EXTENSION SET SHOWN IN PLACE

L R

L L