20

MAINTENANCE

Note C. The adjustable torque arm tube retaining nuts

should be tightened to the torque shown above

Tires, Rims and Disc Wheels

Tire Infl

ation

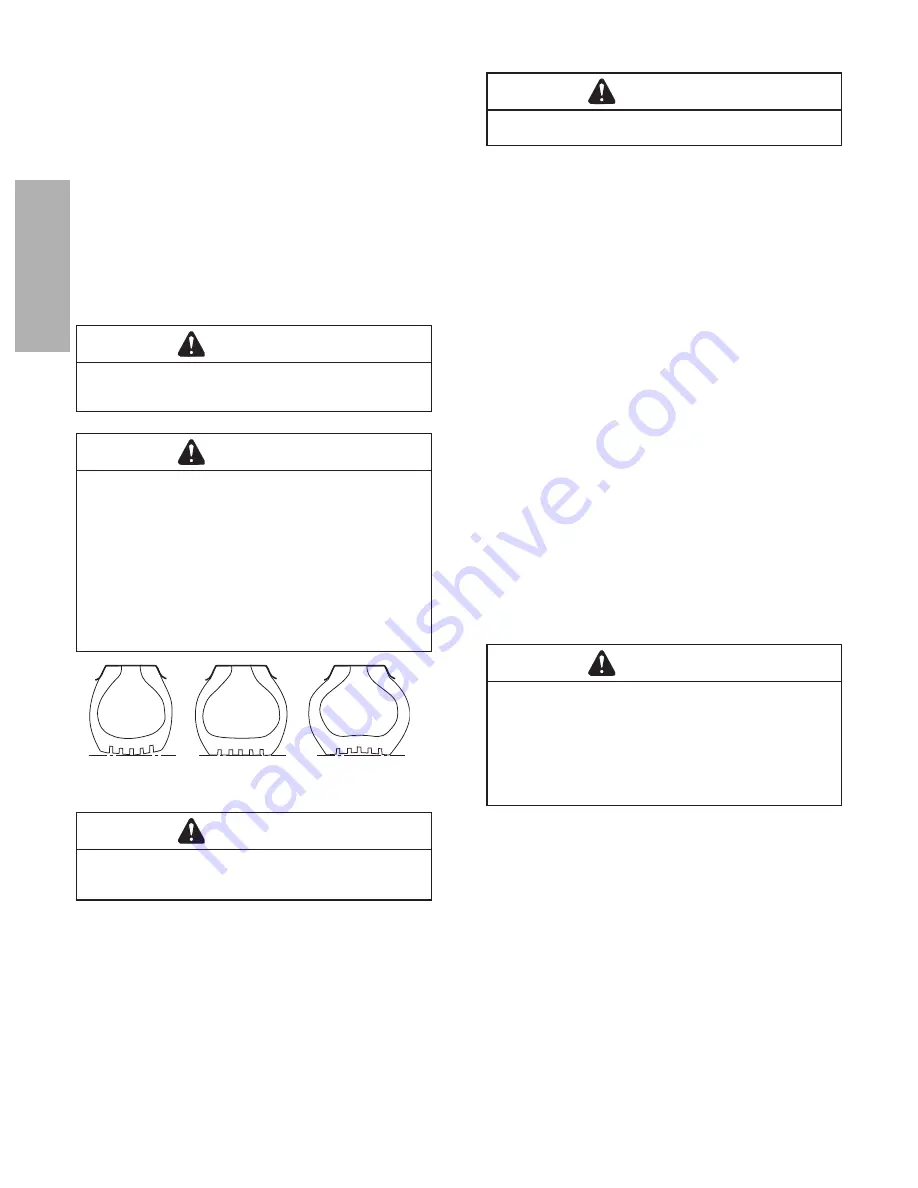

Proper and improper inflation will produce the tire

section and ground contact characteristics shown in

Figure 10

. Tire inflation must be checked daily while

tires are cold.

Either overinflation or underinflation will cause

premature tire wear.

CAUTION

Do not attempt to adjust the inflation pressure

while the tires are hot.

CAUTION

Do not exceed the cold inflation pressures. In

some cases the rim or disc wheel will have a

lower inflation pressure that the tire, in which

case the lower pressure must be used. The

maximum inflation pressure to be used is

shown on the certification label. Tire inflation

must be checked during road stops to locate

air losses. Also, remove any foreign objects

jammed between the dual wheels.

Figure 10. Proper Tire Inflation

WARNING

Repair any leaks immediately. All tires must be

equipped with valve caps.

Tire Overinflation

Overinflation weakens the cord body of the tire by

reducing its ability to absorb road shocks.

Overinflation can cause failure due to fatigue

cracks.

Overinflation can also cause rim and wheel

damage.

1. Inflate to correct pressure when tires are cool.

WARNING

Do not overinflate tires.

2. Never “bleed” tires to relieve excessive pressure

buildup when the tires are warm. Excessive buildup of

air pressure can be due to load, underinflation, speed, or

a combination of the three.

Tire Underinflation

Underinflation causes rapid wear and premature fail

-

ure. Underinflation or overloading of the tires on any

vehicle driven at sustained speeds will result in weaken-

ing of the tire cords. This can make the tire susceptible

to further damage or failure even under normal load and

inflation conditions.

Matching Dual Tires

Matching of the duals by size will result in longer tire

life. Improper matching will cause the larger diameter tire

to carry an overload. This will cause typical overloaded

tire difficulties. The smaller diameter tire will also wear

more rapidly due to scuffing. Differences of not more

than 1/4 inch (6.35 mm) in diameter or 3/4 inch (19.1

mm) in circumference are allowed.

NOTE: The smaller of the two tires should be mount-

ed in the inside position.

Removing Tire and Rim Assemblies

WARNING

Before removing the tire and rim or the tire and

disc wheel assemblies, remove the valve core

and exhaust all air from both tires in the dual

assembly. Check the valve stem by running a

piece of wire through the stem to make sure it is

not plugged.

Removing Tire and Disc Wheel Assemblies

With the trailer supported by jacks and blocks, remove

all the air from the tires (see warning on this page). Re-

move the cap nuts (see

Figures 14

and

15

). Remove the

outside tire and disc wheel. Remove the inside tire and

disc wheel if it must be changed.

OVER

INFLATION

PROPER

INFLATION

UNDER

INFLATION