26

RDT-07-0122

®

NORD

fire

|

FDMQ

www.etsnord.com

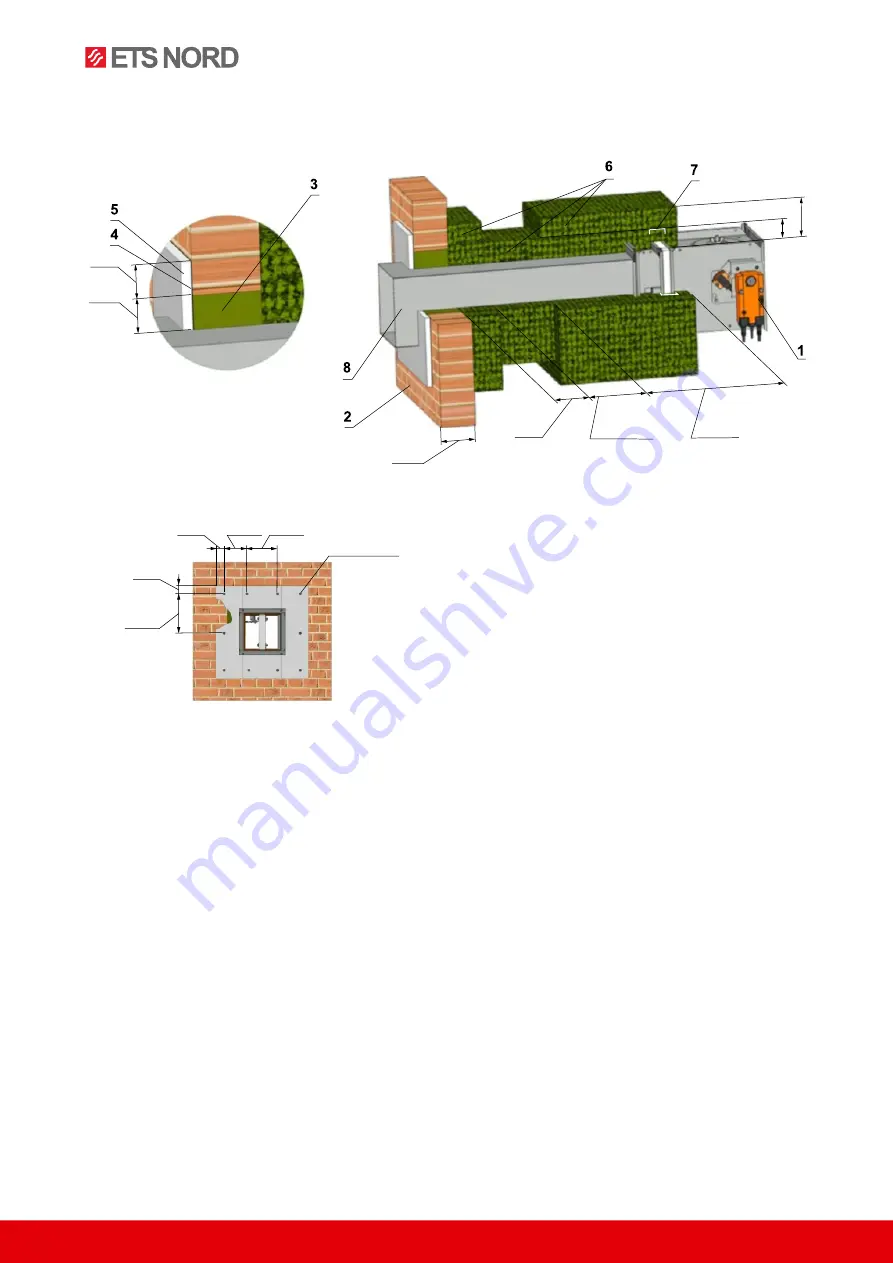

Fig. 28 Outside solid wall construction- mineral wool, stuffing box, fire protection mastic

and cement lime plate.

Position:

1 Fire damper

2 Solid wall construction

3 Stuffing box (mineral stone wool min. density 140 kg/m³)

4 Fire protection mastic min. thickness 1 mm

5 Cement lime plate min. thickness 15 mm

(min. density 870 kg/m³)

6 Stone wool with one side stitched wire fencing (min.

density 105 kg/m³), thickness 60 mm

7 Profil U25x40x25

** Stuffing box, fire protection mastic, cement lime plate and insulation materials can be replaced by

another approved fire sealing system for damper installation with equivalent material properties.

*** Depends on the distance of the flap from the construction, when the maximum distance from

the construct is not limited and according to EN 15882-2 must use the required number of

hinges according to EN 1366-1:2014.

**** Reinforcement fixing VRM see Fig. 81 Installation of profile U25x40x25 see Fig. 82

***** When using Rockwool Conlit Ductrock EIS 120, th. 60 mm, the overall fire resistance of the EIS 120

can be achieved.

T - thickness of the insulation (mm)

The duct at the point of penetration can be anchored to the fire wall construction!

Shown schemes of incorporation and damper are illustrative only!

38

Used materials - example:**

3

Promapyr, Rockwool Steprock HD, Hilti CFS-CT B 1S 140/50

4

Promastop - P, K, Hilti CFS-CT

5

Promatect - H

6

Rockwool Wired Mat 105 th. 60 mm

** Stuffing box, fire protection mastic, cement lime plate and

insulation materials can be replaced by another approved fire

sealing system for damper installation with equivalent material

properties.

*** Depends on the distance of the flap from the construction, when

the maximum distance from the construct is not limited and

according to EN 15882-2 must use the required number of

hinges according to EN 13366-1:2014.

**** Installation of profile U25x40x25 see Fig.79

Position:

1 Fire damper

2 Solid wall construction

3 Stuffing box (mineral stone wool min. density 140 kg/m³)

4 Fire protection mastic min. thickness 1 mm

5 Cement lime plate min. thickness 15 mm

(min. density 870 kg/m³)

6 Stone wool with one side stitched wire fencing (min.

density 105 kg/m³), thickness 60 mm

7 Profil U25x40x25 ****

8 Duct

≤ 75*

≥ 20*

≥ 100

60

12

0

≥ 100

≥ 400

≤ 300

≥ 25

(min. 4x50)

≤ 300

≥ 25

≤ 300

38

Used materials - example:**

3

Promapyr, Rockwool Steprock HD, Hilti CFS-CT B 1S 140/50

4

Promastop - P, K, Hilti CFS-CT

5

Promatect - H

6

Rockwool Wired Mat 105 th. 60 mm

** Stuffing box, fire protection mastic, cement lime plate and

insulation materials can be replaced by another approved fire

sealing system for damper installation with equivalent material

properties.

*** Depends on the distance of the flap from the construction, when

the maximum distance from the construct is not limited and

according to EN 15882-2 must use the required number of

hinges according to EN 13366-1:2014.

**** Installation of profile U25x40x25 see Fig.79

Position:

1 Fire damper

2 Solid wall construction

3 Stuffing box (mineral stone wool min. density 140 kg/m³)

4 Fire protection mastic min. thickness 1 mm

5 Cement lime plate min. thickness 15 mm

(min. density 870 kg/m³)

6 Stone wool with one side stitched wire fencing (min.

density 105 kg/m³), thickness 60 mm

7 Profil U25x40x25 ****

8 Duct

≤ 75*

≥ 20*

≥ 100

60

12

0

≥ 100

≥ 400

≤ 300

≥ 25

(min. 4x50)

≤ 300

≥ 25

≤ 300

EIS 90

Screws has to be fixed in wall/ceiling

construction.

(If it is needed use steel bracket).

* Around the perimeter

Screw