Operating instructions

Non-Contact Safety System CES-A-UBA-01/CES-A-UBA-01B

32

(Translation of the original operating instructions) 2097097-17-08/20

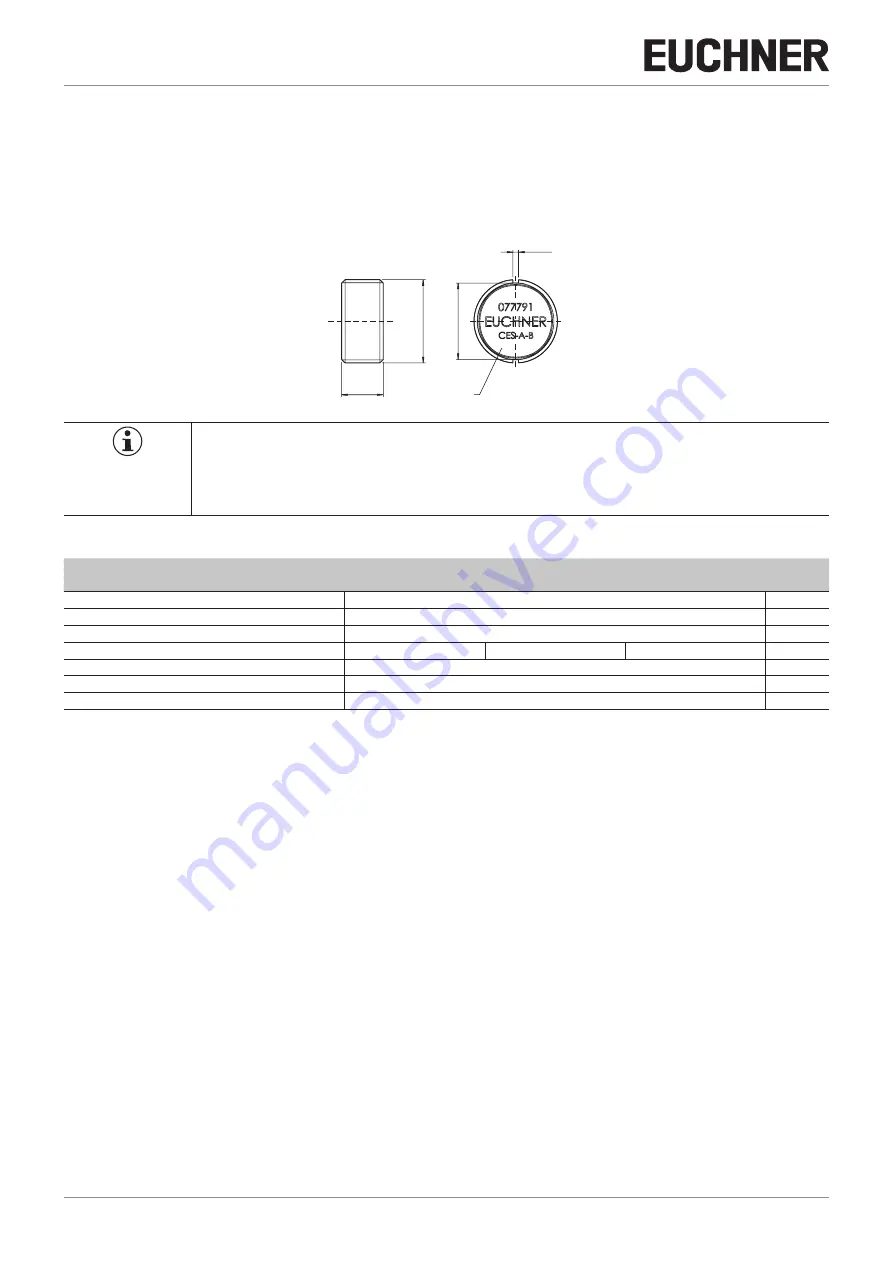

11.9. Actuator CES-A-BMB

Ì

Cylindrical design M12 x 75

Ì

In combination with read head CES-A-LMN-SC

(actuating range on request for read head CES-A-LNA…/LCA…)

Dimension drawing

11

0,80

6

M

12

x0

,7

5

Active face

NOTICE

Ì

The actuator can be screwed into the M12 x 0.75 thread provided with the aid of an insertion tool

(order no. 037 662).

Ì

Flush installation of the actuator in steel is permissible.

Technical data

Parameter

Value

Unit

min.

typ.

max.

Housing material

Stainless steel

Dimensions

M12 x 0.75, depth 6

mm

Weight

0.002

kg

Ambient temperature

-25

-

+85

°C

Degree of protection

IP67/IP69/IP69K

Installation orientation

Active face opposite read head

Power supply

Inductive via read head