29

2522722-01-05/19 (Translation of the original operating instructions)

Operating Instructions

Safety Relay with IO-Link ESM-CB

EN

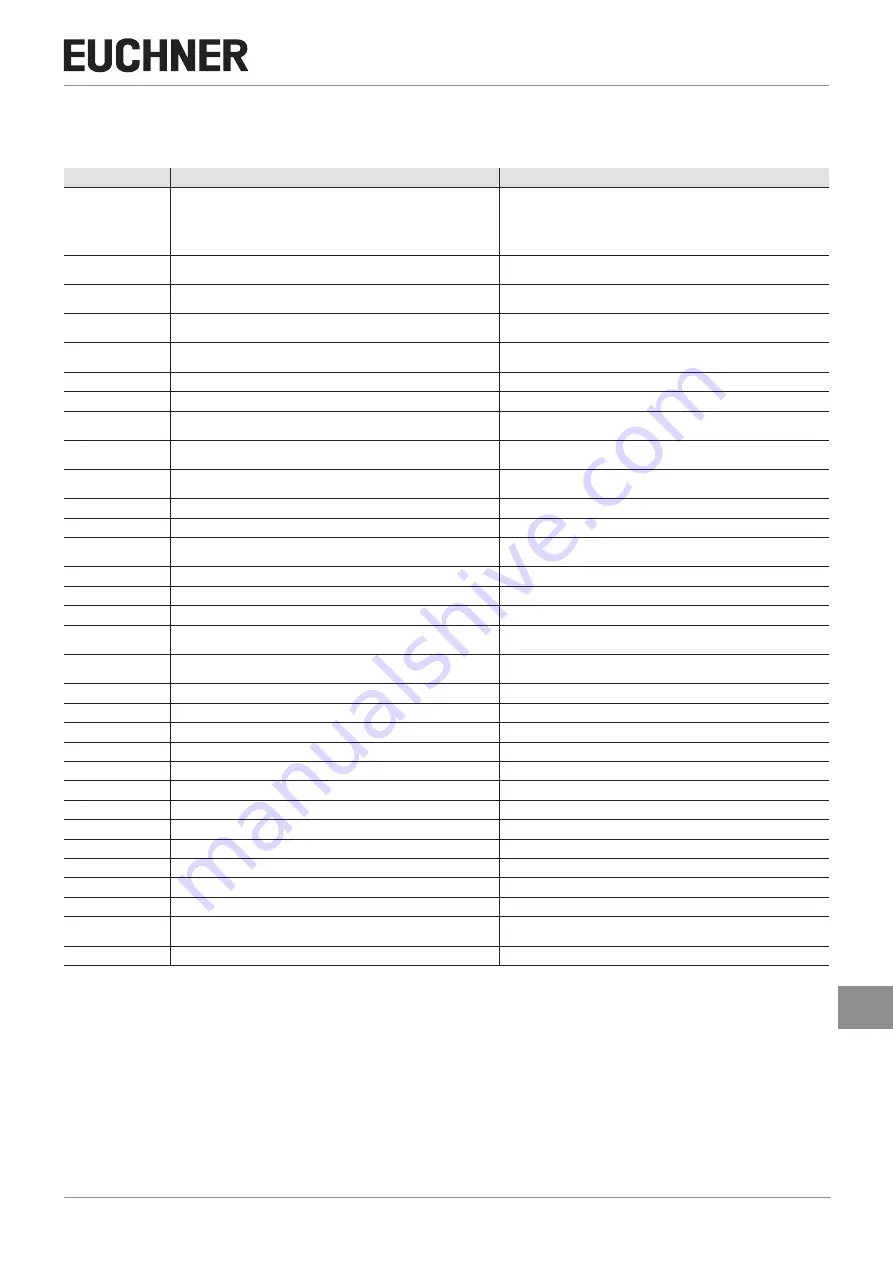

14.6. Error table for BR devices

Depending on the device type, not all error messages are required or supported.

Error number

Error designation

Cause/remedy

0x01+A4:E25

Internal error

All errors that prevent normal operation and over which the customer

has no control.

- Error in the program files

- Error in the light barrier

- Safe control of guard locking no longer possible

0x06

Internal error

Fault on the internal switching element. Guard locking can no longer be

controlled safely.

0x1F

Actuator not detected often enough during teach-in operation/actuator

removed.

See error designation

0x20

DIP switch configuration does not correspond to the software configu-

ration.

DIP switch configuration is not identical to the configuration saved in the

memory. The user must check the DIP switch setting.

0x21

DIP switch configuration between the channels not plausible.

DIP switch configuration for the two channels is not plausible or does not

match. The user must check the DIP switch setting.

0x25

Invalid actuator detected during teach-in operation.

Actuator detected is not a valid actuator or actuator is faulty.

0x2E

Different states of FI1A and FI1B

Different signal states at the two safety inputs.

0x2F

Communication error BR (master)

Diagnostics communication between master and slave not possible/

communication disrupted

0x31

Test pulse on FI1A not detected.

Missing test pulse

Examples: short circuits, FI1A and FI1B swapped.

0x32

Test pulse on FI1B not detected.

Missing test pulse

Examples: short circuits, FI1A and FI1B swapped.

0x36

Test pulse on FI1A not detected on PowerUp.

Missing test pulse

0x37

Test pulse on FI1B not detected on PowerUp.

Missing test pulse

0x43

Disabled actuator detected during teach-in operation.

Already taught in but disabled actuator has been detected. The user

must present the taught-in actuator or teach in another actuator.

0x44

Invalid actuator detected

0x4C

HIGH level on output FO1A even though LOW level is expected.

A HIGH level has been detected on safety output FO1A during PowerUp.

0x4D

HIGH level on output FO1B even though LOW level is expected.

A HIGH level has been detected on safety output FO1B during PowerUp.

0x4E

LOW level on output FO1A even though HIGH level is expected.

Although safety output FO1A has switched off, a HIGH level has been

read back.

0x4F

LOW level on output FO1B even though HIGH level is expected.

Although safety output FO1B has switched off, a HIGH level has been

read back.

0x50

Discrepancy time between FO1A and FO1B too long.

Switch-on/switch-off time between FO1A and FO1B too long.

0x51

Error on reading back the test pulse on FO1A.

Missing test pulse

0x52

Error on reading back the test pulse on FO1B.

Missing test pulse

0x54

General output error

0x60

Supply voltage too high.

Overvoltage

0x61

Supply voltage too low.

Low voltage

0x62

Temperature too high.

Temperature in housing too high.

0x63

Temperature too low.

Temperature in housing too low.

0x64

Guard locking supply voltage too high.

Overvoltage

0x65

Guard locking supply voltage too low.

Low voltage

0x67

Advance warning supply voltage too low 5%.

Low voltage

0x88

Plausibility error: bolt fracture

Transponder for the bolt has been detected without the door closed.

0x8A

Plausibility fault, signal sequence

Transponder has been detected without movement of the locking arm

(latch).

0x8B

Escape release

Escape release has been actuated (only if parametrized).