System Manual Safety System MGB-AR in Combination with a Locking Module

17

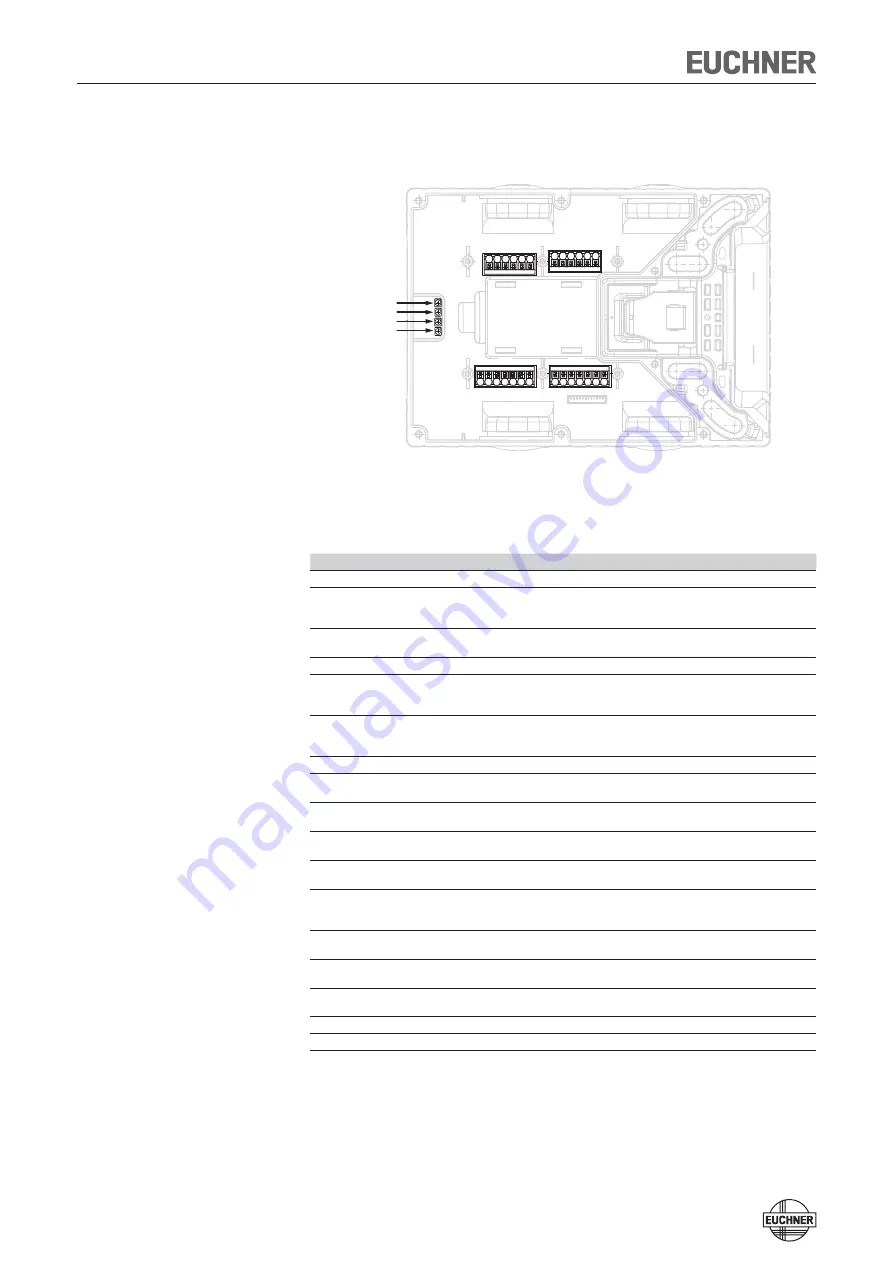

Pin assignment and contact description

Figure 16: Connections and LEDs

Terminal

Designation

Description

X.1 to X.

-

See the enclosed data sheet

X.4

U

A

Power supply for the interlocking solenoid and the monitoring out-

puts, DC 4 V, must be present continuously so that the interlocking

solenoid functions.

X.5 and X.6

0V

M

Ground for the power supply to the interlocking solenoid, DC 0 V (con-

nected internally to X5.5).

X.7

U

CM

Control voltage for switching on and off the guard locking, DC 4 V.

X4.1

I

A

Enable input for channel A, connect to DC 4 V in separate opera-

tion. In case of switch chains, connect output signal O

A

from previous

device.

X4.

I

B

Enable input for channel B, connect to DC 4 V in separate opera-

tion. In case of switch chains, connect output signal O

B

from previous

device.

X4.

-

Not used

X4.4

O

A

Safety output channel A,

ON when door is closed and guard locked.

X4.5

O

B

Safety output channel B,

ON when door is closed and guard locked.

X4.6

RST

Reset input, device is reset if DC 4 V are applied to RST for at least

s.

X5.1

O1

Door monitoring output,

ON when the door is closed.

X5.

O

Bolt tongue monitoring output,

ON when the door is closed and the bolt tongue is inserted in the

locking module.

X5.

O

Guard locking monitoring output,

ON when the door is closed and guard locked.

X5.4

O4

Monitoring output DIA,

ON when the device is in the fault state.

X5.5

0V

Ground for power supply, DC 0 V

(connected internally to X.5 and X.6).

X5.6

U

B

Power supply, DC 4 V

X.1 to X.7

-

See the enclosed data sheet

Table 1: Pin assignment and contact description

4

2

6

3

5

1

1

1

4

2

6

3

5

1

2

3

4

5

X3

X4

X5

X2

LED

DIA 1

Power

DIA 2

State

gn

gn

rd

ye

7 6

2

3

4

5

7 6