13

2123622-04-06/19 (translation of the original operating instructions)

Operating Instructions Safety Systems

MGB-L..B-PN.-… (PROFINET) and With Expanded Data Structure Type C

EN

7.8.

Lockout mechanism

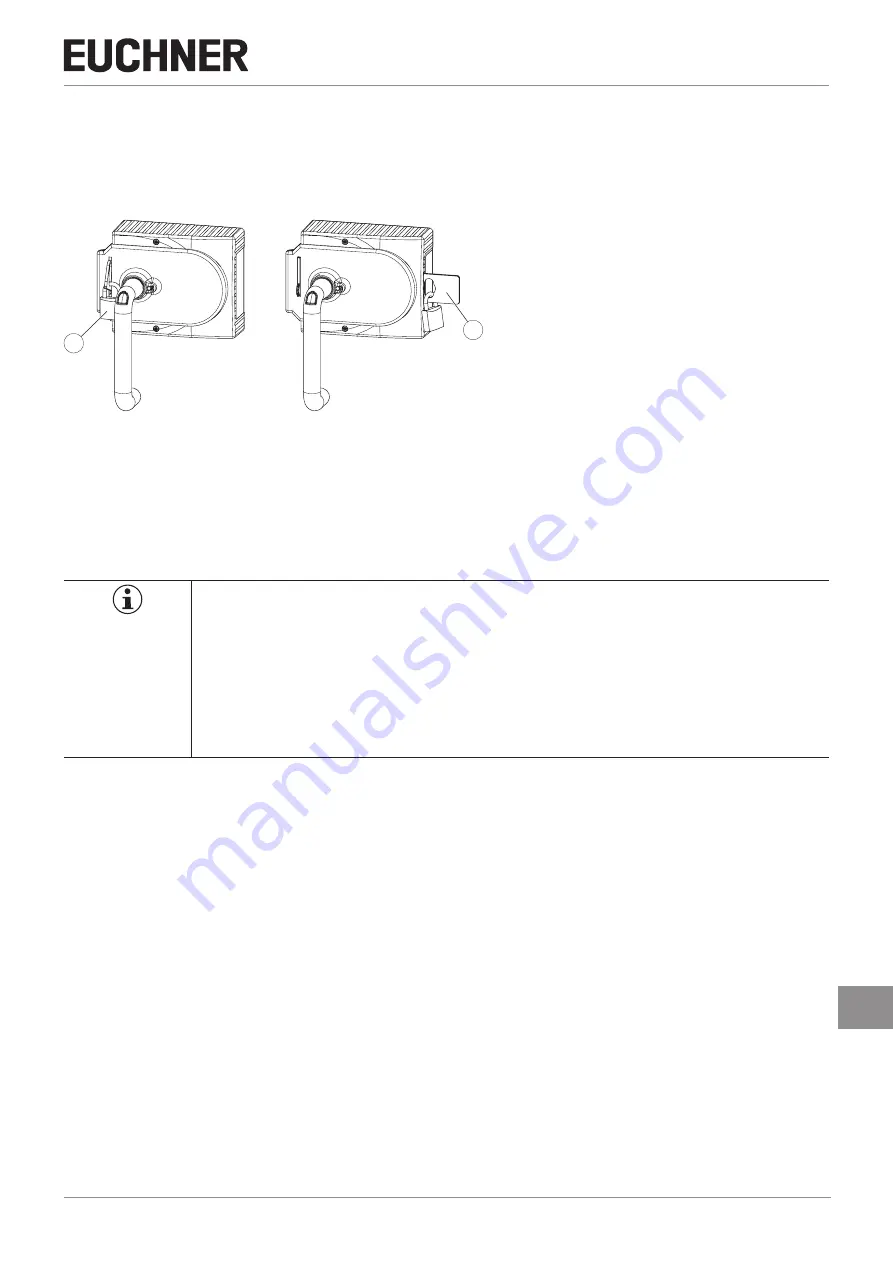

If the lockout mechanism is pivoted out/extended, the bolt tongue cannot be extended. The lockout mechanism can be

¨

To pivot out, press the grooved part (only possible with bolt tongue retracted).

1

2

Key

:

1

Padlock

∅

min. 2 mm,

∅

max. 10 mm

Notice:

You can fit a maximum of 3 locks Ø 8 mm

.

2

Automatically extending, second lockout mechanism

Padlock

∅

min. 6 mm,

∅

max. 10 mm

Figure 7:

Lockout mechanism secured with padlock

7.9.

Escape release (optional)

The escape release is used to open a locked safety guard from the inside without tools.

The system enters into a latching fault when the escape release is actuated.

15. System status table on page 38

,

signal sequence incorrect

status (DIA red, Lock flashes 1 time).

The system might not enter into a latching fault if the escape release is actuated very slowly.

Important!

Ì

It must be possible to operate the escape release manually from inside the protected area without

tools.

Ì

It must not be possible to reach the escape release from the outside.

Ì

The actuator must not be under tensile stress during manual release.

Ì

The escape release meets the requirements of Category B according to EN ISO 13849-1:2008.

Ì

The correct function must be checked at regular intervals.

Ì

Please observe the notes on possibly enclosed data sheets.

Ì

Fit escape release such that operation, inspection and service are possible.

Ì

The actuation axis for the escape release must be inserted min. 10 mm into the handle module. Note the information on

the different profile widths in the next chapter.

Ì

Align escape release axis at right angles to the handle module. See