21

112657-12-01/15 (translation of the original operating instructions)

Operating Instructions Safety Systems

MGB-L0…-AR.-… and MGB-L0…-AP.-…

EN

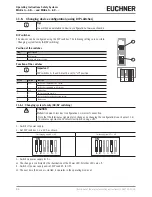

11. Electrical connection

WARNING

In case of an error, loss of the safety function through incorrect connection.

Ì

To ensure safety, both safety outputs (FO1A and FO1B) must always be evaluated.

Ì

The monitoring outputs must not be used as safety outputs.

Ì

Lay the connection cables with protection to prevent the risk of short circuits.

CAUTION

Risk of damage to equipment or malfunctions as a result of incorrect connection.

Ì

The inputs on an evaluation unit connected must be positive-switching, as the two outputs on the

safety switch deliver a level of +24 V in the switched-on state.

Ì

All the electrical connections must either be isolated from the mains supply by a safety trans-

former according EN IEC 61558-2-6 with limited output voltage in the event of a fault, or by other

equivalent isolation measures.

Ì

All electrical outputs must have an adequate protective circuit for inductive loads. The outputs

must be protected with a free-wheeling diode for this purpose. RC interference suppression units

must not be used.

Ì

Power devices which are a powerful source of interference must be installed in a separate location

away from the input and output circuits for signal processing. The cable routing for safety circuits

should be as far away as possible from the cables of the power circuits.

Ì

To prevent EMC problems, it is imperative you follow the chapter

11.5. Notes on cable laying on

page 23

. Follow EMC notes on devices in the immediate vicinity of the MGB system and their

cables.

Ì

In order to avoid EMC interference, the physical environmental and operating conditions at the

installation site of the device must comply with the requirements according to the standard

DIN EN 60204-1:2006, section 4.4.2/EMC.

Important!

Ì

If the device does not appear to function when the operating voltage is applied (e.g. green Power

LED does not illuminate), the safety switch must be returned to the manufacturer.

Ì

To ensure the stated degree of protection is achieved, the cover screws must be tightened to a

tightening torque of 1 Nm.

Ì

Tighten screw for the cover for the mechanical release to 0.5 Nm.