SD20-G Series

150

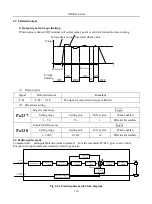

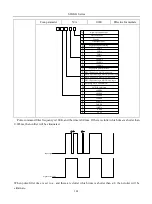

c) Internal position sequence diagram

Once any preset position is selected by input contacts SD0~SD2 then require a trigger signal from the input

contact CTRG, enabled trigger signal to start operation.

Diagram below shows an example for absolute move.

Setting range

Setting unit

Mfr’s value

When enabled

0~32000

ms

0

Effective Immediate

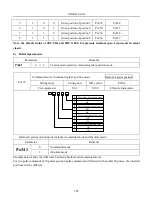

Po367

Interval time 2

Internal register position

Setting range

Setting unit

Mfr’s value

When enabled

0~32000

ms

0

Effective Immediate

Po368

Interval time 3

Internal register position

Setting range

Setting unit

Mfr’s value

When enabled

0~32000

ms

0

Effective Immediate

Po369

Interval time 4

Internal register position

Setting range

Setting unit

Mfr’s value

When enabled

0~32000

ms

0

Effective Immediate

Po370

Interval time 5

Internal register position

Setting range

Setting unit

Mfr’s value

When enabled

0~32000

ms

0

Effective Immediate

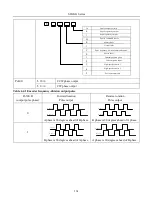

Po371

Interval time 6

Internal register position

Setting range

Setting unit

Mfr’s value

When enabled

0~32000

ms

0

Effective Immediate

Po372

Interval time 7

Internal register position

Setting range

Setting unit

Mfr’s value

When enabled

0~32000

ms

0

Effective Immediate

Po373

Interval time 8

Internal register position

Setting range

Setting unit

Mfr’s value

When enabled

0~32000

ms

0

Effective Immediate

Summary of Contents for SD20-G Series

Page 35: ...SD20 G Series 35 M3 structure Fig 3 1 5 Servo drive structure 3...

Page 36: ...SD20 G Series 36 ML3 structure 118 5 5 7 5 93 297 8 223 118 93 0 5 12 5 7 5 4 M4...

Page 38: ...SD20 G Series 38 M4 structure Approx mass 10 365 kg Fig 3 1 7 Servo drive structure 5...

Page 39: ...SD20 G Series 39 M5 structure Approx msaa 11 1Kg Fig 3 1 8 Servo drive structure 6...

Page 40: ...SD20 G Series 40 M6 structure Approx mass 17 4Kg Fig 3 1 9 Servo drive structure 7...

Page 182: ...SD20 G Series 182 Fig 6 4 44SD20E Cam internal frameworkdiagram...