SD20-G Series

42

3.2.3 Precautions on servo motor installation

Item

Description

Anticorrosive

Before starting installation, thoroughly remove the anticorrosive paint that coats the end of

motor shaft.

Alignment

Align the shaft of the servo motor with the shaft of the equipment, and then couple the shafts.

Orientation

Servo motor can be installed either horizontally or vertically.

Handing oil and

water

If the servo motor is used in a location that is subject to water drops, make sure of servo motro

protective specifications.

If the servo motor is used in a location that is subject to water or oil mist, use a servo motor

with oil seal.

Precautions on using servo motor with oil seal

·The oil surface must be under the oil seal lip.

·Use an oil seal in favorably lubricated condition.

·When servo motor is installed vertically, be sure that oil will not stay in the oil seal lips.

Cable stress

Make sure there are no bends or tension on the power cables.

Be especially carefully to wire signal cables so that they are not subject to stress because the

core wires are very thin at only 0.2 to 0.3mm.

Connectors

Observe the following precautions:

·Make sure there is no foreign matters such as dust and metal chips in the connector before

connecting.

·when the connectors are connected to the motor, be sure to connect the end of servo motor

circuit cables before connecting the encoder cable’s end. If the encoder cable’s is connected,

the encoder may be damaged because of the voltage differences between PE.

·Make sure of the pin arrangement.

·Do not apply shock to resin connectors. Otherwise, they may be damaged.

·When handling a servo motor with its cable connected, be sure not to apply stress on the

connector. The connector may be damaged by stress.

Summary of Contents for SD20-G Series

Page 35: ...SD20 G Series 35 M3 structure Fig 3 1 5 Servo drive structure 3...

Page 36: ...SD20 G Series 36 ML3 structure 118 5 5 7 5 93 297 8 223 118 93 0 5 12 5 7 5 4 M4...

Page 38: ...SD20 G Series 38 M4 structure Approx mass 10 365 kg Fig 3 1 7 Servo drive structure 5...

Page 39: ...SD20 G Series 39 M5 structure Approx msaa 11 1Kg Fig 3 1 8 Servo drive structure 6...

Page 40: ...SD20 G Series 40 M6 structure Approx mass 17 4Kg Fig 3 1 9 Servo drive structure 7...

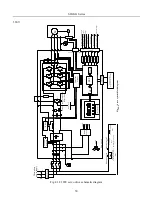

Page 182: ...SD20 G Series 182 Fig 6 4 44SD20E Cam internal frameworkdiagram...