22

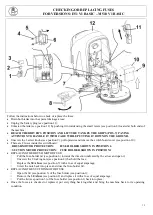

Put the potentiometer for speed adjustment into min. position by pressing it towards the drawing

of the turtle, on the label.

Push the brush switch to activate the brush. The brush does not rotate when the green light is on.

Slowly push forward the drive control and release it as soon as the brush starts rotating. The brush motor will rotate for

2 seconds thus allowing for the brush release. Repeat the same operation again if necessary.

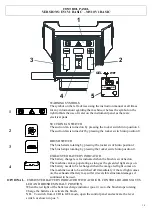

Follow the instructions below

to release

the brush or disc pad holder with abrasive disc:

Press the brush button to deactivate the brush function.

Lift the brush plate with pedal (pos. 1).

Press the brush release button on the keyboard.

The releasing sequence will be activated and the brushes will be released from the plate.

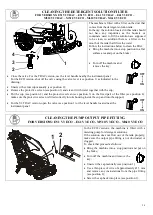

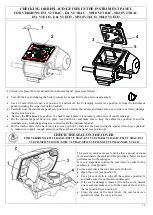

FILLING THE DETERGENT SOLUTION TANK

FOR VERSIONS: E51 V1 BASIC-E51 V2 TRAC-E51 V3 ECO–

E61 V2 TRAC- E61 V3 ECO-

M510 V1 BASIC-M510 V2 TRAC-M510 V3 ECO-M610 V2 TRAC-M610 V3 ECO

The tank should be filled using clean water mixed with an appropriate detergent solution suited for the type of floor and

for the dirty conditions of the floor and using a product suitable for cutting down foam.

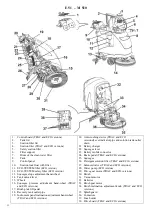

1

2

3

4

Use the mouth of the tank (see position 3) to fill the solution tank.

For TRAC and ECO versions, there is a filter (see position 2) located inside the mouth of the tank (see position 3), which

should only be removed if the opening is clogged or obstructed.

Use either a rubber hose (see position 1) connected to the water distribution system or a clean bucket (see position 3) and

pour water into the tank.

Make sure the water used to fill the tank does not exceed 40°C.

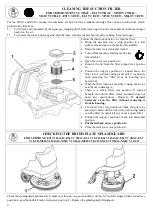

Look at the instructions on the package to determine how much detergent solution to use, how to mix the solution and

what safety precautions to take before using the product.

Make sure to use low-foaming liquid detergents or appropriate products to cut-down foam.

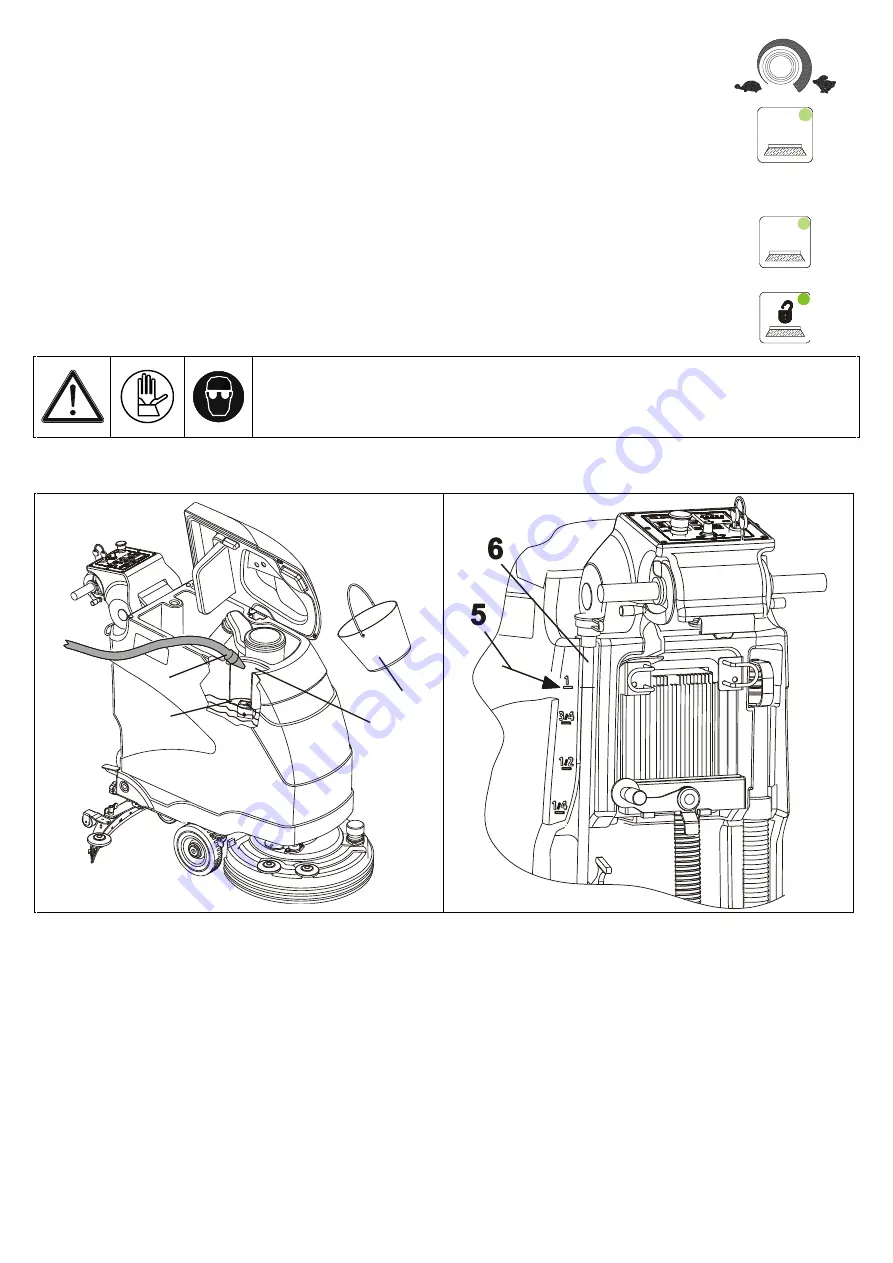

Fill up the tank only to the level indicated by the filter (see position 2)

without exceeding

notch 1 (see position 5), which

is located in the rear part.

The tank level can be viewed through the clear pipe (see position 6).

In order for the machine to work properly, it is advisable not to exceed notch 1.

WARNING: DO NOT POUR INFLAMMABLE LIQUIDS INTO THE TANK.