Summary of Contents for MAGNUM 901 EB EVOLUTION

Page 2: ......

Page 13: ...13 ...

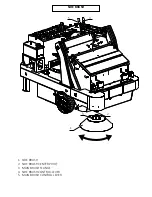

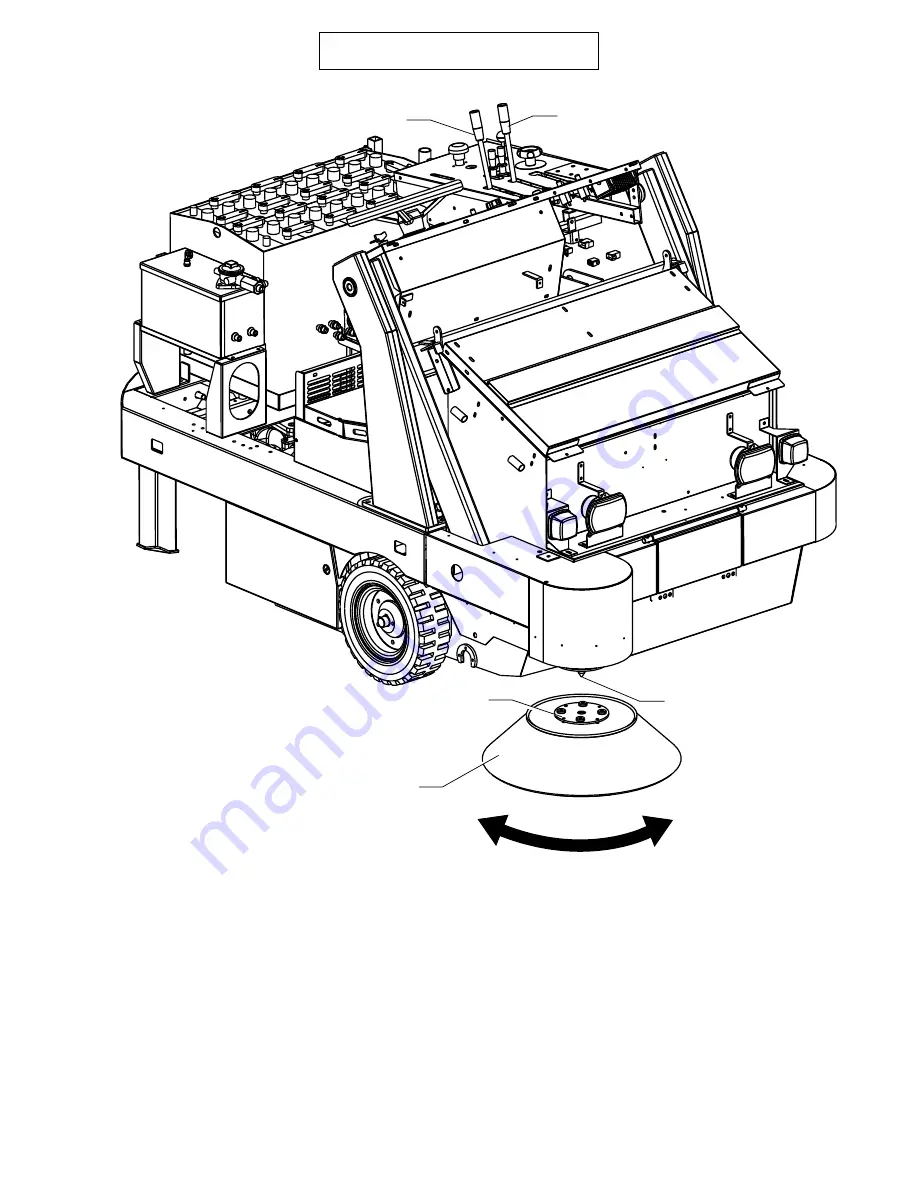

Page 14: ...MACHINE DESCRIPTION 1 3 2 4 8 9 10 16 15 14 13 12 11 7 25 20 19 21 22 23 17 18 24 26 5 6 ...

Page 35: ...TECHNICAL DIMENSION DRAWINGS 35 ...

Page 38: ...HYDRAULIC SCHEME ...

Page 40: ...HYDRAULIC SCHEME ...

Page 58: ...58 ...

Page 62: ......