79

1

°

MAGNUM 901 HDK SWEEPER SERVICING AND

MAINTENANCE SCHEDULED SERVICING

AFTER 50

HOURS

DATE

DAY

MONTH

YEAR

EFFECTIVE NO

OF HOURS

Before starting the work have a close look at the machine if it has any leaking of: oil, fuel,

cooling liquid. Then open the hood and check the same things on the engine.

KUBOTA ENGINE D902:

Change the motor oil SAE 10 W 40 quantity 3.7 lt.

Change the filter oil p/n. 590010

Change of fuel filters cartridge p/n. 520011

Control and eventual replacement of fuel pre-filter p/n. 520036

Clearing of primary air filter cartridge p/n. 580206

Cleaning of secondary (security) cartridge p/n. 580207

Rotation control of VORTEX pre-filter fan

Control of fan belt tension

Control of fuel tubes and clamp bands

Control of radiator liquid level

Control that the radiator is not obstructed, eventually clean

Control the good state of the engine air aspiration tubes (in-between air filter and engine)

MACHINE:

Check the battery liquid level

Check the state of the brush

Check dust seal gasket, flaps

Check gasket on hopper

Check the dust filter efficiency

Check the hydraulic system piping

Check the functioning of all the instruments and control levers

Check the good functioning of the braking system

Check the hydraulic oil level

Clean the hydraulic oil heat exchanger

Check the machine in all its functions

THE SCHEDULED SERVICING WAS CARRIED OUT BY:

NAME:_______________________________________________

SURNAME:___________________________________________

SIGNATURE:______________________________________________

_

SEAL OR STAMP OF THE DEALER

CARRYING

OUT

THE

SCHEDULED

SERVICING

NOTE:

Summary of Contents for MAGNUM HDK

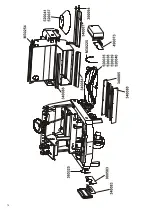

Page 12: ...13 FIG C...

Page 37: ...38 TECHNICAL DIMENSION DRAWINGS...

Page 38: ...39 TECHNICAL DIMENSION DRAWINGS...

Page 39: ...40 TECHNICAL DIMENSION DRAWINGS...

Page 43: ...44...

Page 46: ...47...

Page 48: ...49...

Page 50: ...51 9 1 1 6 8...

Page 52: ...53...

Page 54: ...55...

Page 56: ...57...

Page 58: ...59 91151...

Page 60: ...61...

Page 62: ...63...

Page 64: ...65...

Page 66: ...67...

Page 68: ...69...

Page 70: ...71...

Page 72: ...73...

Page 77: ...78...