Overload

The motor of your right angle grinding machine may be damaged when overloaded. This results from

excessive working pressure over a prolonged period. Therefore you should not try to accelerate your

working speed by increasing pressure on your machine. The abrasive disks work more efficiently if

only slight pressure is exerted on the grinding machine, thus avoiding a drop in the grinding speed.

Maintenance

• The protective cover, air slits and motor housing should be kept as free of dirt and dust as possible.

• Rub off the device with a clean cloth or use compressed air at a low pressure to blow out any dust

or dirt. Excessive amounts of metal dust may result in electricity from the internal components

being conducted on to exposed metal parts!

• Do not subject the grinding machine to any overload! Overloading will lead to a reduction in the

speed and performance and cause the machine to overheat! If this should happen, switch the

grinding machine off and let it cool down for approximately 30 minutes or to room temperature!

NOTE:

Turning off the grinding machine while it is being subjected to a load will reduce the working

life of the operating switch!

Cleaning and Care

• Before cleaning the machine, remove the mains plug from the socket and release the switch trigger

(1) to power off the tool

• For cleaning purposes, only use a slightly damp but not wet cloth!

• Do not use any abrasive additives (petrol, turpentine etc) as these may damage the plastic housing!

• A mild soap is suitable for cleaning the machine!

• Ensure that no moisture is allowed to get inside the machine!

• After cleaning, wipe the machine with a dry cloth!

EC Conformity Declaration

We hereby declare that the angle grinder AGR.1400 fulfils the requirements of directive: 2006/42/EC,

2006/95/EC, 2004/108/EC

This appliance conforms to the CE directives for radio interference suppression and low voltage

safety and has been built to meet current safety requirements. Subject to technical changes without

prior notice!

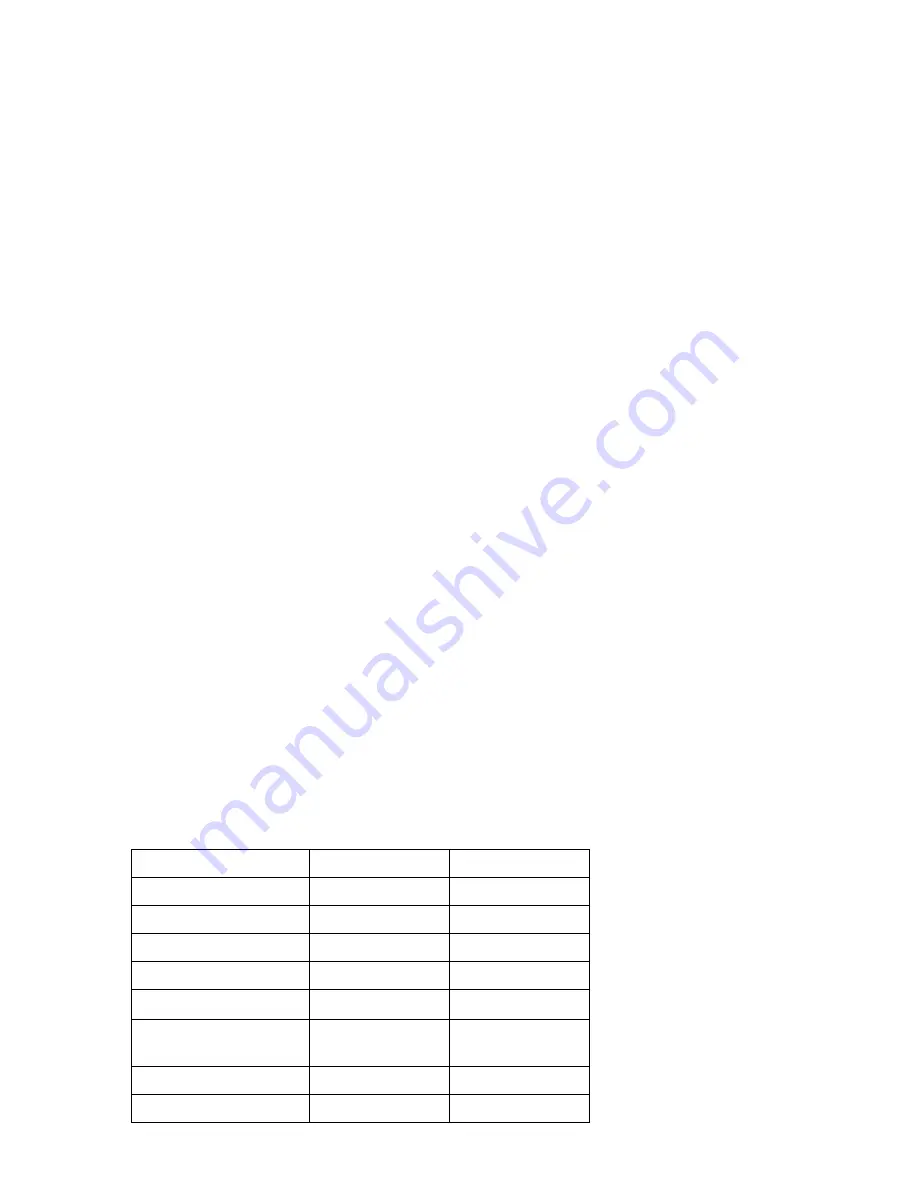

Technical Data

Model

AGR.2200/180

AGR.2200/230

Rated input

230V~50Hz

230V~50Hz

Rated power

2200W

2200W

No load speed

8000/min

6000/min

Disc size:

180mm

230mm

Class of tool

回

回

Sound pressure

level(Lpa)

dB(A) K=3 dB(A)

dB(A) K=3 dB(A)

Sound power level(Lwa)

dB(A) K=3 dB(A)

dB(A) K=3 dB(A)

Vibration

m/s

2

K=1.5 m/s

2

m/s

2

K=1.5 m/s

2