ISSUE 1/Original version/OCT 2013

12

12

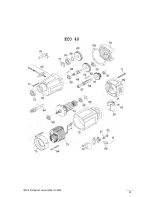

INSERTING AND REMOVING AN ACCESSORY (FIG. 1)

The tool holder accepts annular cutters with a 19,05 mm Weldon shank with one or more flats.

WARNING:

The teeth of a cutter are very sharp and can be dangerous.

1.

In order to fit an annual cutter it is necessary to remove the guard (1);

2.

Slide the pilot pin through the hole in the center of the cutter shank.

3.

Insert the shank of the accessory as far into the tool holder as possible.

4.

Tighten the two Allen screws with Allen key;

5.

To remove the accessory, loosen the Allen screws and take out the cutter.

PRIOR TO OPERATION

Try a few simple projects using scrap material until you develop a “feel” for the machine.

OPERATION

Instructions for Use

WARNING:

Always observe the safety instructions and applicable regulations.

WARNING:

To reduce the risk of serious personal injury, turn tool off and disconnect tool from

power source before making any adjustments or removing/installing attachments or

accessories.

MAGNETIC BASE

Material of minimum 10 mm thickness is required for the magnet to work the best.

The attachment force generated by the magnet depends on various factors.

•

Thickness of the material the magnet is placed on;

•

Paint or coating of the material the magnet is placed on;

•

Metal chips, oil or other dirt under the magnet.

If the LED indicator (see page 13) lights up GREEN, the magnet is generating sufficient attachment

force. If the LED indicator lights up RED, the magnet may not generating sufficient attachment force.

WARNING:

Do not use this machine when LED indicator is RED. Magnet is may not generate

sufficient attachment force

We would like to point out that this is only an indication and not a certainly that the magnet will

not release from the material. Euroboor accepts no liability ensuring from the magnet indicator not

functioning or functioning poorly.

Make sure that the magnet attaches tightly to the work piece before turning on the motor unit of the

magnetic drilling machine. Euroboor magnets have 2 coils; make sure that both coils are in contact

with the material. Do not connect any other machines to the electrical outlet the magnetic drilling

machine is plugged into, as it may result in the loss of magnetic force.

Always use the safety chain included. Drilling above your head is extremely dangerous and is not

recommended. For the use of magnetic drilling machines on pipes, not-flat or non-magnetic

materials, we refer to our brochure or our website www.euroboor.com where several vacuum

tightening systems and pipe clamping systems are mentioned.