ISSUE 1/Original version/OCT 2013

20

20

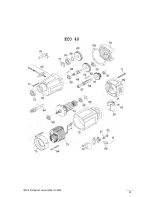

SPARE PART LIST AND EXPLODED VIEW of ECO.40/2

Nr.:

Article:

Description

Nr.: Article:

Description

1

020.0056

Frame

2

020.0106

Screw SSM6x16

3

020.0111

Washer M6

4

020.0096

Setting Nut

5

020.0091

Setting Screw

020.0098

Setting set (6x No. 4+5)

6

020.0052

Magneet

7

020.0201

Sensor

8

040.0011

Slide

9

032.0016

Rack

10

020.0156

Screw SSM6x20

11

032.0026

Motorholder

12

020.0146

Screw SSM6x25

13

040.0041

Top fixing plate 110mm

14

020.0142

Steady

15

020.0116

Spindle

16

020.0121

Springset spindle

17

020.0131

Circlip

18

020.0145

Autocoolant Ring

19

020.0136

Fixing Screw M8x8

20

020.0086

Brass rail set (stick)

21

020.0084/4

Pressing Strip 4 holes

22

020.0061

Capstan Hub assembly

23

020.0077

End Plate

24

020.0081

End Screw

25

020.0066

Arm for Capstan

26

020.0046

Motorcable

27

020.0041

Coupling nut motorcable

28

020.0031

Coupling nut maincable

29

020.0036

Main Cable

30

020.0182

Screw+nut

31

PP.RSEU

Rear plate

32

020.0101

Panel screw

33

PP.40EU

Front plate

34

020.0206

Sensor LED + cable

35

020.0006

On/Off switch

36

020.0016

Fuse Holder

37

020.0017

Fuse F2A

38

020.0011

Magnet Switch

39

020.0001

Control Unit 220v

39

020.0002

Control Unit 110v

40

020.0037

Cableclamp

41

040.0101

Motorunit 220v

040.0102

Motorunit 110v

51

032.0136

Screw for spring

52

032.0141

Spring

53

032.0116

Screw BK4,2x13

54

032.0156

Screw BK3,9x60

55

032.0121

Adaptor ring 22x0,5

56

040.0181

Adaptor ring 24x0,2

57

040.0161

Needle Bearing

58

032.0126

Bearing 8x22x7 (closed)

59

032.0221

Bearing 8x22x7

60

032.0171

Bearing 12x28x8

61

040.0171

Gear 34/28

62

040.0251

First Gear

63

040.0176

Spindle Gear

64

040.0191

Spindle drive shaft

65

040.0231

Gear shaft

66

040.0246

Axle

67

032.0131

Adaptor ring cap

68

032.0146

Carbon brush set

69

032.0111

End cover

70

032.0241

Housing

71

032.0106

Screw BK4,8x50

72

040.0196

Bearing 15x35x11

73

032.0161

Baffle

74

040.0266

Armature 220v

040.0267

Armature 110v

75

040.0276

Field 220v

040.0277

Field 110v

76

040.0241

Gear casing

77

032.0166

Circlip 472/28/1,2

78

040.0146

Inner gear plate

78.1 032.0237

Gasket

79

040.0301

Key

80

032.0211

Casing pin

81

040.0291

Clutch shaft

82

040.0286

Gear switch

83

032.0171

Bearing 12x28x8