Instruction Manual ZHK

V07-19.0

101/129

and treatment of the corresponding sites are generally not required. Depending on the material

used, a superficial oxidation can be removed as part of regular maintenance and the appropriate

site treated with suitable protective measures.

Before servicing any electrical parts such as fan motors, damper motors, electric

heater etc. use the emergency-stop control devices, to separate the parts com-

pletely from the power supply. Indications of

chapter 2 (Safety instructions)

have to be observed!

Please note that we are not responsible for damage caused by improper handling of solvents and

cleaning agents, and we would not be liable for mechanical damage. Solvents and cleaning agents

may not contain alcohol for use on coated surfaces.

In order to avoid corrosion, in the case of components made of stainless steel like drain pans or

bases, ensure that fragments of carbon steel laying around are removed and stainless steel parts

are cleaned from swarf of carbon steel.

To order spare parts please contact your EUROCLIMA sales partner.

EUROCLIMA recommends, depending on the specified AHU execution, performing checks,

maintenance and repair work in compliance to the specifications according to VDI 6022 sheet 1,

requirements regarding operation and maintenance.

9.1

Electrical connection, control cabinet

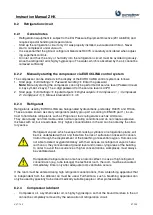

All electrical connections must be inspected annually and deficiencies (e.g. loose cable strands,

loose screw and clamp connection etc.) must be identified and eliminated immediately.

The following maintenance work is recommended for the control cabinet of AHUs with integrated

control:

-

annual change of the filter

-

annually check the function of the fan for the control cabinet ventilation (if present)

-

annually check the function of the heater (installed in outdoor AHUs)

-

annually check of screw connections and electrical connections and if necessary retighten

-

cleaning of possible dust deposits

9.2

Fan / motor group

9.2.1

Fan

-

Check for dirt, debris, damage and corrosion, clean if necessary.

-

Coat surface damage of the housing and impeller with zinc dust paint.

-

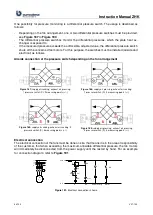

Flexible connections are to be checked for damage through visual inspection.

-

Check vibration isolators for proper mounting through damage (visual inspection).

-

Check the protection grid (Fan in and/or outlet) if available for correct installation / damaged

(visual inspection).

-

Check the drain (if available) for functionality.

-

Test the wheel by rotating it by hand for abnormal noises.

-

Rotate the wheel by hand and check for strange bearing noise.

-

Renew both bearings if there are irregular or rough noises.

-

The theoretical lifetime, depending on the operating conditions, is at least 20,000 hours.

Summary of Contents for ZHK Series

Page 1: ...ZHK INSTRUCTION MANUAL ...