Instruction Manual ZHK

V07-19.0

103/129

9.2.2

Motor

-

Check the motor for cleanliness and clean if necessary.

-

Measure current consumption, which must not exceed the rated current indicated on the name-

plate.

Motor bearings

-

In case of irregular or unusual sounds, the corresponding bearing must be replaced.

-

Small and medium sized motors are equipped with closed bearing, running for several years

without the need of lubrication.

-

Bearings of larger motors, depending on the motor manufacturer and motor size, are equipped

with nipples for lubrication. For exact details and information regarding grease type and quan-

tity for lubrication, please refer to operating instructions of the motor manufacturer. After three

re-lubrications, the bearings must be dismounted, cleaned and greased again. For lubrication

intervals under normal operating conditions and 24 h/day load refer to

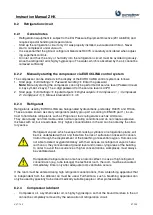

Size

2-pole

3000 1/min

4-pole

1500 1/min

6-pole

1000 1/min

8-pole

750 1/min

bis 180

12

12

12

12

bis 250

6

12

12

12

280

3

12

12

12

Table 15:

Lubrication intervals for motor bearings (in month)

-

For different, unfavorable operating conditions, the intervals are to be reduced according to the

motor manufacturer's instructions.

-

Recommended grease types for the relubrication of motor bearings can be taken from

9.2.3

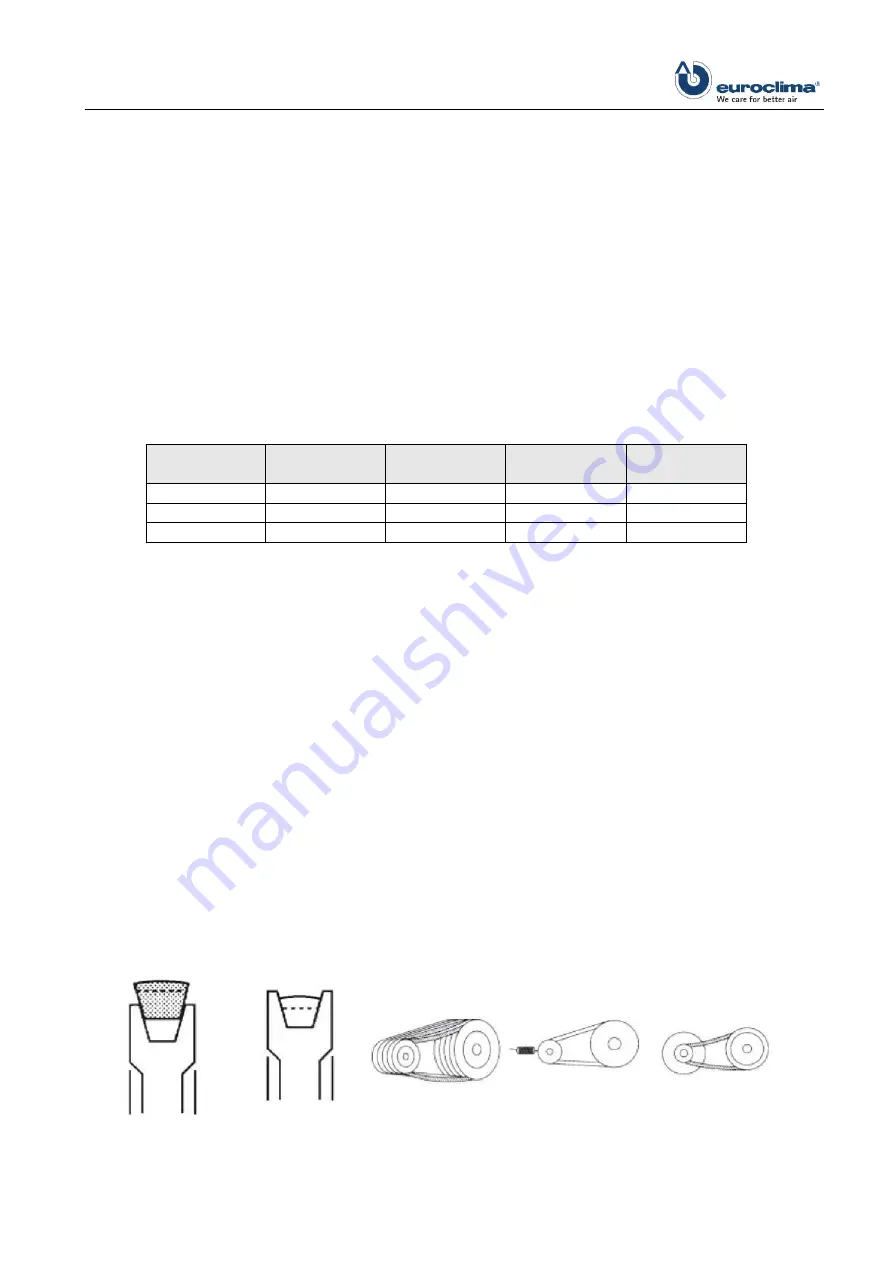

V-belt drive

The V-belt drive is a reliable, low-maintenance component, provided that unfavorable working con-

ditions as shown in

which could reduce durability and result in re-

duced efficiency. The unfavorable conditions include high temperatures and inadequate filtered air

and thus formation of deposits.

-

Check V-belt drive for dirt, damage, wear, tension and alignment (visible inspection)

.

Belts with

damages like cracks or frayed edges must be replaced.

-

Pullies must be checked for fitting, wear and damage.

Reasons for increased belt wear or defect

-

Belt contact the groove bottom / unequal set of belt / tension is too high or too low

–

Figure 200:

Unfavorable operating conditions (1)

Summary of Contents for ZHK Series

Page 1: ...ZHK INSTRUCTION MANUAL ...