www.eurolube.com

–

EUROLUBE EQUIPMENT AB

PART NO 26700, 257-51, 257-52 / ART.NR. 26700, 257-51, 257-52

POWER RAM PUMP HOIST

1

1

R. 09/12 842 806

Samoa Industrial, S.A. · Box 103 Alto Pumarín · 33211 Gijón - Asturias Spain · Tel.: +34 985 381 488 · Fax.: + 34 985 384 163

2012_09_26-10:30

ENGLISH

ESP

AÑOL

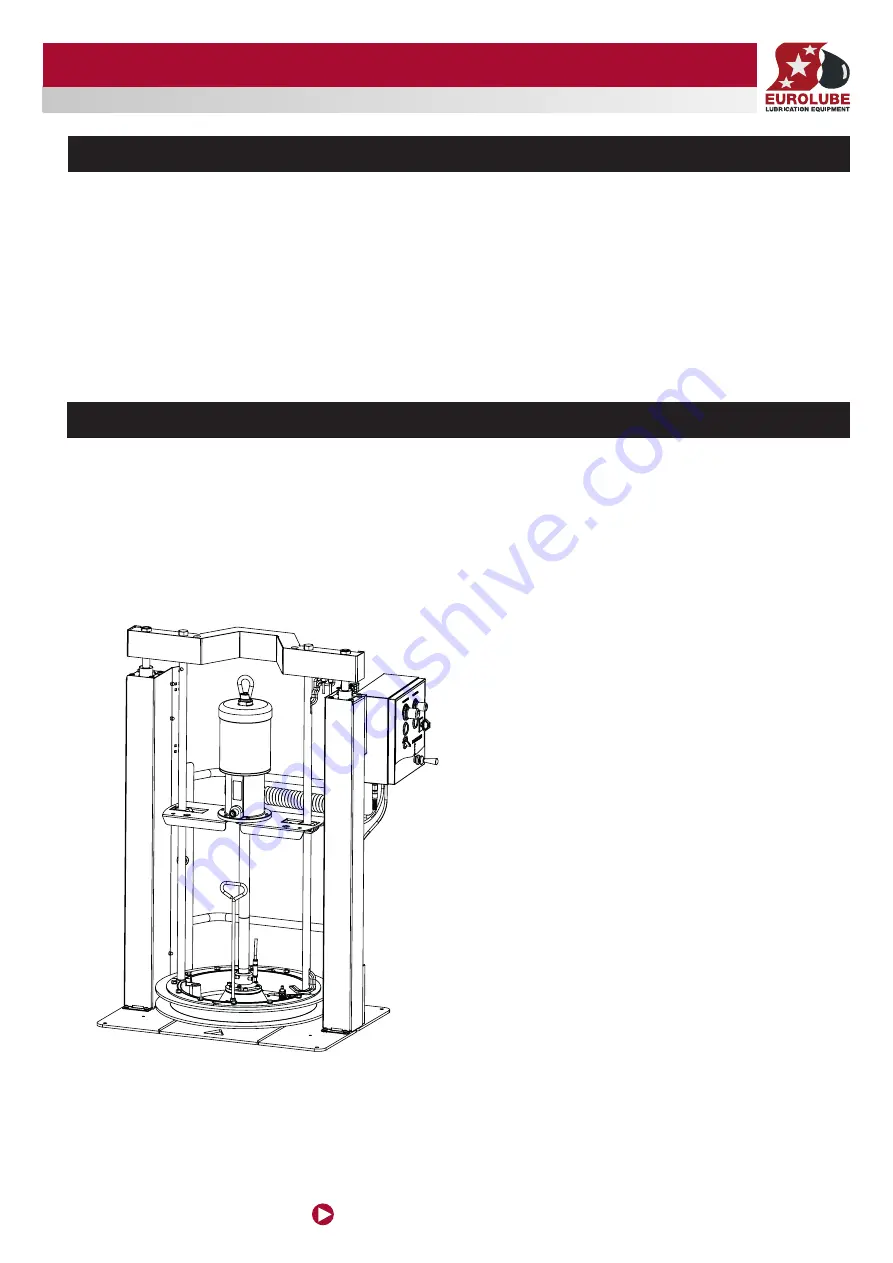

INDUCTOR PLATE FOR 185 KG. DRUMS (POWER RAM)

Part and technical service guide

Part No.:

391 000

424 000

Content

Description ................................................................................ 1

Warning and cautions ................................................................ 2

Installation ................................................................................. 2

Operation ................................................................................. 4

Optional equipments ................................................................. 5

Technical data ............................................................................ 6

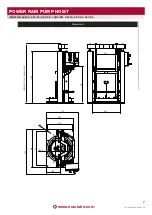

Dimensions ................................................................................ 7

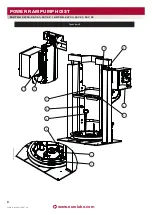

Spare pats .................................................................................. 8

Troubleshooting ....................................................................... 11

Declaration of conformity ........................................................ 12

Fig. 1

Description

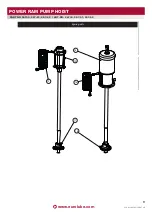

Fixed inductor for the supply of grease, inks, etc. Operated by

compressed air. This unit uses two pneumatic cylinders connected

with a metal structure and protected with metal fairing fixed to

a reinforced base plate, resulting in a very robust piece of

equipment that is very small for the type of drums with which it

can work.

This unit, supplied with all the components necessary for its use,

was designed to supply grease with the greater guarantee of

priming of the pump, and maximum use of the grease drums,

compatible with this model of inductor.

It incorporates a robust aluminium inductor plate, which has a

sealing system made up of lip seals or double O-rings. This system

guarantees the walls of the drum are clean and that it is perfectly

sealed, which stops impurities getting in or simply protects from

the weather. The model and material of the lip or seal used

depends on its compatibility with the substance pumped. There

are also different pump kits designed to optimise the work

depending on the use required of this unit.

When the unit is correctly secured, the plate can be raised

together with the pump to a given height to facilitate changing

the used drum.

This unit has a control cabinet for the inductor and for the pump

installed in the unit. This control cabinet has all the systems

necessary to facilitate the inductor plate going into and out of

the drum.