www.eurolube.com

POWER RAM PUMP HOIST

www.eurolube.com

–

EUROLUBE EQUIPMENT AB

PART NO 26700, 257-51, 257-52 / ART.NR. 26700, 257-51, 257-52

POWER RAM PUMP HOIST

11

11

R. 09/12 842 806

Samoa Industrial, S.A. · Box 103 Alto Pumarín · 33211 Gijón - Asturias Spain · Tel.: +34 985 381 488 · Fax.: + 34 985 384 163

2012_09_26-10:30

ENGLISH

ESP

AÑOL

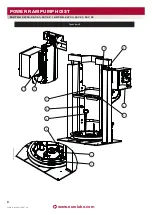

Pos.

Part No.

Description

Qty.

17

42-004-09-73

Adapter Nº 2 plate / PM 3+3

1

842 500

Adaptor gasket

1

940 334

Cylindrical bolt M8x20 DIN-912

6

941 542

Threaded nozzle M10x15 DIN-913

3

942 208

Spring washer B8 DIN-127

6

946 138

O-ring 30x3.5 NBR 70

1

18

42-004-09-72

Adapter Nº1 plate /PM 6

1

842 500

Adaptor gasket

1

940 334

Cylindrical bolt M8x20 DIN-912

6

941 542

Threaded nozzle M10x15 DIN-913

3

942 208

Spring washer B8 DIN-127

6

946 040

O-ring 35x4 NBR 75-80

1

19

931 206

Polyurethane flexible tube D. 8x6 black

5 m

20

931 204

Polyurethane flexible tube D. 6x8 black

3 m

Spare parts

Troubleshooting

Symptoms

Possible Reasons

Solutions

The pump is not working or there is no

fluid delivery.

No suitable air supply pressure.

Increase the air supply pressure.

Some outlet circuit element is clogged or

closed.

Clean or open the outlet circuit.

Air between the follower plate and the

grease.

Bleed the air.

The pump begins to operate very fast.

The drum is empty or the grease level is

beneath the suction tube inlet.

Replace the drum.

The pump keeps on operating although

the grease outlet is closed.

There is a grease leakage in some point of

the circuit.

Verify and tighten or repair.

Grease leakage through the air outlet

muffler.

Grease has passed over to the air motor

caused by worn or damaged packing set.

Replace the packing set (repair kit).

Air leakage through the air outlet

muffler.

The O-rings of the distributor axle or the

bushing worn or damaged.

Replace the axle assembly and/ or the

bushing assembly.

The inverter O-rings are worn or damaged. Replace the inverter O-rings.

Decrease of the grease delivery.

Dirt in upper valve or foot valve.

Dismount and clean, replace if damaged.

Dirt in muffler.

Clean or replace the muffler.

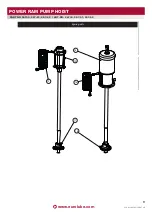

The pump doesn’t lift even without the

pail.

The actuator is not working with proper

pressure.

Regulate the pressure in the actuator

with its control with a pressure higher

than 2 bar.

Leackage between the follower plate

adaptor and the pump’s tube or

between the follower plate and the

adaptor.

The seals are damaged.

Replace the seals from the follower plate

assembly.

Adapter 55:1 Pump Ø30mm

Adapter 50:1 Pump Ø35mm