LUBE-MASTER R10

19(21)

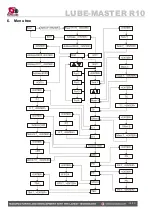

10.1. Connecting a waste oil tank 53132 (2-Levels)

To achieve a proper function, that is the pump stops if the physical tank is full or if the sensor is disconnected, the

following connection should be made.

The TSM port should be set to control the appropriate PC tank in relation to the physical tank.

Correct TankType, TSMAddress and TSMPort should be set using with WinDB Manager

MASK = 13, TankType = 11?.

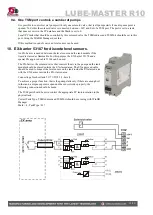

11. To connect an analogue sensor

The four analogue inputs on the TSM support any standard industrial 2-lead / 4-20mA / 24VDC sensors. To connect

sensors a 2-pole connector is used.

11.1. Analogue sensor 53417

The submerged pressure based level sensor

53417 is a robust sensor that can be used with

good accuracy for tanks with a height of 1 – 5

meters. Max height depends on density of fluid.

The measuring resolution for a TSM with a

53417 sensor is 4 mm for water and about 4.5

mm for mineral oil.

Connect the red wire to +24VDC and the black

wire to Sense. +24VDC and Sense are printed on

the PCB.

If the sensor cable (6.5 m) is to short to reach the

TSM it can be lengthen using a standard 2-lead

wire with copper area of 0.5 mm2 for each lead.

For this purpose use the by-packed connection

box.

It is not necessary to use the shield to obtain a good signal because the signal is current based. The shield can be

used for protection grounding purposes if needed.

OBSERVE! It is important that the transparent tube is not blocked and that the humidity protection filter is

used. A blocked tube will cause measuring failure. Not using the humidity protection could

cause sensor malfunction due to corrosion caused by condensed water.