34

The fan blades must be cleaned at least once a year. There are 2 fans: the air fan

(connected to the heater) and the cooling fan. Clean the fan blades with a brush or a

damp cloth; make sure they do not deform or bend! Leave to dry thoroughly before

putting everything back together.

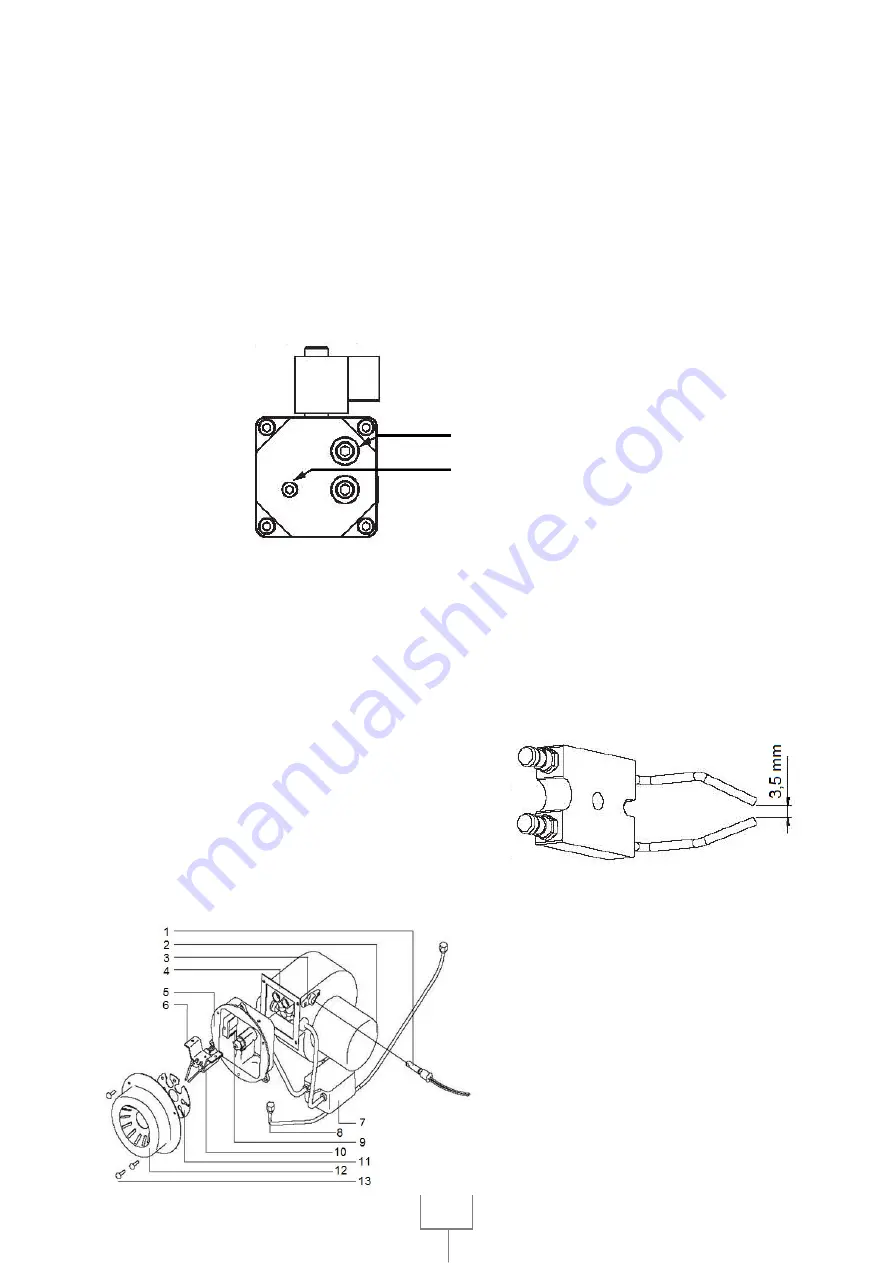

Fuel pump

Clean the filter every 200 operational hours of more if necessary. The pump pressure

can be adjusted with a spanner but has been set correctly in the factory. Do not

adjust at random! A pressure meter must be installed in order to set the pressure.

Pressure must be set to 7-10kg/cm.

Connection point pressure meter

Adjustment point

Nozzle

The nozzle must be cleaned or replaced at least once a year. If contaminated fuel is

used, the nozzle must be replaced immediately. In order to clean the nozzle, you

must remove it from the burner, dismantle it, place it in thinners or petrol for a short

while and then carefully reassemble.

Spark plug

The sparkplug must be cleaned and adjusted

every 600 operational hours and more frequently

if necessary. Remove it from the burner and

clean with a small steel brush. The opening

between the electrodes must be 3.5 mm.

Photoelectric tube

1. Photoelectric tube

2. Air motor

3. Photoelectric tube holder

4. Air fan

5. Burner head

6. Sparkplug holder

7. Ignition

8. High pressure fuel line

9. Nozzle

10. Sparkplug

11. Distributor

12. Diffuser

13. Bolts