REV.0.02_COD.500201_A4

PAG. 29

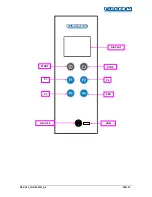

6. CONTROL PANEL AND SYMBOLS USED

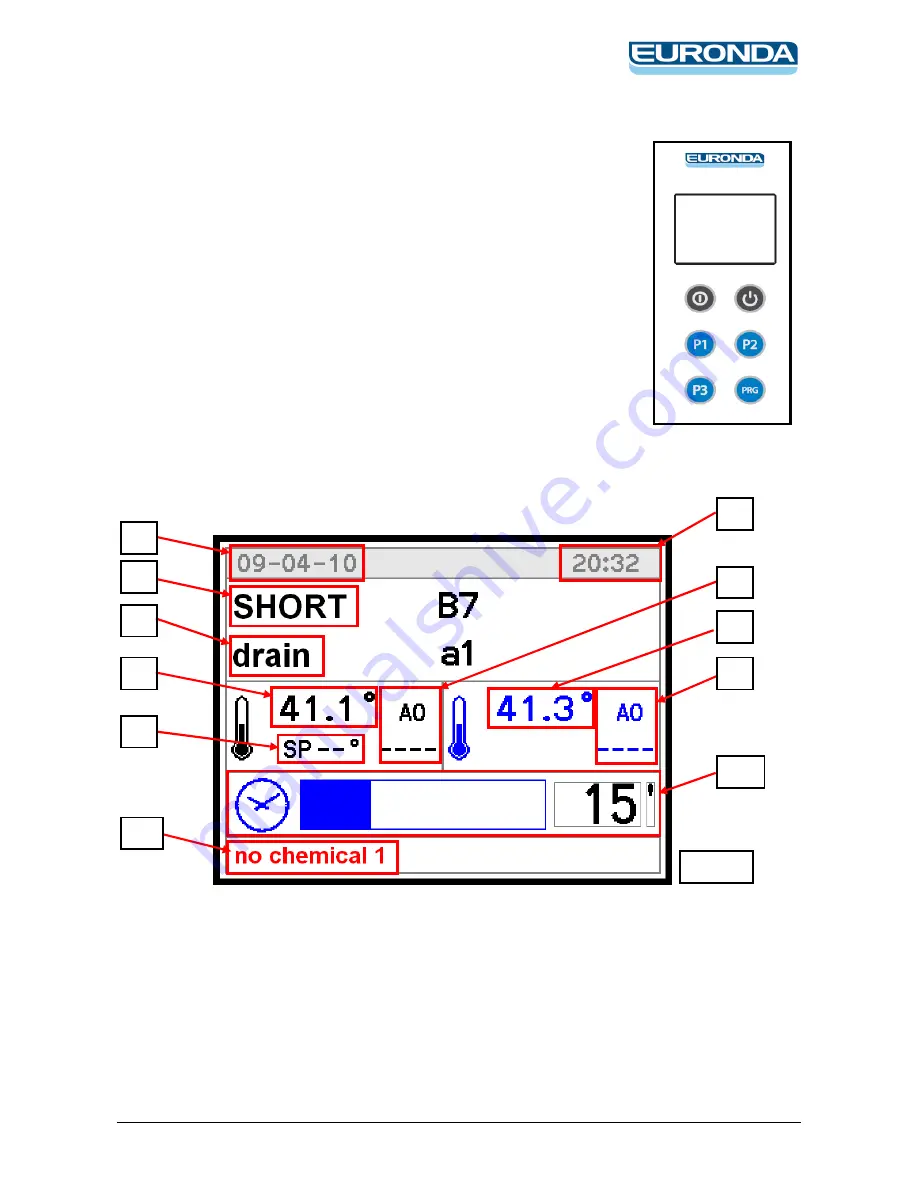

The control panel with liquid crystal display is illustrated in the diagram.

This panel makes the machine easy to use as it indicates the stage of the cycle in

progress, the maximum temperature reached during disinfection and fault messages.

6.1 Control panel (loading side)

DISPLAY LCD

Display the following information:

•

The program selected (1).

•

The phase (2).

•

The date and time (3 and 4).

•

The control temperature (5) and recording temperature (6).

•

The temperature of set-point for the current phase (7).

•

The A0 value for control temperature (8) and for the recording temperature (9).

•

The remaining time (10).

•

Any failure of the machine (11).

1

2

5

7

3

4

8

6

9

10

11

PIC. 1