REV.0.02_COD.500201_A4

PAG. 48

12. CHEMICALS CALIBRATION

Chemical product have different viscosities, so it is recommended to calibrate the dosing system every time you change

the type of chemical.

Depending on machine configuration and set parameter (P8.13 ÷ P8.17), the chemical dosing can be done by time or

impulses (in this case ONLY if it present the flowmeter, ordered as OPTIONAL).

ATTENTION

There is a risk of contact with the chemical product, therefore obtain appropriate individual

protection gear (gloves for protection from chemical substances, breathing protection masks,

goggles etc.) during the execution of operations.

The chemical products are an irritant for the eyes, in case of contact rinse thoroughly with

water and consult a doctor. If these products come into contact with the skin, rinse with plenty

of water.

12.1 Timed dosing

In order to do the chemicals calibration it is necessary to control that the chemical products dosing system is completely

filled.

For this calibration’s procedure it is necessary to have the stopwatch.

12.1.1 Calibration

Insert the suction lance of the chemical to be calibrated into a ml-graduated cylinder and fill it with the chemical up to

250 ml.

Chemical product

To start the calibration of dosing system it is necessary to activate manually the dosing device.

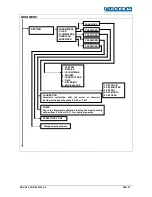

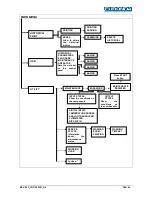

Enter the menu: UTILITY

→

→

→

→

MAINTENANCE

→

→

→

→

Insert 3

rd

level password

→

→

→

→

OUTPUT STATE

Push P1 and P2 buttons to scroll the list of devices and push START button to select the desired device.

After selecting the device to calibrate (see the input/output section 11.6) push P1 button to activated the device and at

same time activate the stopwatch to start measuring the time of dosing.

Push P2 button to deactivate the device when the level of chemical product in ml-graduated cylinder have reached 100

ml and stop the stopwatch.

250 ml