REV.0.02_COD.500201_A4

PAG. 49

Chemical product

Calculate the value of calibration as the ratio between the time measured by the stopwatch and the amount of chemical

product dosed in the cylinder (Ex. 45 sec / 100 ml = 0.45).

Insert the previously calculated value in the relative parameter relative of the doser on the section “EQUIVALENCE”.

12.1.2 Check

After the calibration it is necessary to control the calibration efficacy by the check procedure:

•

Activate manually the dosing device and the stopwatch to start measuring the time.

•

When the stopwatch reaches the dosing time measured in the previous calibration procedure deactivate the

dosing device.

•

Check that the level of product in the ml-graduated cylinder is 100 ml or the same dosed in the previous

calibration procedure.

•

If the level of dosed product is correct the check procedure is finished and continue the chemical calibration for

others dosing devices.

•

If not calculate the new value of the equivalence taking into account the dosage values previously calculated

and the amount of chemical dosed.

Example:

0.45 : 80 = x : 100

•

Insert the new value in the related parameter of the doser on the section “EQUIVALENCE”.

•

Control the calibration consistency with a new check procedure.

AFTER THE CHEMICAL CALIBRATION IT IS NECESSARY TO RUN A RINSING CYCLE WITHOUT INSTRUMENTS

INSIDE THE CHAMBER.

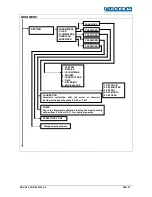

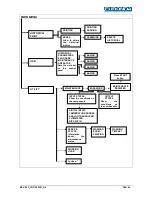

150 ml

Equivalence value

previously calculated.

Chemical dosed during

check procedure.

Chemical to be dosed during

calibration procedure.

New value of

calibration.