Hub van Doorneweg 8 • 2171 KZ Sassenheim – NL •

T

+31(0)252 228850 •

F

+31(0)252 228235 •

E

sales@euronorm.nl •

I

euronormdrives.com

24

25

NEURN030000_220_A

NEURN030000_220_A

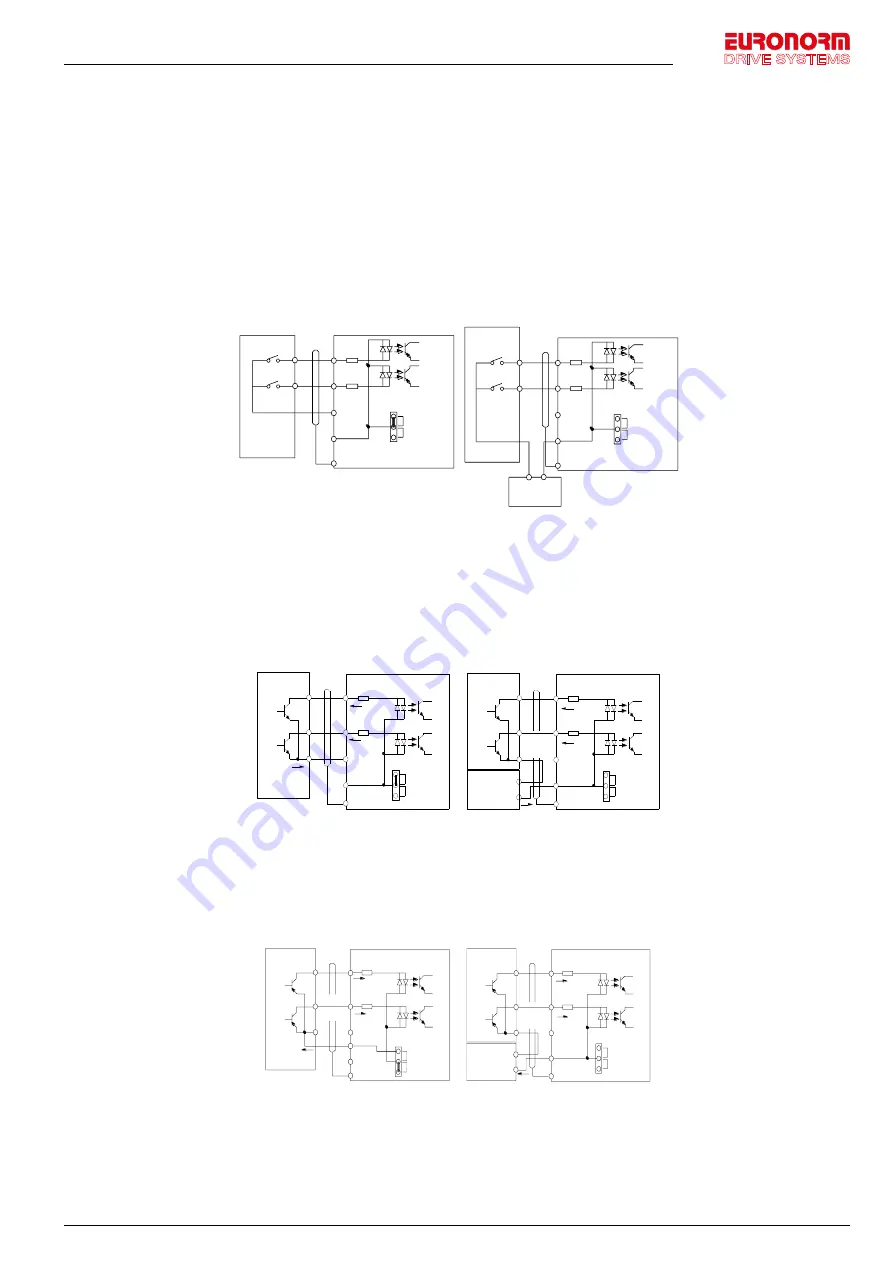

6.4.3 Signal input terminal circuit

Switch input and output signal transmission, generally use the shielded cable and wiring short distance as far as possible,

good grounding and shielding layer on the inverter side, try not to over 20 m transmission distance. Drive in active way,

elected to the power of crosstalk necessary filtering measures are taken, generally recommend that choose dry contact

control mode.

Wiring control cable should be kept with the main circuit and high voltage lines (Such as the power cord, motor

connecting line, relay or contactor) more than 20 cm distance, and to avoid high voltage lines parallel to and can’t be

avoided and the high voltage lines cross, the proposal USES vertical wiring way, in order to prevent the misoperation

caused by disturbance frequency converter

Dry contact mode:

Chapter 4 Installation and commissioning

47

Cha

pt

er 4

+24V

COM

PLC

(Default)

DI1

DI8

COM

PLC

PE

Shielded

cable

External

contactor

Inverter

Inner power supply with main connect

+24V

COM

PLC

(Default)

DI1

DI8

COM

PLC

PE

Shielded

cable

External

contactor

Inverter

External power supply

with main connection

External power

supply

+

-

Figure 4-19

:

Signal input terminal circuit- dry contact mode

Note: using an external power supply, PLC and 24 v jumper cap must be removed, otherwise it

will damage the product.

Open collector NPN connect wire:

When the input signal from the NPN transistor, according to the use of power supply, please

according to the 24 v and PLC jumper cap.

+24V

COM

PLC

(Default)

DI1

DI8

COM

PLC

PE

Shielded

cable

Inverter

Inner power NPN connect mode

External

contactor

+24V

COM

PLC

(Default)

DI1

DI8

COM

PLC

PE

Shielded

cable

Inverter

External power supply NPN connect mode

External

contactor

External

power supply

+

-

Figure 4-20

:

Signal input terminal wiring diagram, open collector NPN connection mode

Note: using an external power supply, PLC and 24 v jumper cap must be removed, otherwise

it will damage the product.

Open collector PNP connection mode:

Signal input terminal circuit- dry contact mode

Note:

using an external power supply, PLC and 24 v jumper cap must be removed, otherwise it will damage the product.

Open collector NPN connect wire:

When the input signal from the NPN transistor, according to the use of power supply, please

according to the 24 v

and PLC jumper cap.

Chapter 4 Installation and commissioning

47

Cha

pt

er 4

+24V

COM

PLC

(Default)

DI1

DI8

COM

PLC

PE

Shielded

cable

External

contactor

Inverter

Inner power supply with main connect

+24V

COM

PLC

(Default)

DI1

DI8

COM

PLC

PE

Shielded

cable

External

contactor

Inverter

External power supply

with main connection

External power

supply

+

-

Figure 4-19

:

Signal input terminal circuit- dry contact mode

Note: using an external power supply, PLC and 24 v jumper cap must be removed, otherwise it

will damage the product.

Open collector NPN connect wire:

When the input signal from the NPN transistor, according to the use of power supply, please

according to the 24 v and PLC jumper cap.

+24V

COM

PLC

(Default)

DI1

DI8

COM

PLC

PE

Shielded

cable

Inverter

Inner power NPN connect mode

External

contactor

+24V

COM

PLC

(Default)

DI1

DI8

COM

PLC

PE

Shielded

cable

Inverter

External power supply NPN connect mode

External

contactor

External

power supply

+

-

Figure 4-20

:

Signal input terminal wiring diagram, open collector NPN connection mode

Note: using an external power supply, PLC and 24 v jumper cap must be removed, otherwise

it will damage the product.

Open collector PNP connection mode:

Signal input terminal wiring diagram, open collector NPN connection mode

Note:

using an external power supply, PLC and 24 v jumper cap must be removed, otherwise it will damage the product.

Open collector PNP connection mode:

Chapter 4 Installation and commissioning

48

Cha

pt

er 4

+24V

COM

PLC

(Default)

DI1

DI8

COM

PLC

PE

Inverter

Inner power PNP connect mode

External

contactor

+24V

COM

PLC

(Default)

DI1

DI8

COM

PLC

PE

Shielded

cable

Inverter

External power supply PNP

connect mode

External

contactor

External

power supply

+

-

+24V

Figure 4-21

:

Signal input terminal wiring diagram, open collector PNP connection mode

Note: using an external power supply, PLC and 24 v jumper cap must be removed, otherwise

it will damage the product.

4-5.

Wiring Precautions

Danger

Make sure that the power switch is in the OFF state before wiring operation, or electrical

shock may occur!

Wiring must be performed by a professional trained personnel, or this may cause damage to

the equipment and personal injury!

Must be grounded firmly, otherwise there is a danger of electric shock or fire hazard !

Note

Make sure that the input power is consistent with the rated value of inverter, otherwise which

may cause damage to the inverter!

Make sure that the motor matches the inverter, otherwise which may cause damage to the

motor or activate the inverter protection!

Do not connect power supply to U, V, W terminals, otherwise which may cause damage to the

inverter!

Do not directly connect braking resistor to DC bus (P), (+) terminals, otherwise which may

cause a fire!

※

The U,V,W output end of inverter can not install phase advancing capacitor or RC

absorbing device. The inverter input power must be cut off when replacing the motor

※

Do not let metal chips or wire ends into inside the inverter when wiring, otherwise which

may cause malfunction to the inverter.

※

Disconnect motor or switch power-frequency power supply only when the inverter stops

output

※

In order to minimize the effects of electromagnetic interference, it is recommended that

a surge absorption device shall be installed additionally when electromagnetic contactor and

relay is closer from the inverter.

Signal input terminal wiring diagram, open collector PNP connection mode

Note:

using an external power supply, PLC and 24 v jumper cap must be removed, otherwise it will damage the product.