Page 15

DV 42 Indoor Gas Fireplace

Installation

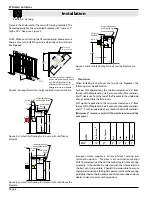

Section 3-3-3: Heat Shields

installing a wall Mounted rHS8 Heat Shield

The RHS8 heat shield CANNOT be used when the termination

is WITHIN (36" minimum horizontal and 46" minimum vertical)

from the fireplace, or directly off the rear of the fireplace, as

shown

Figure 19a

. The RHS101 Heat Shield (

Figure 19c and

19d

) MUST be used within the noted dimensions.

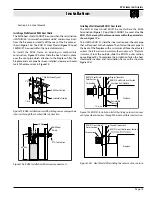

To install the RHS8, frame an opening in combustible

construction,

Figure 19

below. Slide the heat shield in place

over the vent pipe which attaches to the fireplace. After the

fireplace and vent pipe has been installed, clearances should

match the dimensions in

Figure 19

.

Figure 19.

RHS8 Installation. Install by sliding over vent pipe where

it passes through the combustible construction.

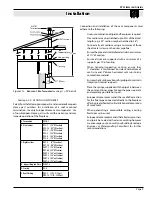

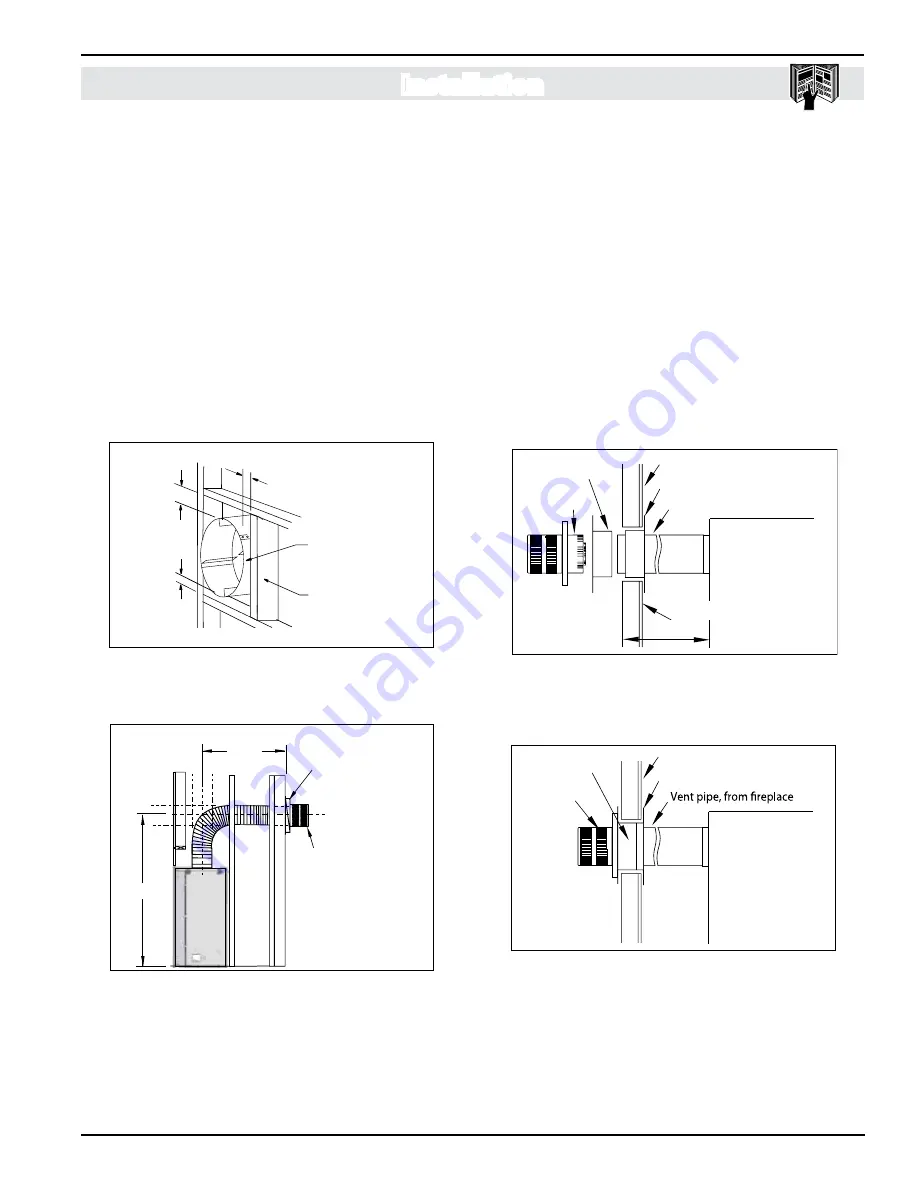

Figure 19c.

RHS101 Installation. Install by sliding outer section over

vent pipe where it passes through the combustible construction.

Figure 19d.

Heat Shield. After sliding the outer section in place.

Termination

Drywall / sheetrock

RHS101 Heat Shield, inner Section

RHS101 Heat Shield

Outer Section

Fireplace

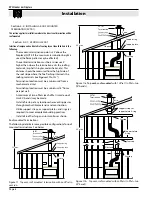

installing a wall Mounted rHS101 Heat shield.

The RHS101 Heat shield MUST be used where the RHS8

Termination (

Figure 19 and 19a

) CANNOT be used.

Use the

RHS101 where any of the dimensions are within the parameters

shown,

Figure 19a.

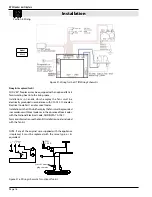

To install the RHS101, slide the inner section over the vent pipe

that will connect to the fireplace. Then fasten the vent pipe to

the back of the fireplace with a minimum of three sheet metal

screws.

(Note: Be certain to maintain the maximum 12" fireplace

clearance).

From the outside, slide the RHS101 outer section

on see

Figure 19c

. To complete the installation fasten the heat

shield outer section and termination frame to the structure

Figure 19d.

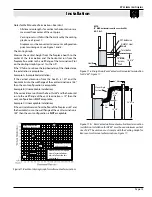

Figure 19a.

RHS8 Installation. Minimum requirements.

RHS8 Heat Shield

1” Min. Both sides Typical

2” Min.

1” Min.

Combustible Framing

12” max

Combustible

framing

Termination

Drywall / sheetrock

RHS101 Heat Shield, inner Section

RHS101 Heat Shield

Outer Section

Fireplace

Vent pipe, from fireplace

RHS8 Heat

Shield

36” Min

46” Min.

PTO Termination