MANUFACTURED BY

EUROSCREEN SRL-ITALY

MADE IN ITALY

SERIAL N.

,

“A”

“B”

“D”

“C”

This document is property of Euroscreen Srl.

Any distribution, reproduction, copying or publication of this document is prohibited.

Installation and maintenance manual

Motorized screen GIOTTO

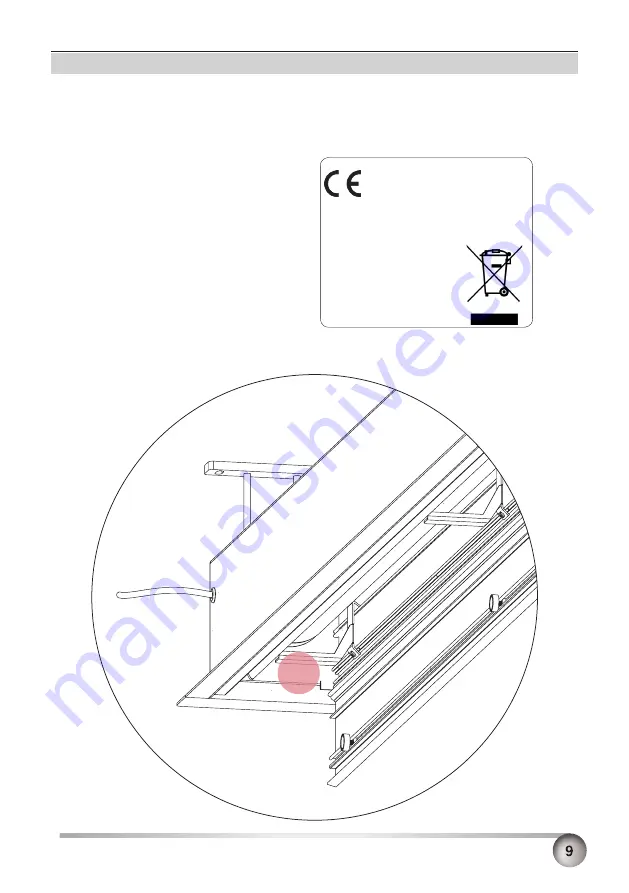

This machine is equipped with labels that contain its basic features.

1.8.1 Label n. 01

It provides the following

information:

A) Serial number

B) Motor power

C) Operating frequency

D) Power consumption

1.8

PRODUCT IDENTIFICATION LABELS

Plate position