e

n

the specific user’s manual

.

Before proceeding, read and understand

the chapter “SAFETY INSTRUCTIONS”

in its entirety.

7.1 DESCRIPTION OF ELEMENTS

SAFETY DEVICE

All the motorcultivators are equipped with

an accident prevention device. Such device

causes the clutch release and the machine

stopping on the single or reverse speed

position, to the release of the control lever,

furthermore such device avoids the reverse

speed insertion if the single speed is on.

CAUTION!

If the machine is on reverse speed the

rotavators are automatically stopping.

CONTROLS DESCRIPTION

1) Accelerator lever control Start-Stop

2) Forward speed lever control.

3) Forward speed lever control

4) Control speed SLOW-FAST (2+2 speed

version only)

5) “Fork on 3 positions”

6) Starter handle

7) Root face control lever.

8)

Cable/belt adjustment control

9)

Handlebar side adjustment lever

THREE-POSITION WHEEL

CLUTCHING DEVICE:

The cultivator is

equipped with a special device called a

“THREE-POSITION FORK”.

- In position

1

(free), the wheel turns freely

on the shaft so that the

machine can move

when the engine is stopped.

- In position

2

(locked), the wheel is inte-

gral with the shaft, setting into drive, mean-

ing ready to start working. This is the most

commonly used position.

- In position

3

(semi-differential), the wheel

can perform about a half-turn turning on the

shaft, in order to allow turns.

CAUTION!

All operations on the three-position fork

must be performed when the engine is at

a standstill.

DANGER!

1.7

1.7

3.2

3.2

7.2 TANK FILLING

Use caution when handling flammable

fluids. Fuel is highly flammable and ex-

plosive.

Do not fill the tank in closed or poorly

ventilated environments.

Before refilling the tank, switch off the

machine and wait until the motor has

cooled down (15-20 min).

Do not smoke or use electron-

ic devices near combustible fluids.

Use suitable, undamaged filling devices

such as fuel cans, funnels, etc.

In case of fuel leakage, move the ma-

chine before starting it up.

When filling operations have been com-

pleted, replace the cap and tighten it

firmly.

7.3 START-UP AND SHUT-DOWN

Check correct functioning of the main-

tained action levers and double safety

command before using the machine. See

the “CABLE ADJUSTMENT” paragraph

to make adjustments. It is forbidden to

use the machine in case of malfunction

of the controls.

CAUTION!

At the first use of the machine it is

absolutely necessary to verify that inside

the chassis is present the lubrication oil.

Do no start the unit/machine on before

having done such control. For additional

information please look at the chapter

GEARBOX 10.5.

CAUTION!

When you have finished the assembly,

switch the machine and check, bringing

the accelerator to the stop position, the

engine shuts completely down.

DANGER!

DANGER!

DANGER!

DANGER!

DANGER!

DANGER!

DANGER!

3.3

3.3

DANGER!

CAUTION!

Before switching the engine on, carefully

check if the motorcultivator is in perfect

good conditions.

1.

Engine instructions:

Carefully read the istructions booklet

enclosed to the relevant engine.

Check if the air filter is clean.

Fill the tank in as per the fuel de-

scribed in the engine specifications

and using a filter filling funnel.

Do not change the calibration of the

speeds control rotation device of the

engine in order not to over-speed it.

2.

3.2

3.2

Put the fork into position

1 (free) so that the wheel could

freely turn on the shaft to allow the

movements.

3. Move the machine to the borders to be

milled.

4.

3.2

3.2

Put the fork into position

2 (blocked) working position.

Check if the gearbox control lever (Fig.

1.7 part 4 only 2+2 speed version) is on

loose position. Adjust the handlebar to

the requested position/height.

5

.

3.4

3.4

How to switch the engine

on:

Open the fuel cap (for the engine

equipped like this), push to halway the

accelerator lever on the handlebar. If

the engine is cold, operate the starter

device on the carburetor.

6. Bring the starter handle

and pull energetically. When the

engine is on, after some bursts/

bangs, put the starter again at rest

position.

7.

Grasp the handlebar, insert the speed

(for 2+2 speed version)

pos.

A

slow

speed

, pos. B

fast speed

(Fig. 1.7)

.

At the beginning we recommend you

to work on position 1, slow speed.

8.

3.6

3.6

Forward speed:

hold the

handlebar, press the safety catch

shown in the figure inwards and then

pull the lever forward with its grip to

its maximum stroke, meaning to its

limit. The lever must be held down

to maintain blade rotation. If you

remove your hand, the lever will rise

and automatically disengage blade

rotation.

9.

3.7

3.7

Reverse speed: l

et go of

the clutch lever (Fig. 3.6) and, after

having pressed the relative safety

3.3

3.3

3.5

3.5

Summary of Contents for MZP 11

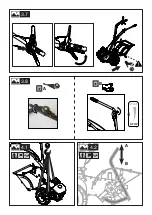

Page 3: ...F A 1 1 1 1 g x2 E C i x1 h x4 l x1 m x2 D B o x2 n x2 x2...

Page 4: ...B 1 3 1 3 1 2 1 2 A g l g h h i h h m m o o n n C C A...

Page 5: ...1 4 1 4 D D...

Page 6: ...1 5 1 5 E E E A B...

Page 7: ...8 B 1 6 1 6 1 7 1 7 1 2 3 5 6 7 8 8 9 4 x B x y y A A x x y y x y x A x x y y A B...

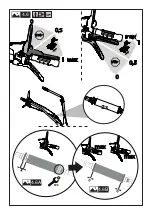

Page 10: ...3 1 3 1 10 m 3 3 3 3 OIL FUEL OIL 4 7 4 7 3 2 3 2 3 1 2...

Page 11: ...3 6 3 6 3 5 3 5 3 4 3 4 START STOP A B...

Page 12: ...3 7 3 7 3 8 3 8 START STOP 4 2 4 2 4 1 4 1 A B A B...

Page 13: ...4 4 4 4 35 35 4 3 4 3 4 5 4 5...

Page 14: ...STOP 1 max 0 5 0 STOP 0 0 5 1 max M10 X 0 0 max max max max 2x 4 6 4 6 4 6A 4 6A 4 6B 4 6B...

Page 15: ...4 7 4 7 1 O IL 2 Max oil level 1 1 2...

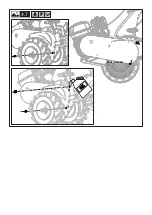

Page 58: ...el 1 1 1 1 2 CE 1 3 2 1 2 1 1 4 CE CE 2 1 2 1 1 2 3 4 5 6 7 8 2 1 16 2 3 4 5 6 80 7 8 9 10 1...

Page 63: ...el SAE 80 10 6 21 PSI 1 5 bar PSI 11 20 11 10 6 10 4 60 10 5 12 13 7 2 START 1 7 3 10 4 10 4...

Page 64: ...el 14 14 1 2002 95 CE 2002 96 CE 2003 108 CE 14 2 81 08...