3200 Series

114 Part No HA028651 Issue 7.0 Apr-09

17.10.2

Example 2: Using the Wizard

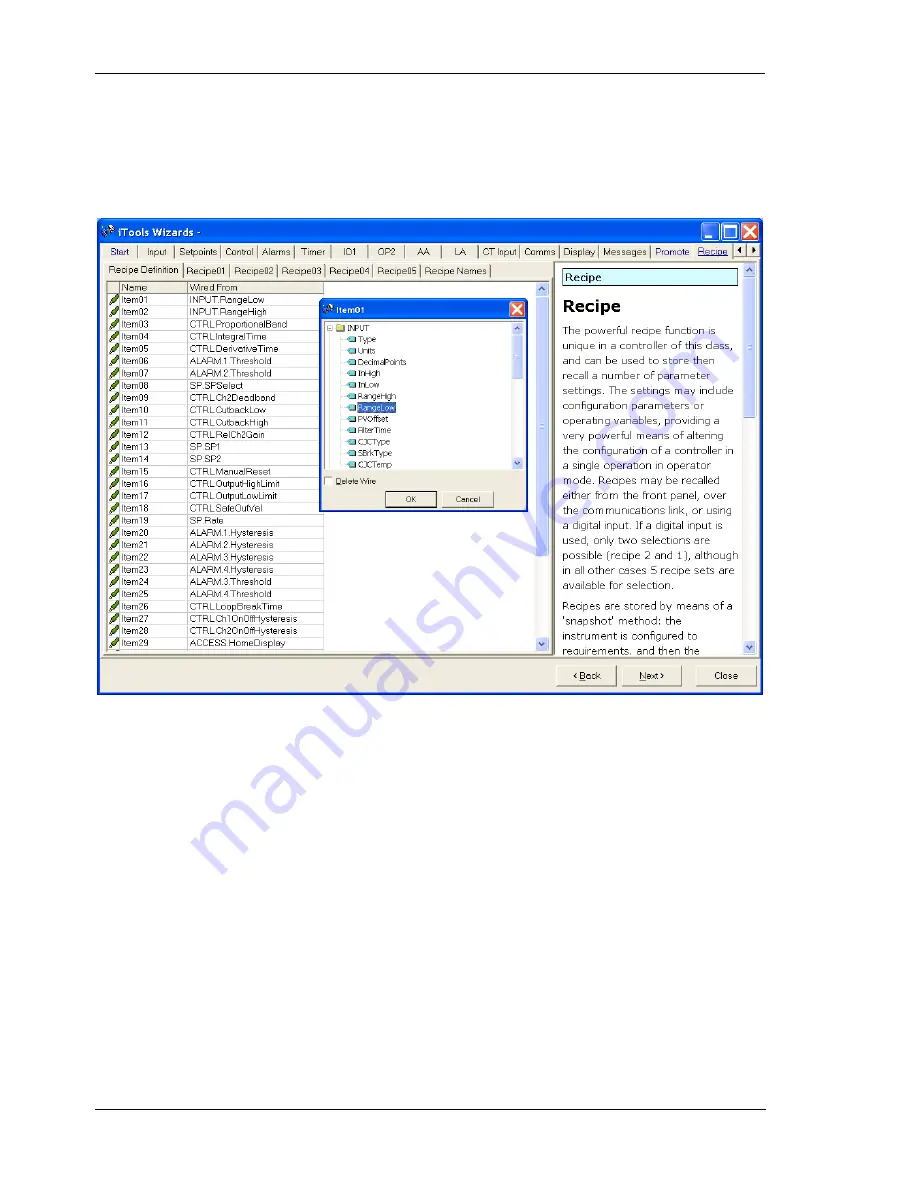

Select the ‘Recipe’ tab

17.10.2.1

Recipe Definition

Select ‘Recipe Definition’ tab to display the default parameters available to be stored in recipe. Double click on the

parameter in the ‘Wired From’ column, a pop up allows you to delete or change to a different parameter.