3200 Series

36 Part No HA028651 Issue 7.0 Apr-09

7.

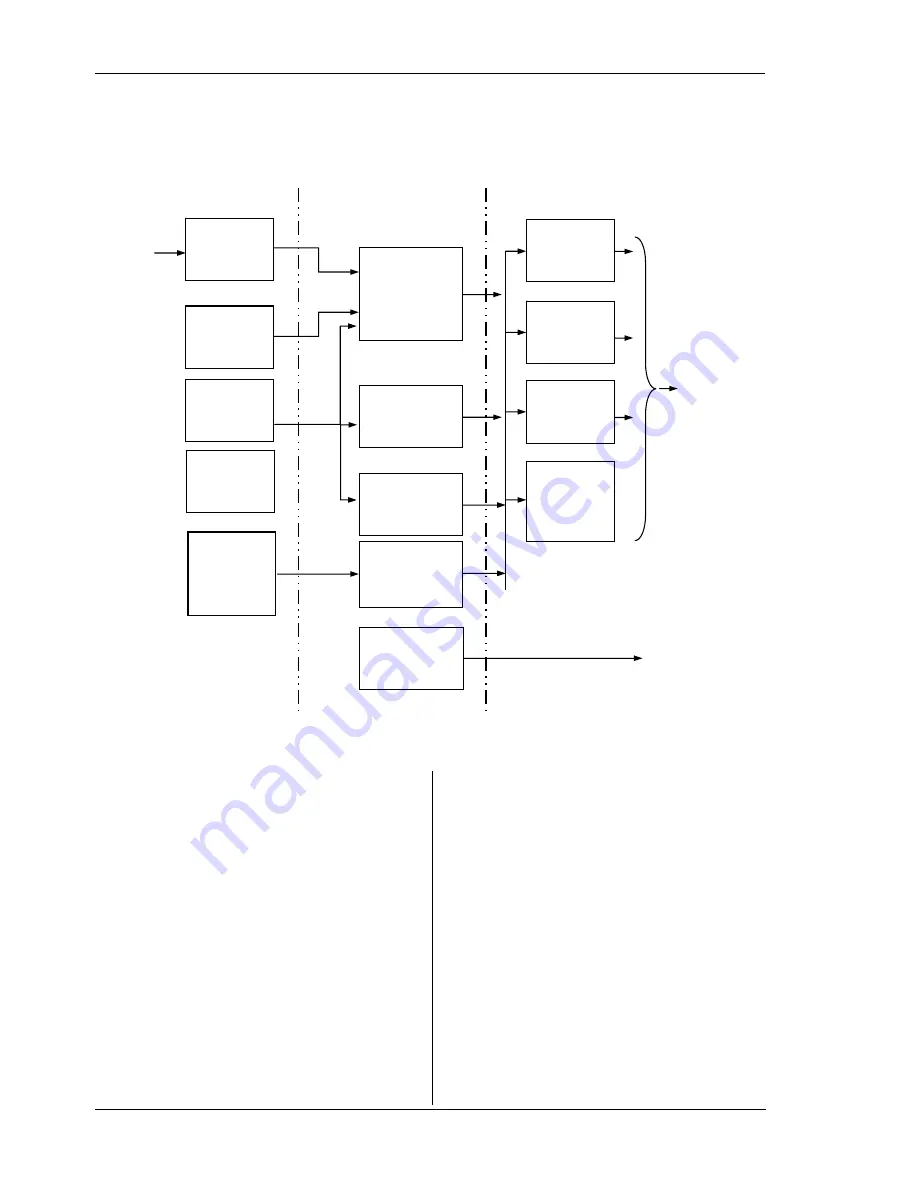

Controller Block Diagram

The block diagram shows the simple building blocks which make up the controller. Each block has a list of parameters

headed by a list name. For example the ‘Input List’ contains parameters which define the input type.

The quick start code automatically sets the parameters to match the hardware.

The Temperature (or Process Value, PV) is measured by

the sensor and compared with a Setpoint (SP) set by the

user.

The purpose of the control block is to reduce the

difference between SP and PV (the error signal) to zero

by providing a compensating output to the plant via the

output driver blocks.

The timer and alarms blocks may be made to operate

on a number of parameters within the controller, and

digital communications provides an interface to data

collection and control.

The way in which each block performs is defined by its

internal parameters. Some of these parameters are

available to the user so that they can be adjusted to suit

the characteristics of the process which is to be

controlled.

These parameters are found in lists and the name of

each list corresponds with the name of the function

block shown in the above diagram.

The above block diagram applies to 3208, 32h8 and

3204 controllers.

For 3216 Output 3 and Logic Input B are not present.

Sensor

eg thermocouple

Output 4 (AA

Relay)

Eg Alarm

AA

List

(section 9)

To plant

actuator

devices

Sensor Input

Input List

(section 8)

Setpoint

SP

List

(section 10)

Control

CTRL

List

PID/on-

off/Tune/Auto-Man

(section 11)

Input/Output 1

Eg Heat

I O-1

List

(section 9)

Output 2

Eg Cool

OP-2

List

(section 9)

Alarm(s)

ALARM

List

(section 12)

Timer

TI MER

List

(section 13)

Digital

Communications

COMMS

List

(section 15)

RS232

Or

RS485

Digital Input A

LA

List

(section 9)

CT Alarm setting

CT

List

(section 9)

Current

Transformer

Input

CT

List

(section 9)

Inputs Control

Processes

Outputs

Output 3

Eg Cool

OP-3

List

(section 9)

Digital Input B

LB

List

(section 9)