EVCO | 21.10.2020 | AZ

| 29

144EJBSI104

EVLJBOX HP Sequencer -

Application manual

Main regulation

Main regulation is a regulation in the incremental neutral zone based on the differential from the temperature setpoint of

the regulation temperature. The procedure will be different according to the operating mode set by parameter

MOdE

.

Every time the operating mode changes, regulation is blocked for 30 seconds to prevent communication problems with the

slaves.

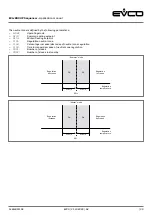

When heat regulation is requested, a slave is activated and incremented up to 100%, according to the regulation timing set.

It will then move on to the next slave, incrementing it by 100%, and continue in this manner until the maximum number of

slaves configured have been incremented.

Vice versa, when the request for heat regulation expires, one slave is decreased to 0% and then deactivated. It will then

move on to the next slave, decreasing it to 0%, and continue in this manner until it has run down all the configured slaves.

It is possible to restrict the number of slaves to activate simultaneously by leaving the remaining slaves in stand-by through

parameter

PG02

.

Two dedicated setpoints will be loaded according to the operating mode:

–

Summer mode/cooling (

MOdE = 0

)

the summer setpoint set by parameter

SEtC

will be loaded

–

Winter mode/heating (

MOdE = 1

)

the winter setpoint set by parameter

SEtH

will be loaded

In CHILLER slaves where the machine is a chiller only (

PG01 = 0

or

PG01 = 2

), the operating mode is limited to summer mode

only and any changes made to parameter

MOdE

will have no effect.

The application, which decides the regulation probe to use, will interrogate the slaves in a register called MODBUS to find

out if they are reversible or non-reversible.

As regards HPRU slaves, the kind of condenser set by parameter

PF60

will be taken into consideration

:

–

if

PF60 = 0

(air) or

PF60 = 2

(water) the machine is reversible

–

if

PF60 = 1

(water) the machine is not reversible

For

CHILLER slaves, the type of machine set by parameter

PG01 will be taken into consideration

:

–

if

PG01 = 0

(Air-Water chiller only) or

PG01 = 2

(Water-Water chiller only) the machine is not reversible

–

if

PG01 = 1

(Air-Water HP) or

PG01 = 3

(Water-Water HP) the machine is reversible

If the operating mode is set to winter (

MOdE = 1

) and the slaves are not reversible, the regulation probe will be the

condenser output probe. In all other cases, the evaporator output probe will be taken into consideration.

Regulation will be blocked in the following cases:

–

MODBUS communication not yet enabled after the sequencer has been switched on

–

Regulation probe disconnected or showing an error

–

Slave configuration alarm due to discrepancies between the types of slaves (HPRU and CHILLER in the same network) or

between the types of condenser (air and water reversible/non reversible in the same network)

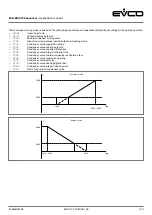

A request for heat regulation is made if:

–

In summer: the regulation temperature is above the setpoint

SEtC

plus the neutral zone

Pr01/2

–

In winter: the regulation temperature is below the setpoint

SEtH

minus the neutral zone

Pr01/2

The request will be met if:

–

In summer: the regulation temperature is below the setpoint

SEtC

minus the neutral zone

Pr01/2

–

In winter: the regulation temperature is above the setpoint

SEtH

plus the neutral zone

Pr01/2