-6-

Pay close attention to the order of the sink flange

parts, as they have been correctly assembled by the

factory.

A. Disassemble the sink flange assembly from the

disposer by turning the mount ring to the left (clockwise)

and removing it.

B. Raise the mount ring toward the top of the sink flange.

Remove the cushion mount and the mount ring. You may

want to practice installing the cushion mount at this point

before you are under the sink.

C. Unscrew the support ring from the sink flange and

remove the fiber gasket. You are now left with the sink

flange and the rubber gasket.

E. If no putty is used, insert the sink flange through the

rubber gasket into the sink opening. Do not turn the

flange once it is seated.

F. If you use putty instead of the gasket, form a ring

around the underside of the sink flange. Insert the flange

into the sink opening, press down hard to squeeze out

excess putty. From under the sink, trim off excess putty

flush with the bottom edge of the sink opening.

G.From underneath the sink, slip the fiber gasket onto

the exposed sink flange. With arrows pointing up, screw

the support ring onto the sink

flange and hand tighten until

the sink flange will not move.

At this point you may want to

insert the stopper in the sink

and fill with water to check

the sink flange seal and insure there are no leaks.

H.Place the mount ring over the sink flange and hold in

place while installing the cushion mount (large side

down). Make sure the groove on the inside of the cushion

mount fits over the lip on the

sink flange, similar to putting

the on a plastic container Run

your fingers around the entire

cushion mount with slight

pressure. Do not press too

hard. When the cushion

mount is properly seated,

the mount ring can be

pulled downward over the

cushion mount and will be

free to turn.

NOTE:

D. The rubber gasket is used instead of plumbers

putty with stainless steel sinks. Some cast sinks will

require putty.

.

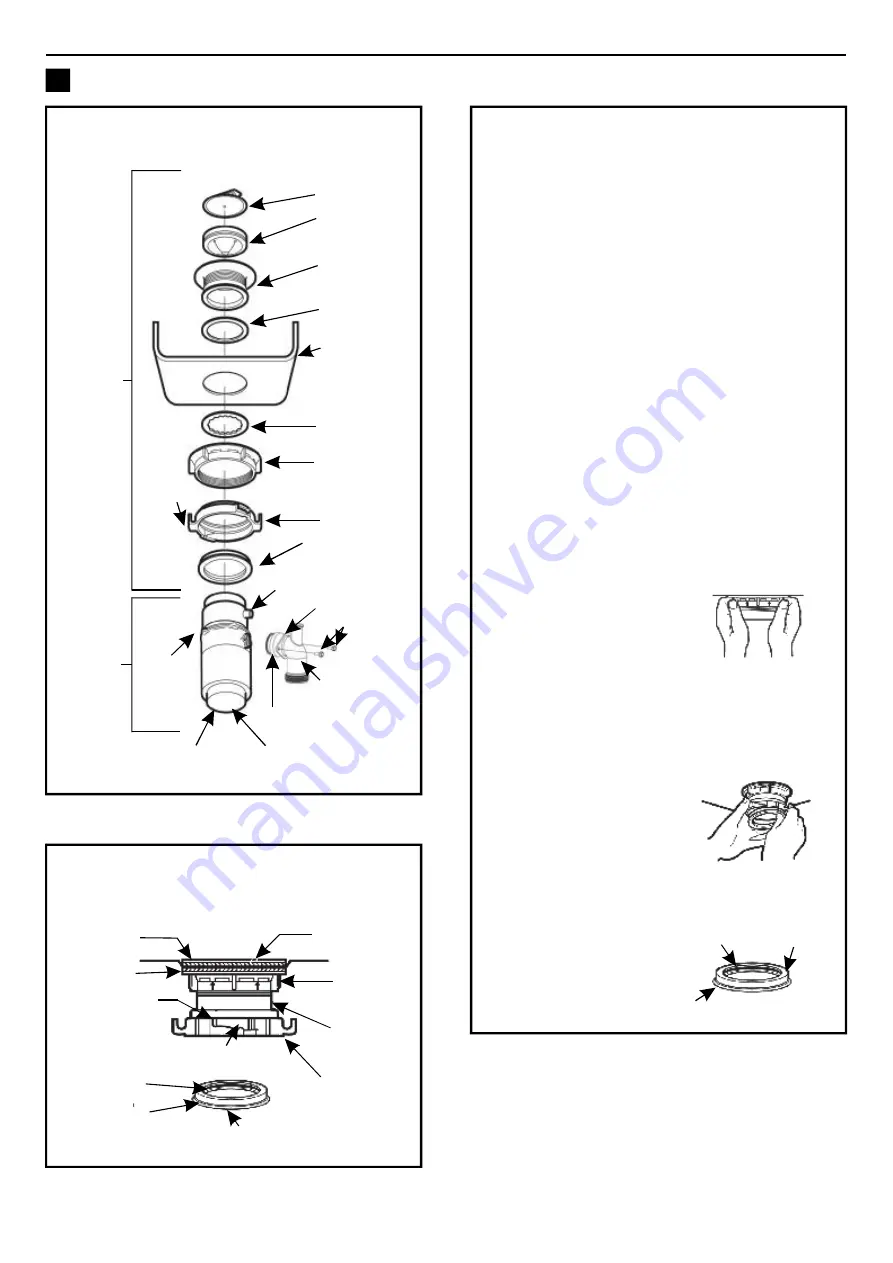

COMPONENTS

Sink Flange

Assembly

Stopper

Removable

Splash Guard

Sink Flange

Rubber Sink

Flange Gasket

Sink

Fiber Gasket

Support Ring

Note Arrows

Indicating Up

(

)

Mount Ring

Cushion Mount

Note TOP Mark

(

)

Elbow Flange

Screw

Discharge

Elbow

Elbow Gasket

Rating Label in This Area

End Bell

Electrical Connections

(

)

Hopper

INSTALLATION OF SINK FLANGE

Correctly Installed Sink Flange

Sink

Rubber Gasket

Sink Flange

Fiber Gasket

Sink Flange

Support Ring

Mounting Ring

should be free

to move up and down

Cushion Mount

Installation Instructions

1

COMPONENTS AND INSTALLATION

Disposer

Tightening

Ears

Dishwash Discharge Inlet

(

.)

Read completely before starting

Bottom Bead of

Cushion Mount

Open Area

No Obstruction

Groove

Bottom Bead

(

)

Shown for proper orientation

Hand tighten sink flange

-

Cushion Mount Detail

Top

Groove

Bottom Bead

Summary of Contents for FDW560

Page 1: ...Instruction Manual FOOD WASTE DISPOSAL FDW560...

Page 2: ......