Glass Kiln

General Operation Manual

North American Models

May 2015

Page

16

of

17

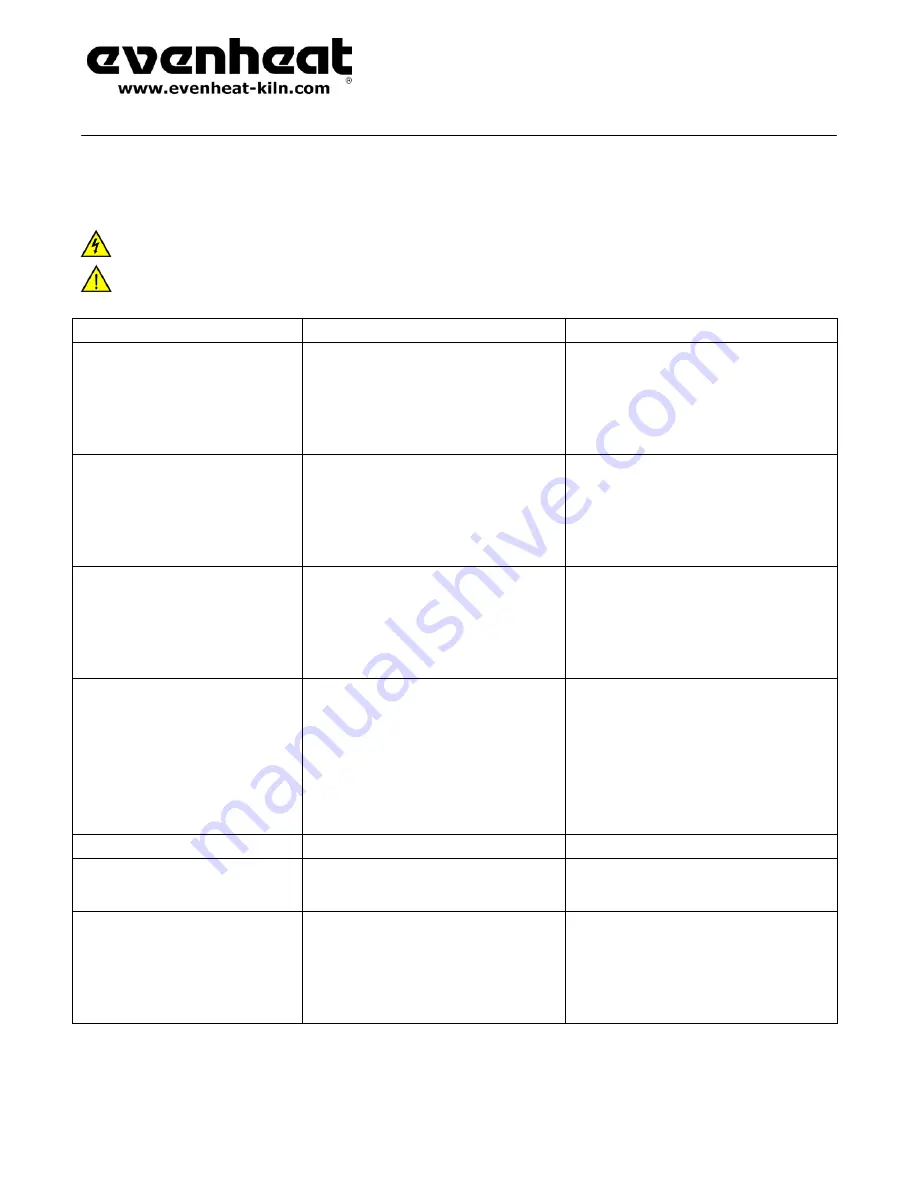

Trouble Shooting

All Kilns are tested and checked at the factory before being cleared for shipment. Most problems with newly installed kilns are in the customers’ service to

the kiln. Even if installed by an electrician the main problems are: wire size, circuit breaker or fuse size being too small, loose connections, etc.

When working on repairs, be sure power supply cord is removed from wall receptacle and all power is turned off.

A qualified electrician or service person should do all repairs and follow all local, state and federal codes.

The electrical supply going into a kiln can be dangerous if not done properly.

IMPORTANT – Check electrical specifications.

TROUBLE

PROBABLE CAUSE

CORRECTIONS

Controller Program Running and Kiln

doesn’t heat or Switches on and Kiln

doesn’t heat.

(a)

Blown fuse/tripped circuit breaker

(b)

Kiln NOT plugged in

(c)

Loose connection

(d)

Faulty switch

(e)

Element burned out

(f)

Stuck relay

(g)

Improper data programmed

(a)

Replace fuse/reset circuit breaker

(b)

Plug kiln in

(c)

Tighten

(d)

Replace

(e)

Replace

(f)

Replace

(g)

Review and re-enter data

Fuse blows/circuit breaker trips as soon as

kiln is turned on.

(a)

Short in Kiln

(b)

Service wired wrong

(c)

Fuse or circuit breaker too small

(d)

Overloaded circuit

(a)

Check wiring

(b)

Have electrician check service from fuse box

to kiln

(c)

Check electrical specifications – replace with

right size (see note at bottom)

(d)

Disconnect all other appliances, etc. from

circuit

Fuse blows/circuit breaker trips during

firing.

(a)

Defective fuse(s) or worn circuit breaker

(b)

Fuse, wire size or circuit breaker too

small

(c)

Overloaded circuit

(d)

Loose or corroded connections

(e)

Short in kiln

(a)

Replace fuse(s) or breaker

(b)

Check electrical specifications – replace with

right size (see note at bottom)

(c)

Disconnect all other appliances, etc. from

circuit

(d)

Tighten or clean

(e)

Check wiring

Kiln takes too long to fire.

(a)

Voltage too low

(b)

Service wired wrong

(c)

Loose connection between fuse box and

kiln wiring

(d)

Element or switch burned out

(e)

Elements gradually wearing out

(f)

Relay stuck

(g)

One side of fuses or breaker blown

(h)

Improper data programmed

(a)

Have electrician or power company check

voltage – see specifications

(b)

Have electrician check service – see

specifications

(c)

Check and tighten all connections

(d)

Replace

(e)

Replace

(f)

Replace

(g)

Replace

(h)

Review and re-enter data

Kiln heats with Computer Controller off.

(a)

Relay Stuck

(a)

Replace

Kiln shuts off too soon.

(a)

Fuse blows/circuit breaker trips

(b)

Computer controller displays Error

Message

(a)

Replace fuse/reset circuit breaker

(b)

See Computer Controller Operating

Handbook

Hot or partially melted plug or wall

receptacle * Kiln should be shut down

immediately – DISCONNECT POWER.

(a)

Loose connection at wall receptacle

(b)

Worn receptacle or plug

(c)

Defective cord

(d)

Corroded cord prongs/or receptacle

terminals

(a)

Have electrician check and tighten

connections

(b)

Have electrician replace

(c)

Replace immediately

(d)

Sand cord prongs to remove corrosion. A

qualified electrician can replace cord or

receptacle if needed.