Glass Kiln

General Operation Manual

North American Models

May 2015

Page

8

of

17

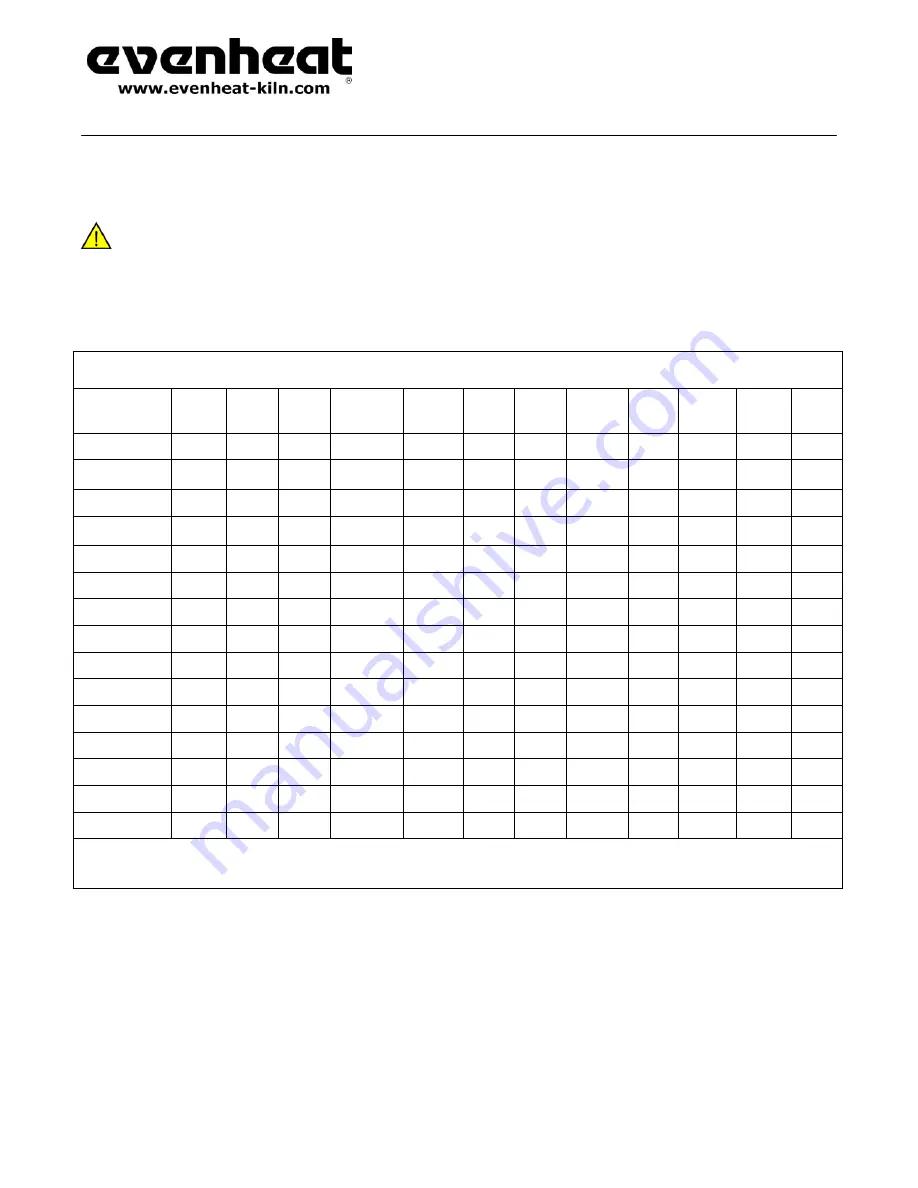

Electrical Service Specifications

Connection

To operate safely and efficiently your kiln needs the proper electrical outlet with the correct amperage capacity and voltage. A licensed electrician

or local power authority should determine if you have the proper service. All electrical changes should be performed by a licensed electrician.

Refer to the beginning of this manual for a list of precautions that must be followed. It is very important that all wire size and fusing/breaker selections are

correct. Improper selection can lead to overheating of the cordset, receptacle, supply lines and fusing/breaker. Copper wire is preferred and we strongly

suggest avoiding aluminum wire.

Through common sense and professional electrical service your kiln will provide many years of trouble free service.

Glass Kiln Electrical Specifications

Model

Width

Length

Depth

Max.

Temp

Cubic

Feet

Volts

Amps

Watts

Fuse

Size

Min.

Wire

Size

USA

NEMA

Config.

Ship

Weight

Copper

10.0”

6.5”

9.0”

2200°F

.340 ft

3

120V

12A

1440W

15A

12AWG

5-15R

54 lb.

Studio 8

Studio Pro

8.0”

8.0”

4.5”

1800°F

.367 ft3

120V

12A

1440W

15A

12AWG

5-15R

30 lb.

Fishbone

14.25”

3.5”

7.5”

1200°F

.22 ft

3

120V

12A

1440W

15A

12AWG

5-15R

45 lb.

Hot Shot

GT 14-6

14.5”

N/A

6.5”

1800°F

.700 ft

3

120V

12A

1440W

15A

12AWG

5-15R

70 lb.

TGK GT 4050

19.75”

15.75”

6.5”

1650°F

1.17 ft

240V

15A

3600W

20A

12AWG

6-20R

135 lb.

Studio Pro 14

14.5”

14.5”

6.5”

1650°F

.80 ft

3

120V

15A

1800W

20A

12AWG

5-15R

130 lb.

Studio Pro 15

14.5”

14.5”

6.5”

1650°F

.80 ft

3

120V

15A

1800W

20A

12AWG

5-15R

120 lb.

Studio Pro 17

17”

17”

6.5”

1650°F

1.1 ft

3

120V

18A

2160W

20A

12AWG

5-20R

130 lb.

GTS 18-9

17.5”

N/A

9.0”

1800°F

1.30 ft

3

240V

27A

6460W

40A

8AWG

6-30R

100 lb.

GTS 23-9

23.5”

N/A

9.0”

1800°F

2.34 ft

3

240V

30A

7200W

40A

8AWG

6-50R

140 lb.

GTS 23-13

23.5”

N/A

13.5”

1800°F

3.51 ft

3

240V

30A

7200W

40A

8AWG

6-50R

195 lb.

Studio Pro 24

24”

24”

13.5”

1800°F

4.20 ft

3

240V

32A

7680W

40A

8AWG

6-50R

280 lb.

GTS 2541-9

41.0”

25.5”

9.0”

1800°F

4.80 ft

3

240V

40A

9600W

50A

6AWG

6-50R

280 lb.

GTS 2541-13

41.0”

25.5”

13.5”

1800°F

7.20 ft

3

240V

40A

9600W

50A

6AWG

6-50R

310 lb.

Studio Pro 41

40.5”

25.25”

13.5”

1800° F

7.52 ft

3

240V

45A

10,800W

50A

6AWG

6-50R

365 lb.

Specifications subject to change without notice or obligation. Standard production models are 120V and 240V, single phase.

Other voltage and phase configurations are available including 100V, 200V, 208V, and 380/400/415V.