Rev. 03/08/04

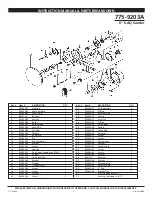

775-9203A

5

PLEASE REVIEW ALL WARNING INSTRUCTIONS PRIOR TO OPERATION. SAVE THIS MANUAL FOR FUTURE REFERENCE.

IMPACT WRENCHES

TOOL RUNS SLOWLY OR NOT AT ALL AND/OR AIR FLOWS ONLY SLIGHTLY FROM EXHAUST

— This is probably caused

by: air flow blocked by dirt build-up; motor parts jammed with dirt; power regulator has vibrated to closed

position.

YOU SHOULD:

Check air inlet strainer for blockage. Pour a generous amount of air tool oil into air inlet. Operate

tool in short bursts, in both forward and reverse motion. Repeat if necessary. If tool performance is not

improved, it should be serviced at an authorized service center.

TOOL WILL NOT RUN, EXHAUST AIR FLOWS FREELY

. This is probably caused by one or more motor vanes stuck due

to accumulation of sludge or varnish; motor rusted.

YOU SHOULD:

Pour a generous amount of air tool oil into air inlet. Operate tool in short bursts, in both forward and

reverse motion. Lightly tap motor housing with plastic mallet. Detach air supply. Try to free motor by turning

drive shank manually, if possible. If tool remains jammed, it should be serviced at authorized service center.

SOCKETS WILL NOT STAY ON.

This is probably caused by: worn socket retainer ring or soft back-up ring.

YOU SHOULD:

Wear safety goggles. Detach air supply. Using external retaining ring pliers, remove old retaining ring.

Holding square drive with appropriate open-end wrench, use small screwdriver to pry old retainer ring

out of groove. Always pry off ring away from your body - it can be propelled outward at high velocity. Replace

back-up O-ring and retainer ring with correct new parts. (See breakdown). Place retaining ring on table, press

tool anvil into ring in a rocking motion. Snap into groove by hand.

PREMATURE ANVIL WEAR.

This is probably caused by: use of chrome sockets or worn sockets.

YOU SHOULD:

Stop using chrome sockets. Chrome sockets have a hard surface and a soft core. Drive hole becomes

rounded - but will still be very hard. Besides the danger of splitting, wrench anvils will wear out prematurely

when used with chrome sockets.

TOOL SLOWLY LOSES POWER BUT STILL RUNS AT FULL FREE SPEED.

This is probably caused by: worn clutch parts,

due to inadequate lubrication; engaging cam of clutch worn or sticking due to inadequate lubrication.

YOU SHOULD:

FOR OIL LUBED WRENCHES - check for presence of clutch oil (where oil is specified for clutch) and

remove oil fill plug; tilt to drain all oil from clutch case; refill with 30 weight SAE oil or that recommended by

manufacturer, in the specified amount. Also check for excess clutch oil. Clutch cases need only be filled 50%.

Overfilling can cause drag on high speed clutch parts. A typical 1/2" oil-lubed wrench only requires 1/2 ounce of

clutch oil. FOR GREASE LUBED WRENCHES - Check for excess grease by rotating drive shank by hand. It should

turn freely. Excess is usually expelled automatically.

TOOL WILL NOT SHUT OFF.

This is probably caused by: throttle valve O-ring broken or out of position or throttle

valve stem bent or jammed with dirt particles.

YOU SHOULD:

Remove assembly and install new O-ring. Lubricate with air tool oil and operate trigger briskly. If

operation cannot be restored, tool should be serviced at authorized service center.

AIR RATCHETS

MOTOR RUNS. SPINDLE DOESN'T TURN, OR TURNS ERRATICALLY

— This is probably caused by: worn teeth on ratchet

or pawl; weak or broken pawl pressure spring; weak drag springs fail to hold spindle while pawl advances for

another bite.

YOU SHOULD:

Have replacement parts installed by authorized service center.

TOOL DOESN’T RUN, RATCHET HEAD INDEXES CRISPLY BY HAND—

This is probably caused by: dirt or sludge

build-up in motor parts.

YOU SHOULD:

Pour a generous amount of air tool oil into air inlet. Operate throttle in short bursts. With socket

engaged on bolt, alternately tighten and loosen bolt by hand. If tool remains jammed, it should be serviced at

authorized service center.

TROUBLESHOOTING

Summary of Contents for 775-9203A

Page 12: ...Rev 03 08 04 775 9203A 12...