DEAR USER:

Everest Refrigeração Indústria e Comércio Ltda, congratulates you for choosing to purchase your

Automatic Ice Cube Machine. In our industry, everything was done to make sure that your

machine will have the best performance for many years to come. Your collaboration is required by,

first reading this manual carefully, and then using it as recommended below.

In all of the

AUTOMATIC ICE CUBE MACHINE

models, improvements were made in mechanics

and electronics that resulted in a 40% reduction in the consumption of waste water,

improvements on the physical appearance of the ice and the ability to identify anomalies in

equipment operation, working to correct and/or protect the equipment, preventing damage to

the main components.

INTRODUCTION

2

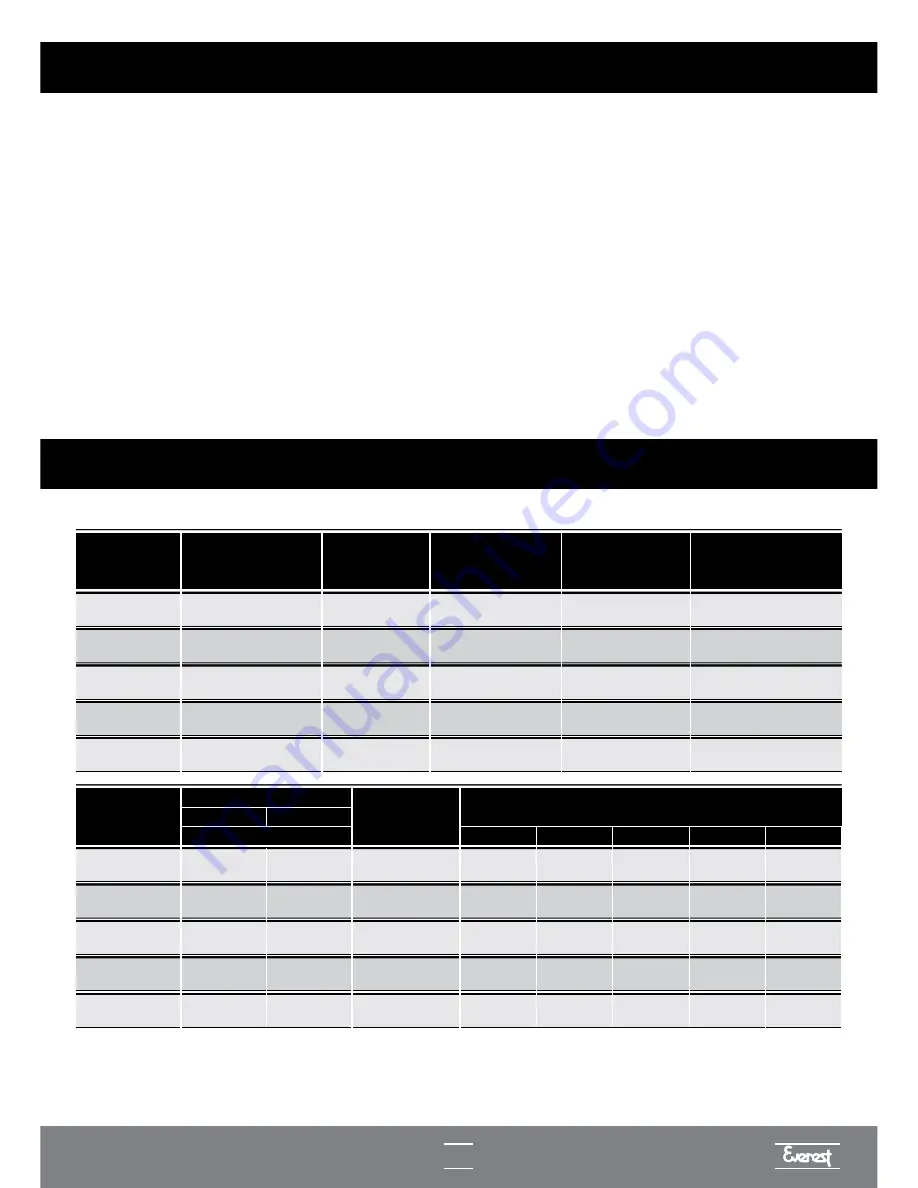

GENERAL TECHNICAL CHARACTERISTICS

MODELO

DIMENSÕES

(A/L/P) cm

COMPRESSOR

(HP NOMINAL)

MASSA DO

APARELHO

GÁS

(HFC)

MASSA DO GÁS

REFRIGERANTE

EGC

75A

EGC

150A

111 x 89 x 54

78 kg

2 x 1/3

R-134a

2 x 225 g

MODEL

DIMENSIONS

(A/L/P) cm

COMPRESSOR

(NOMINAL HP)

DEVICE

WEIGHT

GAS

(HFC)

WEIGHT OF

REFRIGERANT GAS

EGC

50A

EGC

75A

EGC

100A

EGC

150A

EGC

150MA

61 x 45 x 54

111 x 57 x 54

111 x 89 x 54

111 x 89 x 54

63 x 93 x 35

32 kg

49 kg

61 kg

76 kg

60 kg

1/4

1/3

1/3

2 x 1/3

2 x 1/3

R-134a

R-134a

R-134a

R-134a

R-134a

175 g

220 g

350 g

2 x 225 g

2 x 220 g

MODELO

DIMENSÕES

(A/L/P) cm

COMPRESSOR

(HP NOMINAL)

MASSA DO

APARELHO

GÁS

(HFC)

MASSA DO GÁS

REFRIGERANTE

EGC

75A

EGC

150A

111 x 89 x 54

78 kg

2 x 1/3

R-134a

2 x 225 g

MODEL

POWER

watts

PRODUCTION: kg/24hours

at room temperature

EGC

50A

EGC

75A

EGC

100A

EGC

150A

EGC

150MA

380

630

647

1256

1230

VOLTAGE

5.4 A

9.4 A

9.5 A

-

-

ELECTRICAL CURRENT

127V

220V

32ºC

2,7 A

4.7 A

4.6 A

9.3 A

9.3 A

27ºC

22ºC

37ºC

42ºC

48

50

52

42

36

76

80

82

70

62

98

108

114

84

70

152

160

166

140

122

144

158

162

130

101

Summary of Contents for EGC 100 A / 150 A

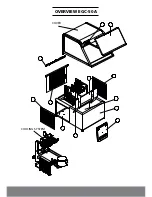

Page 12: ...OVERVIEW EGC 50A COVER COOLING SYSTEM...

Page 14: ...13 I OVERVIEW EGC 150MA I...

Page 15: ...14 COOLING SYSTEM EGC 50A EGC 75A EGC 100A AND EGC 150A I COOLING SYSTEM EGC 150MA I...

Page 16: ...ELECTRICAL ELECTRONIC PART...

Page 17: ...TROUGH DISPLACEMENT SYSTEM DISPLACEMENT ARM ASSEMBLY TROUGH...

Page 36: ...35...