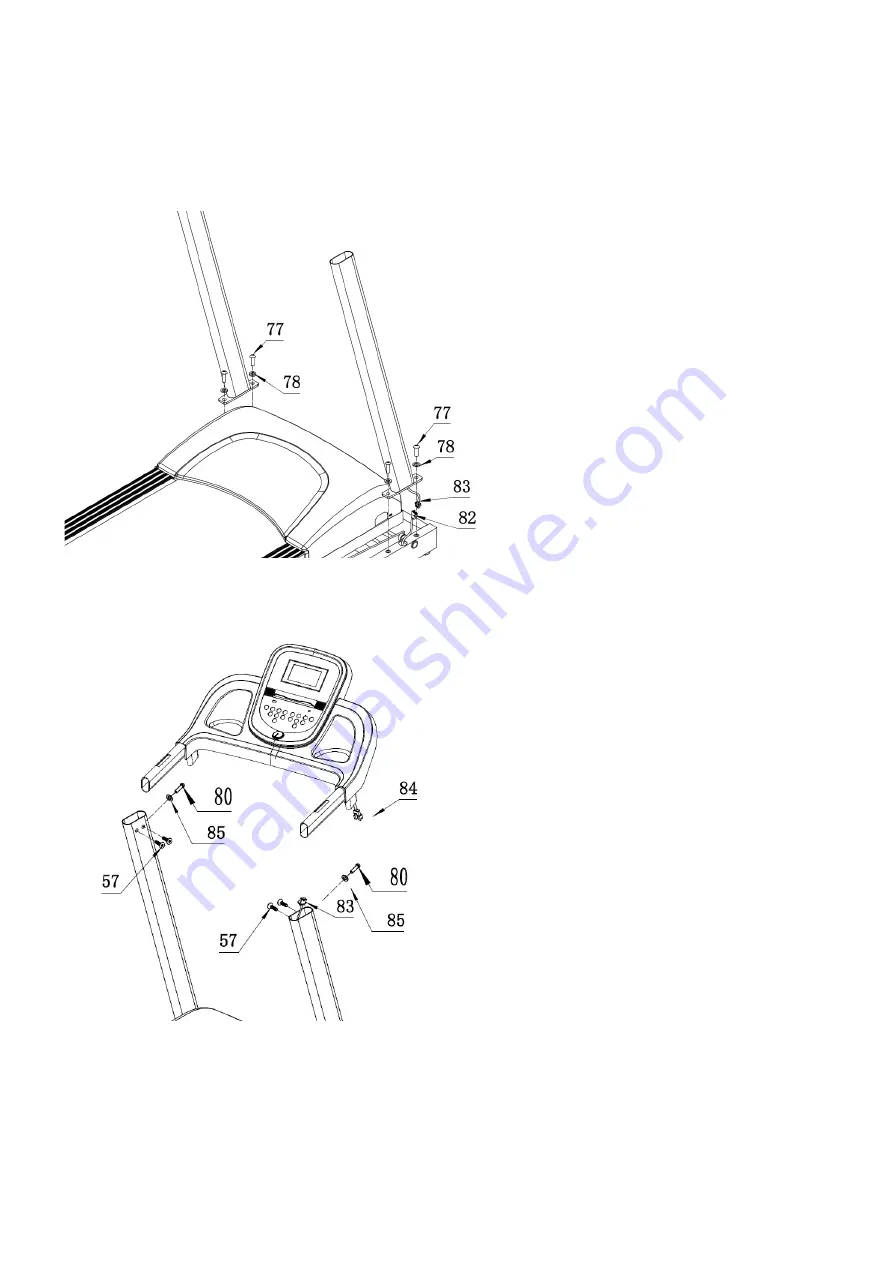

ASSEMBLY INSTRUCTIONS

WARNING: Please put on all the screws, washers and bolts then tighten them.

STEP1:

First

make

to

connect

the

communication cable.

Then fix the uprights on the base

frame with M10*20 ALLEN HEAD

BOLT 77 and

Φ10 WASHER 78..

STEP2:

First

make

to

connect

the

communication cable.

Fix the computer on the uprights with

ST2.9*8 SCREW 57

、

φ8 ARC

WASHER 85 and M8*25 ALLEN

HEAD BOLT 80..