• When working with panels in light, follow all applicable regulation

regarding working with live electrical equipment.

• Do not touch electrical terminals or the ends of any wire while the

panel is exposed to light or while installing the panel.

• Do not wear metallic jewelry while performing mechanical or

electrical installation.

• Never open electrical connections or unplug connectors while the

circuit is under load.

• Contact with electrically active parts of the panels, such as terminals,

can result in burns, sparks and lethal shock whether the panel is

connected or disconnected.

• Always use insulated tools and rubber gloves that are approved for

working on electrical installations.

Fire Safety

• Refer to your local authority for guidelines and requirements for

building or structural fire safety.

• The roof construction and installation may affect the fire safety of

a building; improper installation may contribute to hazards in the

event of fire.

• For roof application, the panels should be mounted over a fire

resistant covering rated for the application.

• It may be necessary to use components such as earth ground fault

circuit breakers, fuses and circuit breakers.

• Do not use panels near equipment or locations where flammable

gases can be generated or can collect.

Electrical Installation

• Avoid all electrical hazards when installing, wiring, operating and

maintaining a panel.

• If the total DC system voltage exceeds 100V, the system must be

installed, commissioned and maintained by a licensed electrician

unless local electrical codes determine otherwise.

• Contact with a DC voltage 30V or more is potentially hazardous.

• Do not use panels of different electrical or physical configurations

in the same system.

• The maximum open circuit voltage of the system must not be

greater than the specified maximum system voltage for the panel.

• All Evergreen Solar panels are equipped with factory-installed wires

and quick connectors. Panels have been designed to be easily

interconnected in series.

• Evergreen Solar ES-A series panels are equipped with Multi-

Contact

®

Type 4 clickable connectors. In order to comply with

the 2008 National Electric code for accessible arrays, the plug

connection must be secured with the UL approved, pluggable

safety lock clip (PV-SSH4) supplied by Multi-Contact

®

.

• The PV-SSH4 clip is not provided by Evergreen Solar and must

be purchased separately. Once the clip is installed, the PV plug

connection can only be unlocked with the use of the PV-MS tool,

also supplied by Multi-Contact

®

.

• Evergreen Solar ES-A series panels are equipped with 10AWG,

UL4703 certified PV-WIRE which enables the panels to be used in

electrically ungrounded systems with transformer-less inverters.

• Use system wiring with suitable cross-sectional areas and connectors

that are approved for use at the maximum short-circuit current of

the panel.

• Match the polarities of cables and terminals when making the

connections; failure to do so may result in damage to the panel.

• When reverse currents can exceed the value of the maximum

protective fuse marked on the back of the panel, a properly rated

and certified over-current device (fuse or circuit breaker) must be

connected in series with each panel or string of panels.

• The rating of the over-current device shall not exceed the value of

the maximum protective fuse marked on the back of the panel.

• The panel contains factory installed bypass diodes located inside

the junction box.

• The junction box is not designed or certified to be field accessible

or maintainable and should under no circumstances be opened.

Opening the junction box may void the warranty.

• Panels with a suspected electrical problem should be returned to

Evergreen Solar for inspection and possible repair or replacement

as per the warranty conditions provided by Evergreen Solar.

Grounding

• Panel frames should be connected to an earth ground for safety

and protection from lightning

• The panel frame is provided with grounding holes that accommodate

self-tapping screws. A #10-32 stainless steel thread cutting screw is

required.

• Evergreen panels can also be grounded using third party grounding

washers or clip devices provided the devices are listed and

identified for grounding the metallic frames of PV panels and the

devices are installed in accordance with the manufacturers specified

instructions.

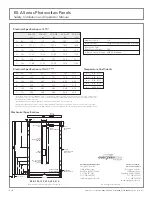

Mechanical Installation

• Panels should be mounted to maximize direct exposure to sunlight

and to eliminate or minimize shadowing.

• Even partial shadowing can substantially reduce panel and system

output.

• Panels must be securely fastened using support frames or mounting

kits specialized for PV applications.

• Panels may be mounted at any angle from vertical to horizontal

orientation.

• Care must be taken to avoid low tilt angles which may cause dirt to

build-up on the glass against the frame edge.

• Dirt build-up on the surface of the panel can cause active solar cells

to be shaded and electrical performance to be impaired.

• Contact Evergreen Solar for more information regarding minimum

recommended tilt angles for specific panel products.

• For roof mounted systems, provide adequate rear ventilation under

a panel for cooling (100mm: 4 in. gap minimum).

• Clearance of 7mm: ¼ in or more between panels is required to

allow for thermal expansion of the frames.

• Always keep the back surface of the panel free from any foreign

objects or structural elements which could come into contact with

the panel, especially when the panel is under mechanical load.

2 of 4

Valid from 1

st

September 2008 / IM-ES-A_US_010908_ETL © 2008 Evergreen Solar, Inc.

ES-A Series Photovoltaic Panels

Safety, Installation and Operation Manual