Installation Instructions

1. Before you start installing the solar water heater, please read

carefully all the installation instructions stated and illustrated

in this manual.

2. Before the installation of the solar water heater, it is very

important that the customer and the installer agree on all

the details concerning the correct and safe installation of the

appliance, (such as location, placement point, static resist-

ance and control of the surface on which the appliance will

be placed, piping and wiring run etc).

3. The installation should be done according to the local electric

and plumbing regulations.

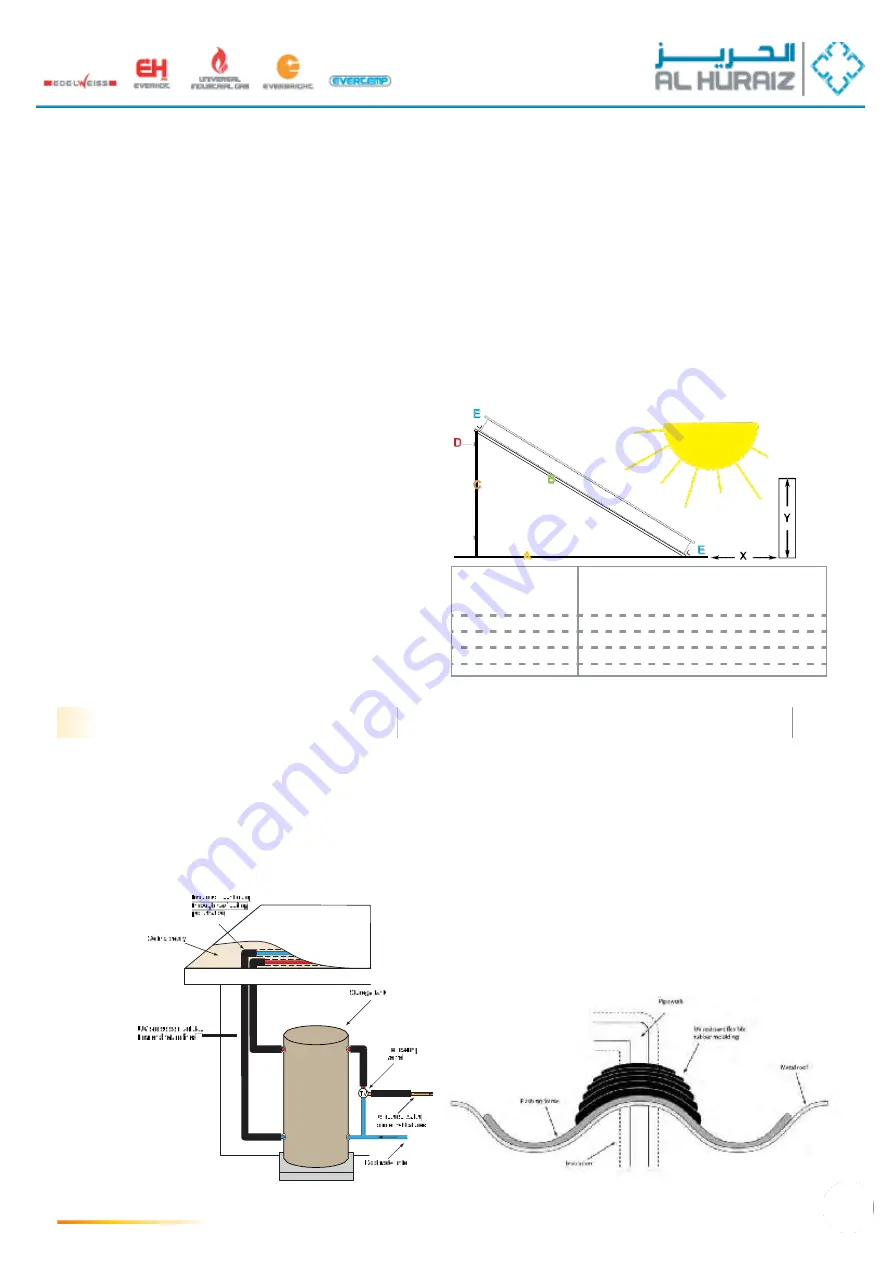

4. The location you will choose for the installation of the solar

collector(s) should not be shaded by any obstacles (trees,

buildings...etc.) all around the year. (see obstacle table here

below).

5. For optimum performance of the solar system, the

collector(s) must face South, for countries located in the

Northern hemisphere and North for countries located in

the Southern hemisphere. In case that it is not totally

possible for the solar collector(s) to face the equator,

you must turn it (them) towards East up to 30º if major

hot water draw is before 14:00 p.m., or towards West

up to 30º if major hot water draw is after 14:00 p.m.

The ideal inclination of the solar collector(s) should be equal

to the latitude in which the installation is done.

6. The support base of the collector(s) is the same for both

flat and inclined roofs. It is diversified only in the way of

it’s assembly (see installation instructions on the following

pages.)

7. If the surface on which the solar collector(s) will be installed

(inclined or flat) is not compatible with the standard equipment

supplied with each appliance, then alternate equipment must

be used. The installer has to choose, propose and install this

alternate equipment, always under the concurrent opinion of

the customer.

8. For installation on an inclined roof, the «D» plates must be

screwed with the appropriate screws and nuts on the roof

timber, in order to secure the right and safe installation of

the collector(s).

9. In regions subject to heavy snowfalls, rainfall, storms, strong

winds, cyclones, tornadoes it is very important to ensure

that the supports of the standard equipment are sufficient to

withstand the weight of the expected snow or the intensity of

the weather conditions. In these cases the collector(s) must

be placed in a stable way on the roof and must be tightened

with additional metal straps.

Continuity in pipe work insulation must be maintained,

although, sometimes, many lengths may need to be joined to

cover the full length of pipe work. In those instances, the join

should be taped and UV-resistant tape used where the join

is made on external pipe work.

Where pipe work penetrates the roof material, the

insulation should go through the penetration with the pipe

work, as shown in figure on the right.

Roof penetrations for pipe work, electrical conduits or

support frames should be sealed with roof lashings to

prevent water leaking into the roof cavity. These lashings are

usually made of EPDM or silicon rubber, with an aluminum

frame that can be mounded to the shape of the roof, as

shown in figure below.

Where possible, penetration should

be done on the high part of the roof profile to avoid the

possibility that water will pool around a penetration that

is located in the valley

of the profile.

Lead lashing should not be used on a roof that is collecting

rainwater for drinking and it must be compatible with other roof

cladding material.

Roof penetration (cross-section)

Insulation continuity

through roof

penetrations

27

Roof flashings

Insulation considerations

latitude

0º- 25º

Distance between

collector and obstacle

X = 1,0 x Y

25º- 35º

X = 1,5 x Y

35º- 45º

X = 2,0 x Y

45º- 50º

X = 2,5 x Y

50º +

X = 3,0 x Y

Summary of Contents for 1000/BL1

Page 1: ......

Page 12: ...CLIMATIC DATA OF SELECTED WORLD CITIES 12...

Page 13: ...Energyoutputofthecollectorinseveralcitiesoftheworld inkWh m2 13...

Page 30: ...Assembly diagram of the support base for one 30...

Page 34: ...Assembly diagram of the support base for three 34...

Page 37: ...Connectionofcollectorsandaccessories 37...

Page 39: ...HYDRAULIC KIT 39...