SERVICE

MANUAL

Tankless Gas Water Heater

Troubleshooting Guide

and Instruction for Service

(To be performed ONLY by qualified service providers)

For the LAARS

®

Heating System

EverHot

®

Exterior Tankless

Gas Water Heater Models:

IGE-199R-10(N,X)

IGE-199C-5(N,X)

Document 11014

Save this manual for future reference

Summary of Contents for IGE-199C-5N

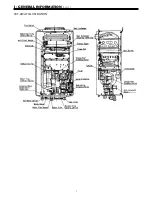

Page 7: ...I GENERAL INFORMATION cont CUT AWAY ILLUSTRATION 7...

Page 8: ...I GENERAL INFORMATION cont SCHEMATIC ILLUSTRATION 8...

Page 19: ...V SEQUENCE OF OPERATION cont OPERATION SEQUENCE FLOW CHART 19...

Page 20: ...20 V SEQUENCE OF OPERATION cont OPERATION SEQUENCE FLOW CHART...

Page 21: ...V SEQUENCE OF OPERATION cont SEQUENCE TIMING CHART 21...

Page 22: ...22 V SEQUENCE OF OPERATION cont SEQUENCE TIMING CHART...

Page 28: ...VI TROUBLE SHOOTING cont WIRING SCHEMATIC 28...

Page 53: ...X PARTS BREAKDOWN DISASSEMBLED VIEW CABINET 53...

Page 54: ...X PARTS BREAKDOWN DISASSEMBLED VIEW INTERNALS 54...

Page 55: ...X PARTS BREAKDOWN DISASSEMBLED VIEW INTERNALS 55...

Page 56: ...X PARTS BREAKDOWN DISASSEMBLED VIEW ELECTRICAL 56...

Page 59: ...59 Notes...