24

VI - TROUBLESHOOTING

(cont.)

ERROR MESSAGES

Error Faulty

Remedy

32

Outgoing Water

Check sensor wiring for damage.

Temperature Sensor Faulty

Check resistance on sensor.

Check and clean scale from sensor.

Replace sensor.

33

Heat Exchanger Outgoing

Check sensor wiring for damage.

Temperature Sensor Faulty

Check resistance on sensor.

Check and clean scale from sensor.

Replace sensor.

34

Combustion Air

Check sensor wiring for damage.

Temperature Sensor Faulty

Check resistance on sensor.

Check and clean dirt from sensor.

Ensure fan blade is tight on motor shaft and it is in good

condition. Clean blower blades if dirty.

Check for restrictions in air flow around unit and vent terminal.

Replace sensor.

52

Modulating Solenoid Valve

Check modulating gas solenoid valve wiring harness for loose

Signal Abnormal

or damage terminals.

Check resistance on solenoid valve.

61

Combustion Fan Failure

Ensure fan motor will turn freely. Motor will operate with a

small amount of restriction.

Check wiring harness to motor for damaged and/or loose

connections.

Check resistance on motor winding.

71

SV0, SV1, SV2, and SV3

Check wiring harness to all solenoids for damage and/or loose

Solenoid Valve Circuit Faulty

connections.

Check resistance on each solenoid.

72

Flame Sensing Device Faulty

Check micro amps produced by flame rod.

Remove flame rod and check for carbon build-up, clean with

sand paper.

Ensure flame rod is touching flame when unit fires.

Check inside burner chamber for any foreign material blocking

flame at flame rod.

Check all wiring to flame rod for damage.

Replace flame rod.

LC

Scale Build-up in Heat Exchanger

Turn off power supply, then reapply power; if code does not

reappear separate control wires from the unit's power supply.

Flush heat exchanger.

Replace heat exchanger.

No

Nothing happens when water flow

Clean inlet water supply filter.

Code

is activated

Ensure you have at least the minimum flow rate required to fire

unit.

Check for pipe dope inside water flow control turbine.

On new installations ensure hot and cold water lines are not

crossed.

Check for bleed over. Isolate unit from building by turning off

hot water line to building, then open your pressure relief valve.

If unit fires, there's a bleed over in your plumbing.

If a circulating system is in use, it must be isolated also.

Remote control does not light up but you have 12 VDC at the

terminals for controls.

Disconnect water flow control motor, then turn on hot water, if

unit fires replace water flow control assembly.

Check resistance on water flow control sensor.

Summary of Contents for IGE-199C-5N

Page 7: ...I GENERAL INFORMATION cont CUT AWAY ILLUSTRATION 7...

Page 8: ...I GENERAL INFORMATION cont SCHEMATIC ILLUSTRATION 8...

Page 19: ...V SEQUENCE OF OPERATION cont OPERATION SEQUENCE FLOW CHART 19...

Page 20: ...20 V SEQUENCE OF OPERATION cont OPERATION SEQUENCE FLOW CHART...

Page 21: ...V SEQUENCE OF OPERATION cont SEQUENCE TIMING CHART 21...

Page 22: ...22 V SEQUENCE OF OPERATION cont SEQUENCE TIMING CHART...

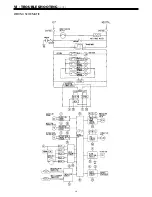

Page 28: ...VI TROUBLE SHOOTING cont WIRING SCHEMATIC 28...

Page 53: ...X PARTS BREAKDOWN DISASSEMBLED VIEW CABINET 53...

Page 54: ...X PARTS BREAKDOWN DISASSEMBLED VIEW INTERNALS 54...

Page 55: ...X PARTS BREAKDOWN DISASSEMBLED VIEW INTERNALS 55...

Page 56: ...X PARTS BREAKDOWN DISASSEMBLED VIEW ELECTRICAL 56...

Page 59: ...59 Notes...