42

a.

# Disconnect the modulating valve festoon C2

terminals and measure the resistance at the terminals.

Normal: 67 ~ 81 Ω

If normal, check b.

Faulty: Replace gas valve.

(Service Procedure IGE-9, page 50)

b.

Re-connect terminal C2 and measure voltage

across the pink ~ pink wires when the unit is firing.

Normal: 2 ~ 15 VDC

If normal, check c below.

Faulty: Replace the PCB unit.

(Service Procedure IGE-2, page 47)

c.

Investigate the change in the manifold gas

pressure, when the remote control pre-set

temperature is altered from 96 ~ 140 ºF.

Normal: If the manifold pressure changes,

proceed to check item 4 below.

DO NOT

adjust manifold pressures.

Faulty: Replace gas valve.

(Service Procedure IGE-9, page 50)

a.

# Disconnect connector B2 and measure the

resistance of the water flow servo, red ~ blue wires.

Normal:

22 ~ 26 Ω

If normal, proceed to b.

Faulty:

Replace the water flow servo and sensor.

(Service Procedure IGE-2, page 47)

b.

Disconnect connector B2 , and measure the

voltage on the PCB unit side, were the orange

(+), and/or grey or black (-) wires connect to the board.

Normal:

3.3 ~ 4.5 VDC

If normal, proceed to c.

Faulty:

Replace the PCB unit.

(Service Procedure IGE-2, page 47)

c.

With connector B

2

, connected (do not turn water

ON … wait for the water flow servo to return to

fully open), measure the voltage at the brown ~

grey wires.

Normal:

4 ~ 6 VDC vent limiter OFF

Faulty:

Replace the water flow servo and sensor.

(Service Procedure IGE-2, page 47)

d.

With connector B2 , connected (do not turn

water ON… wait for the water flow servo to

return to fully open), measure the voltage at the

yellow ~ grey wires.

Normal:

Less than 0.5 VDC when unit is set at

120 °F and there is no water flowing through the unit.

Faulty:

Replace water flow servo and sensor.

(Service Procedure IGE-2, page 47)

3) Is the modulating valve operating normally? Error code 52

4) Is the water flow servo normal?

BEFORE CARRYING OUT CHECKS MARKED WITH A # SIGN, DISCONNECT THE POWER SUPPLY.

Summary of Contents for IGE-199C-5N

Page 7: ...I GENERAL INFORMATION cont CUT AWAY ILLUSTRATION 7...

Page 8: ...I GENERAL INFORMATION cont SCHEMATIC ILLUSTRATION 8...

Page 19: ...V SEQUENCE OF OPERATION cont OPERATION SEQUENCE FLOW CHART 19...

Page 20: ...20 V SEQUENCE OF OPERATION cont OPERATION SEQUENCE FLOW CHART...

Page 21: ...V SEQUENCE OF OPERATION cont SEQUENCE TIMING CHART 21...

Page 22: ...22 V SEQUENCE OF OPERATION cont SEQUENCE TIMING CHART...

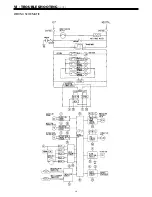

Page 28: ...VI TROUBLE SHOOTING cont WIRING SCHEMATIC 28...

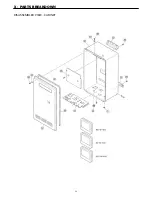

Page 53: ...X PARTS BREAKDOWN DISASSEMBLED VIEW CABINET 53...

Page 54: ...X PARTS BREAKDOWN DISASSEMBLED VIEW INTERNALS 54...

Page 55: ...X PARTS BREAKDOWN DISASSEMBLED VIEW INTERNALS 55...

Page 56: ...X PARTS BREAKDOWN DISASSEMBLED VIEW ELECTRICAL 56...

Page 59: ...59 Notes...