18

ENGLISH

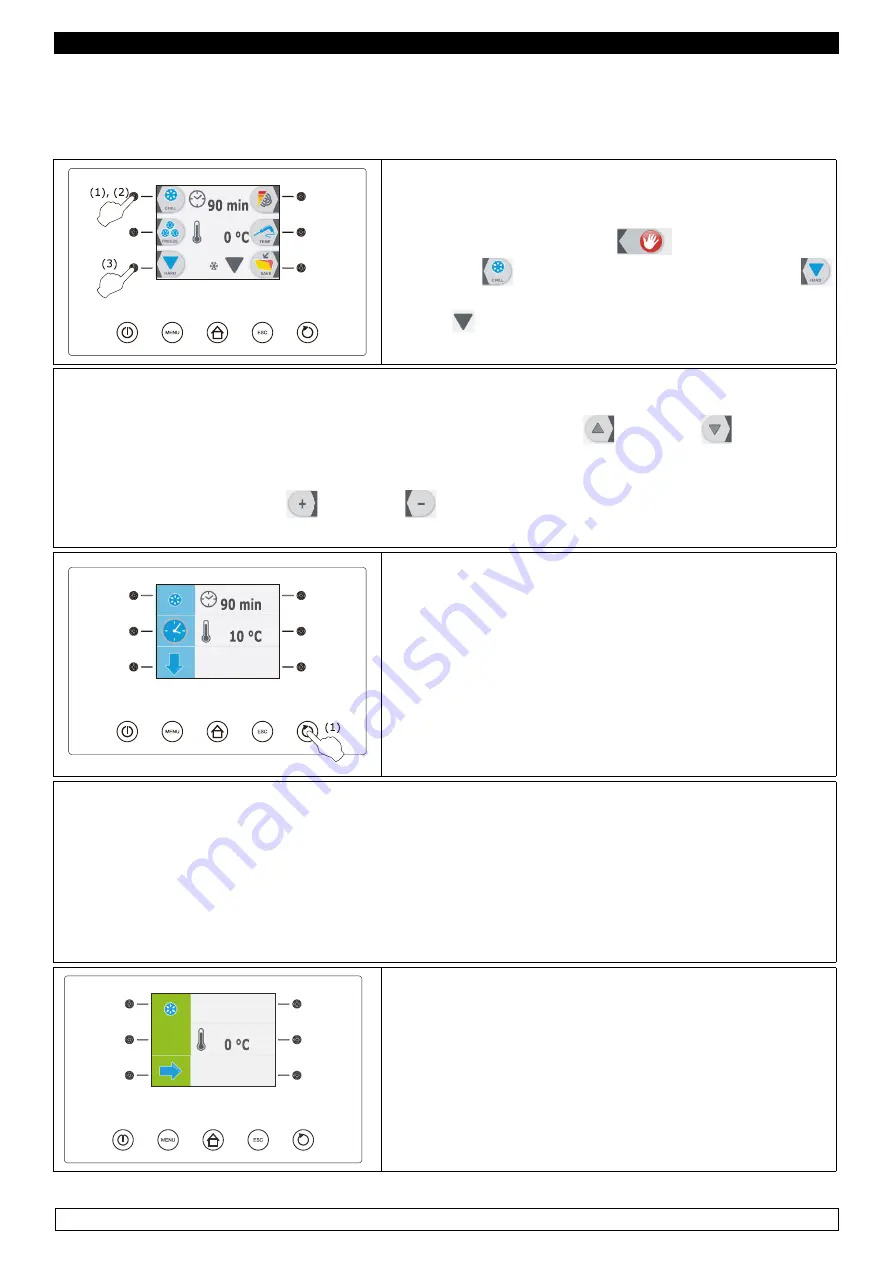

When a phase is over the control panel automatically switches to the next step.

To start the cycle proceed as follows:

►

Make sure the display is in the “ON” mode.

►

Make sure the keyboard is not locked and no procedu-

re is currently under process.

►

Press and release the key

(1), press and rele-

ase the key

(2), than press and release the key

(3): in order the displaymodo che sul display compaia il

simbolo

The display will show the duration of the cooling phase and the running temperature during the cooling

process.

►

Press and release the MENU key, then press and release the key

or the key

to select the

duration of the cooling phase and the running temperature during the cooling process, other than

the set one.

►

Press and release the key

or the key

to modify these values then press the ESC key to

store them.

Program: MANUAL

Elapsed time: 0 min

►

Press and release the START / STOP key (1) : the

cycle will start.

►

During the hard cooling phase, the display will show

the remaining time of the cooling phase, the cell tem-

perature, the name of the program (if any) and the time

elapsed since the starting of the cooling process.

►

Hold the START/STOP key pressed for 3 seconds to

stop the cycle.

►

When the hard cooling phase is over the control panel will automatically switch to the cooling

phase.

►

During the cooling phase the display will show the remaining time of the cooling phase , the cell

temperture, the name of the program (if any) and the time elapsed since the starting of the cooling

process.

►

When the cooling phase is over the control panel will automatically switch to the preservation

phase and the buzzer will sound. To silence buzzer press and release any key.

Program: MANUAL

Cycle time: 90 min

End

►

During the preservation phase the display will show the

cell temperture, the name of the program (if any) and the

cooling process duration.