12. The surface oxide layer of the frame may be damaged by sharp objects, do not

destroy or scratch the frame of the modules.

13. Glass surface, back-sheet and aluminum frame are susceptible to damage that could

affect the performance or integrity of the PV module; do not damage or scratch the

surfaces, and do not spray any non-validated chemicals paints, solvents or adhesive to

any of the surfaces, including the frame. Doing so may degrade performance or cause

irreparable damage and will void any applicable warranties.

6. Installation

1.

The electrical and mechanical installation must be comply with international and

local standards and principles including cable connection building codes etc.

2.

The mounting structures must be designed by qualified structural engineers, and

installation design and procedures shall be consistent with the relevant local

standards.

3.

Installers must be qualified and familiar with solar and electrical principles.

4.

The working ambient temperature range is -40℃ to +85℃ and Relative Humidity

≤85%.

5.

The modules shall be installed so as to maximize solar exposure and to minimize

shading by trees, buildings or other obstacles in the surrounding area. Generally in

the Northern hemisphere modules are ideally orientated to the south and in the

southern hemisphere modules orientated to the north.

6.

Notify Eversola of any damage to product immediately. Do not use or install

damaged modules. Damaged modules may cause fire or electric shock, resulting in

property damage, fire and or death.

7.

Do no disconnect or connect any cables under load, the bending cable radius of

Junction box must more than 43mm.

8.

Match the polarities of cables and terminals when making the connections, failure to

do so may result in damage to the module. Keep the connector dry and clean and

do not impact external force on the connector such as heavy snow, strong wind.

9.

The maximum modules of one PV string N=(The maximum system

voltage)/[(Voc)*1.25], note the Voc is the value at the lowest temperature in the

project sites.

10. Suitable over current protection devices (string fuses etc.) must be installed when

connecting 3 or more strings in parallel configuration.

11. Under normal conditions, a module may be able to produce voltage and current

higher than in standard test condition. Accordingly, when determining component

rated voltage, conductor ampacities, fuse current and size of controls connected to

the PV output, the short circuit current and open circuit voltage value marked on

this module shall be multiplied by a factor (safety factor) of 1.25.*

·06·

·05·

*Note:

The safety factor for component rated voltage, conductor ampacities, fuse

current and size of controls connected to the PV output is subject to the

meteorological conditions of project sites.

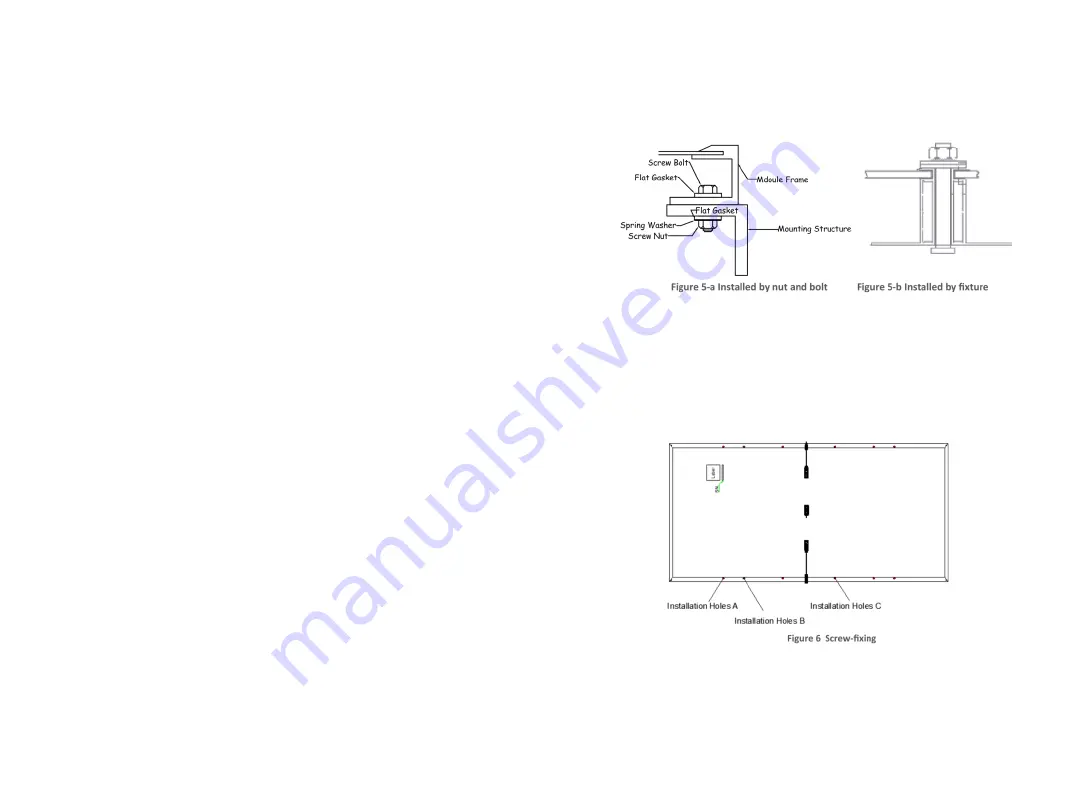

12. Select either method of fixing mentioned below depending on site conditions:

Screw-fixing system (Figure 5-a), Fixture-fixing system (Figure 5-b).

13. Installation method and location

1)

Screw-fixing:

Fixing the modules on the bracket at 12 border prefabricated installation holes

(figure 6). All the fastening pieces are made of stainless steel. Installing holes A must

be fixed with bolts and customer can choose one of the installation B or C to use.

Applied torque is recommended as 7-11 N*m for M6 (diameter is 6mm) screw in

installation holes C and 14-20 N*m for M8 (diameter is 8mm) screw in installation holes

A&B.

2) Fixture-fixing:

Fix the module safely and securely on the mounting structure. The length of clamp

should be 40mm minimum. Applied torque is recommended as 7-11 N*m for

M6(diameter is 6mm) screw. The clamp are made of aluminum alloy.