6

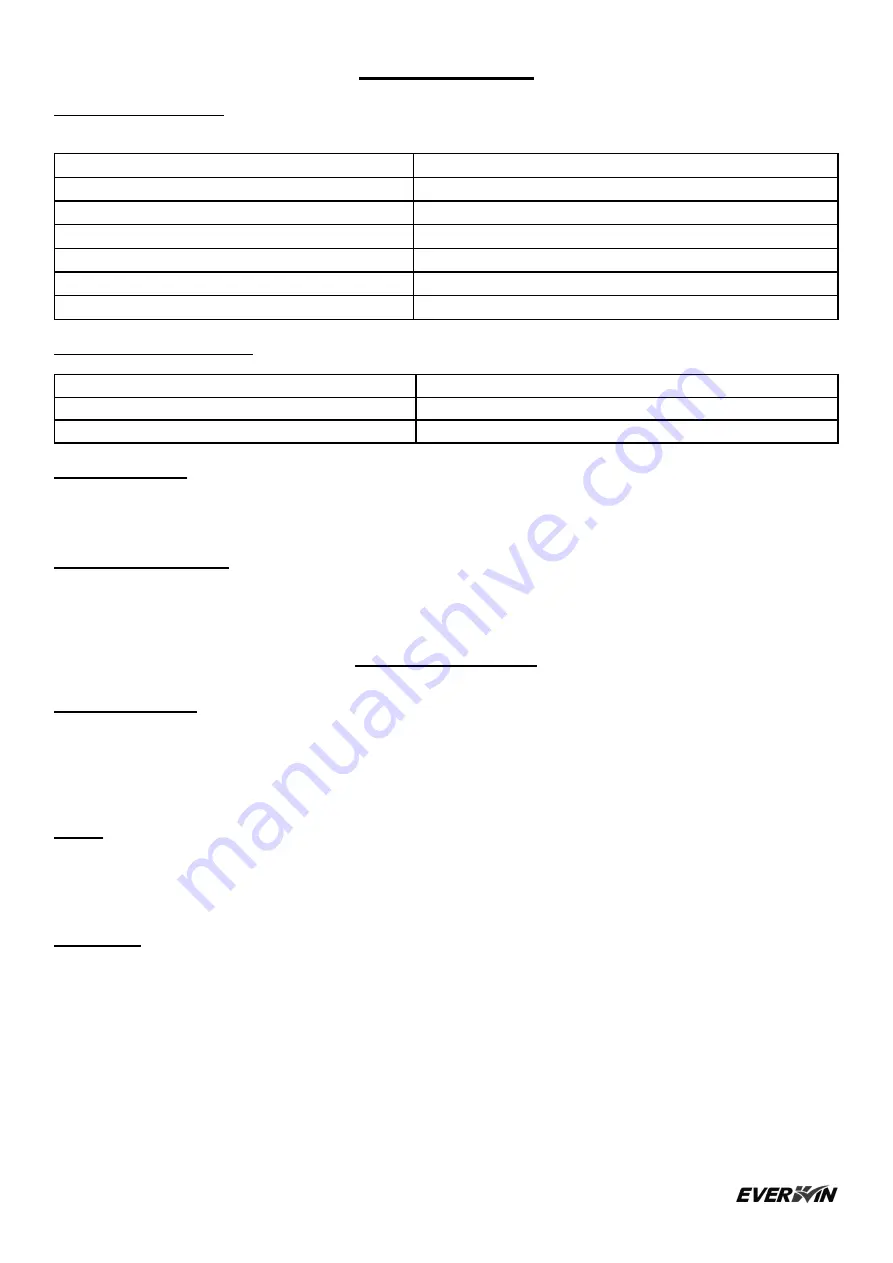

SPECIFICATIONS

TOOL SPECIFICATIONS

HEIGHT

15.7" (398 mm)

WIDTH

5.5" (139 mm)

LENGTH

14.2" (360 mm)

WEIGHT

15.0 lbs. (6.8 kg)

RECOMMENDED OPER. PRESSURE

70 to 120 PSI (5 to 8 bar)

LOADING CAPACITY

225 Nails

AIR CONSUMPTION at 90 PSI (6 bar) pressure

3.6 cfm (1.7 liter/sec)

FASTENER SPECIFICATION

NAIL LENGTH

1-7/8" (47.6 mm)

SHANK DIA.

.113" (2.9 mm)

SHANK TYPE

Smooth

TOOL AIR FITTING

This tool uses a 1/4”-18 N.P.T. or 1/4”-19 P.T. male plug. The inside diameter should be .280” (7 mm) or larger. The

fitting must be capable of discharging tool air pressure when disconnected from the air supply.

OPERATING PRESSURE

70 to 120 PSI (5 to 8 kg/cm

2

). Select the operating pressure within this range for best fastener performance.

DO

NOT EXCEED THIS RECOMMENDED OPERATING PRESSURE.

TECHNICAL DATA

AIR CONSUMPTION

Tool air consumption:

3.6 cfm (1.7 liter/sec.)

of free air to operate at the rate of 100 nails per minute, at 90 PSI (6.0

kg/cm

2

). Take the actual rate at which the tool will be run to determine the amount of air required. For instance, if

your fastener usage averages 50 nails per minute, you need 50% of the tool air consumption in running at 100

nails per minute

NOISE

A-weighted single-event sound power level LWA, 1s, 115.7 dBA

A-weighted single-event emission sound pressure level at work station LpA 1s,d 112.4 dBA

These values are determined and documented in accordance to EN12549.

VIBRATION

Vibration characteristic value= 3.37 m/s

2

These values are determined and documented in accordance to ISO 8662-11.

This value is a tool-related characteristic value and does not represent the influence to the hand-arm-system when

using the tool. An influence to the hand-arm-system when using the tool will, for example, depend on the gripping

force, the contact pressure force, the working direction, the adjustment of mains supply and the workpiece support.