E2630-LEL

Rev 23.03.2021

Operation

During the first ca. 60 seconds after powering on E2630 performs a warming-up and

self-diagnostic routine, indicated by the flashing of each LED. The upper dual-color LED

remains continuously green in normal operation and blinks red in case of device or sensor

fault. The warm-up time depends on the sensor type, unpowered period, and atmosphere.

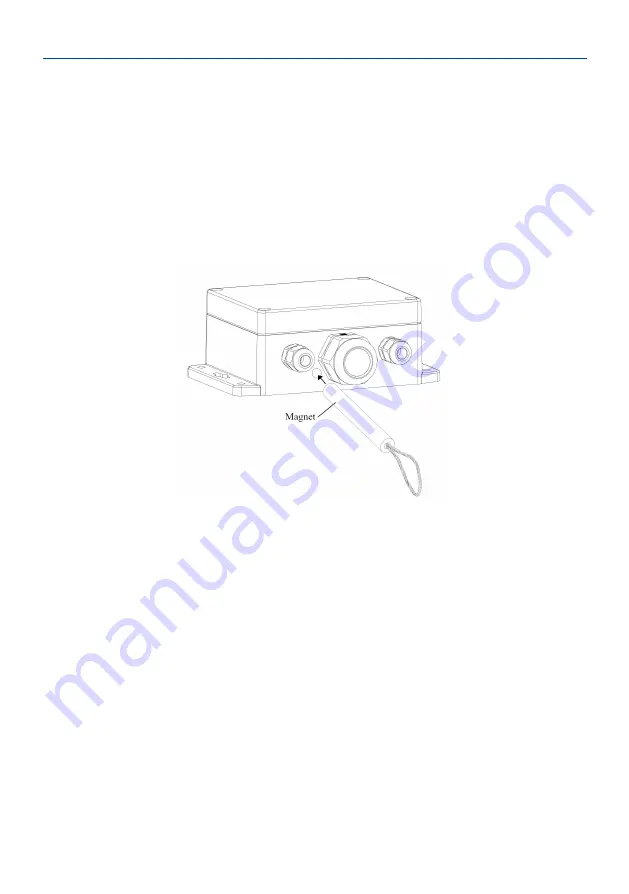

During the first 30 seconds after powering on you may select the automatic or manual

mode of alarm release. Touch the device with the magnet key on the spot shown in the

drawing below.

A short touch (< 2 s) enables the automatic mode, a touch of 2...10 s — manual mode. The

activation of the automatic mode is followed by a single LED blinking and acoustic signal.

If manual mode is activated, the double acoustic and light signal follows.

If the gas concentration exceeds the LOW alarm setpoint, the bottom red LED starts

flashing at a rate of 1 Hz, and the relay RE1 switches over. The first alarm stops

automatically if the gas concentration drops below 70% of the LOW alarm setpoint.

If the gas level exceeds the HIGH alarm setpoint, the bottom red LED starts flashing and

the buzzer starts beeping at a rate of 2 Hz, and also the relay RE2 switches over.

Depending on the selected release mode, the HIGH alarm stops automatically or can be

stopped with a short touch of the magnet key, if the gas level has dropped below 70% of

the LOW alarm setpoint. Upon contact, the key should activate the reed switch located left

of the sensor inside the device.

Apart from the warming-up period, a 2....10 s touch causes the device to reset and perform

the self-diagnostic routine for testing purposes. To check the visual and acoustic alarm,

touch the device with the magnet key for more than 10 s. This will launch blinking and

beeping (stops as soon as the key is withdrawn).

13