24

4

PRIMARY AND SECONDARY CIRCUIT

Prior to the circuits being filled and isolated, they must be fully pressure tested in line with

the design requirements and current regulations.

4.1 Water

treatment

It’s important to prevent

corrosion and oxidisation.

Therefore, the quality and

cleanliness of the water within

both the primary and secondary

circuits is vitally important, to

prevent damage to the Modusat

components and to ensure that

the efficiency and service life of

the unit is maintained.

It is therefore necessary to fully

flush and treat both primary and

secondary circuits using

suitable water treatment chemicals.

Typical water quality guidelines are as follows:

pH – this measures the alkalinity of the water, neutral alkalinity is pH7. Heating systems

require an alkaline pH.

TDS – this measures the dissolved solids in the system and is a measure of the

cleanliness of the water. Recommended levels 0-200 ppm.

Conductivity – this is the measure of the ability of water to pass an electrical current and is

affected by the presence of dissolved solids. Recommended levels 200 crs.

Free copper – this measures the level of copper in the system in mg/litre. Recommended

levels are under 1 mg/l.

Total iron – this measures iron concentration in mg/litre. Recommended levels are under 1

mg/l.

4.2 Cleaning

The cleaning and treatment of the systems must be carried out strictly in accordance with

BSRIA and CIBSE guidelines and the relevant British Standards. It is a requirement that

the following is undertaken:

Clean the boiler room plant.

Cleaning of the primary circuit, with the ModuSat TP isolating valves closed and the

flushing bypass fully opened.

Cleaning of the horizontal pipework and the ModuSat TP unit.

Cleaning of the apartment heating circuit.

Use of a dirt separator in the boiler room and strainer on each ModuSat TP, which is

supplied as part of the valve kit, to provide additional system protection.

During the final fill and treatment the systems must be fully vented to remove all air, and

the system pressure adjusted to design requirements (that form part of the design criteria

and specification). If the tender specification does not enforce a particular standard then

Evinox requirements would be the BSRIA AG 1/2001.1 standard.

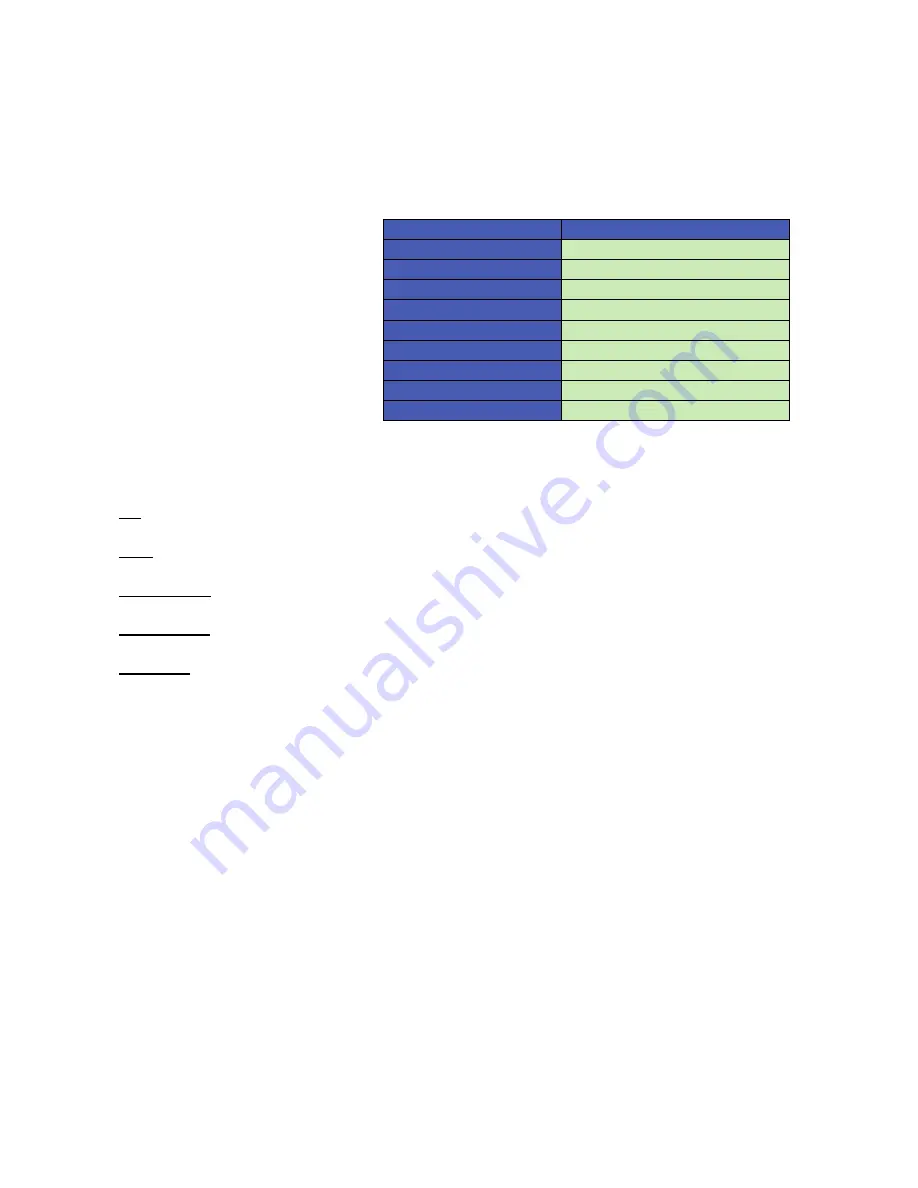

Parameter

Recommended

Hardness (TH)

About 10 °F

Chlorides

Up to 100 mg/l

PH

7 to 8,5

Resistivity

Higher than 2000 Ohm/cm

Salinity

Up to 50 mg/l

Conductivity

200 crs

TDS

0-200 ppm

Iron

Up to 1 mg/l

Copper

Up to 1 mg/l

Typical Water Quality Guidelines